OMEGA PLASTO LIMITED

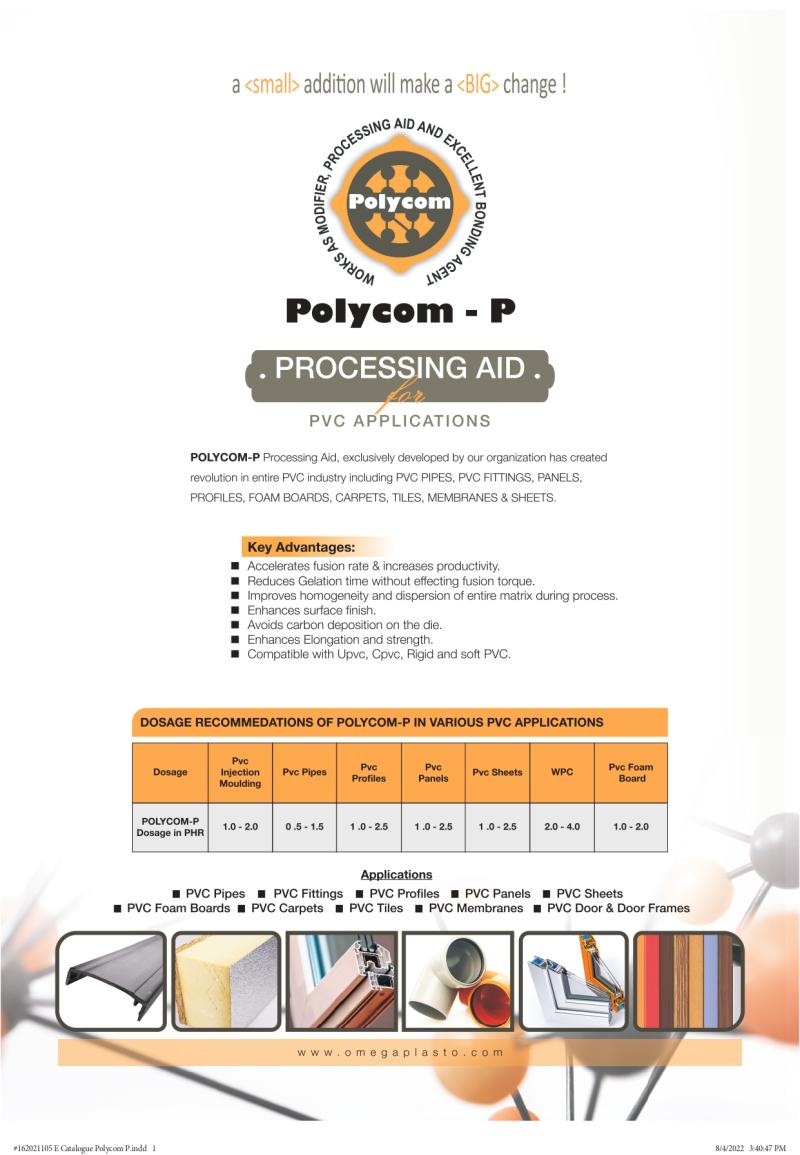

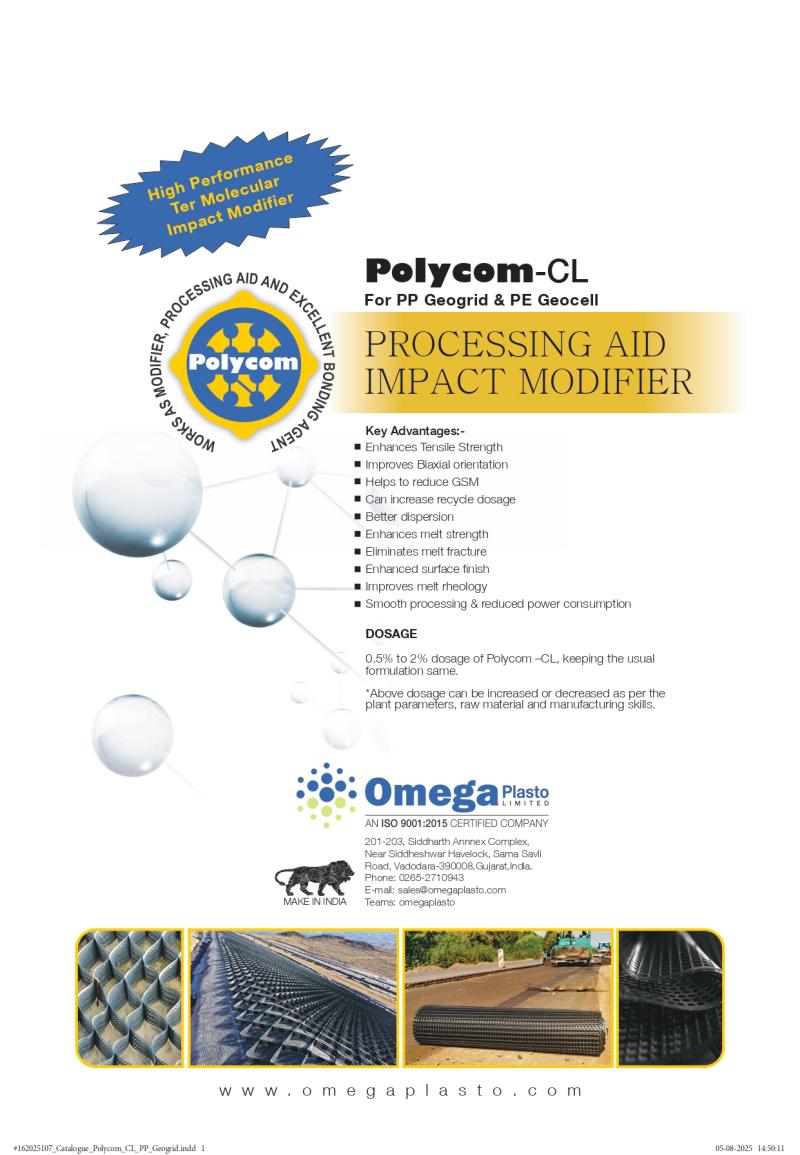

Omega Plasto Ltd. an ISO 9001:2015 certified company based in India has more than a decade of experience in manufacturing specialized wide range of Additives. We have our presence in more than 75 countries which includes our office at Brazil, Russia, Turkey, Uzbekistan and Kazakhstan Latest Modifiers, exclusively developed by our company, namely POLYCOM, has created a revolution in Woven sack, Blown film, Lamination, HDPE Corrugated Pipes, Injection / Blow Moulding, Rotational Moulding industry, Geogrid, Geocell, ABS applications. We have range of specialized processing aid for PVC industry namely Polycom P, Polycom HI and Polycom E which has created a revolution in PVC industries like PVC pipe, Fittings, Profile, Panels and tiles. Reduces Gelation time without reducing fusion torque, improves homogeneity & dispersion, Reduces the cost of production. Using our grade calcium carbonate dosage can be increased to new higher level, which gives huge advantage in raw material cost savings.