| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

ZHEJIANG RUNTAI AUTOMATION TECHNOLOGY CO., LTD

No.358 Kaifa 2nd Road, Ruian Economic Development Zone, Ruian, Wenzhou, Zhejiang / / / CHINA

|

Contact Info: +86 19 ext. 818123605

|

Hall: 11A

Stand: 11A-127G

|

||||||||||||

| Product Groups | ||||||||||||||

|

No product group found |

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

ZHEJIANG RUNTAI AUTOMATION TECHNOLOGY CO.,LTD, was founded in 1997 which is a manufacturer dedicated in researching, manufacturing, marketing and servicing. Further processing plastic and non-woven materials is our general production range and non-standard equipment development is our speciality. We always pursue the quality first, the credibility first business purposes, and constantly respected people-oriented, technology leadership, service-oriented modern enterprise management philosophy. lmprove technical talent, update production equipment, create new products is our pursuit of the goal. All employees to work, innovation, integrity, improve the corporate image. R & D and manufacturing of 8 series, more than 50 kinds of machinery and equipment, fully meet the needs of modern marketenter prises. Excellent equipment quality, marketing at home and abroad, and Japan, SouthKorea, Vietnam, India, Russia, Mexico and other countries have perennial supply contracts. The company has always provided customers with comprehensive production planning, as well as perfect pre-sales technical guidance, after-sales technical support services; To provide customers with high quality products, reasonable prices, fast delivery and enthusiastic service, to win the market.Choose us,choose quality! As Zhejiang High-growth Technology Enterprise and National High-Tech Enterprise

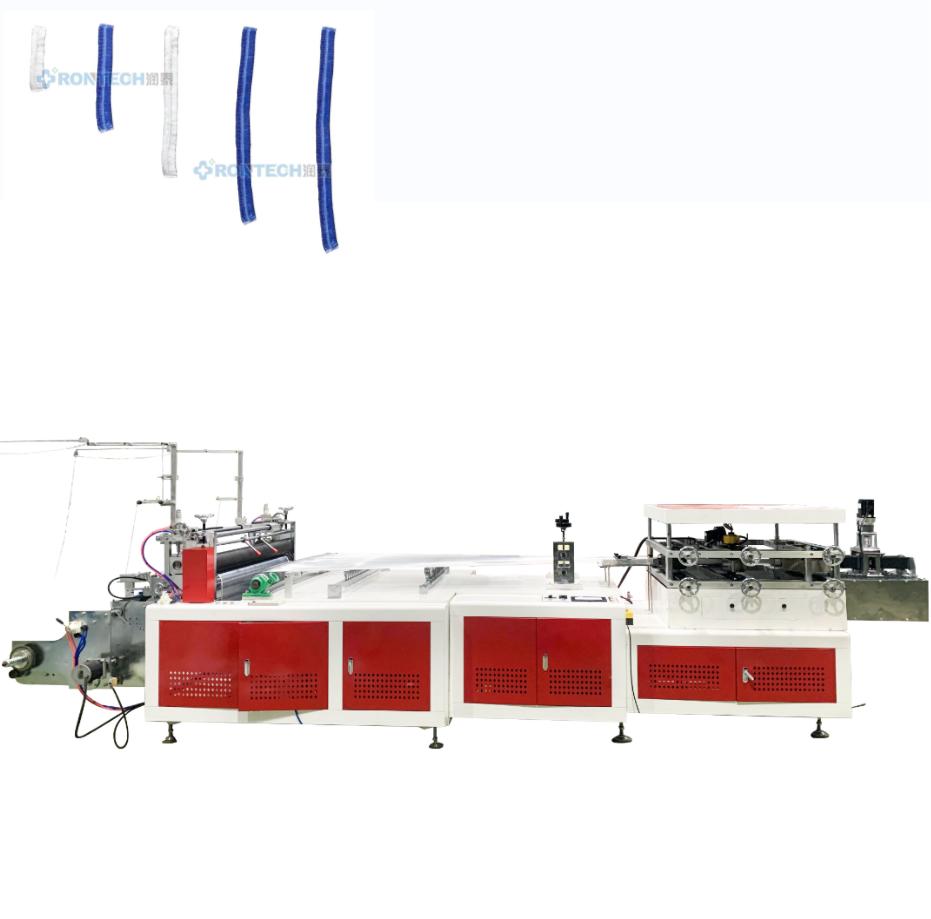

1Controlled by a servo motor, the cuting length is precisely adjustable, and the finished product isfirmly welded. 2.Suitable for HDPE/LDPE and non-woven fabrics, the product length is adjustable, and the applicationrange is wide. 3.From raw material feeding to finished product automation, computer stepless speed regulation, moreflexible operation, only one person is needed for the whole process. 4.Customize models with different feeding widths according to production requirements 5.Automatic constant temperature control. 6.The combination of high-power ultrasonic weldingand electric heating makes the product softer and more comfortable.

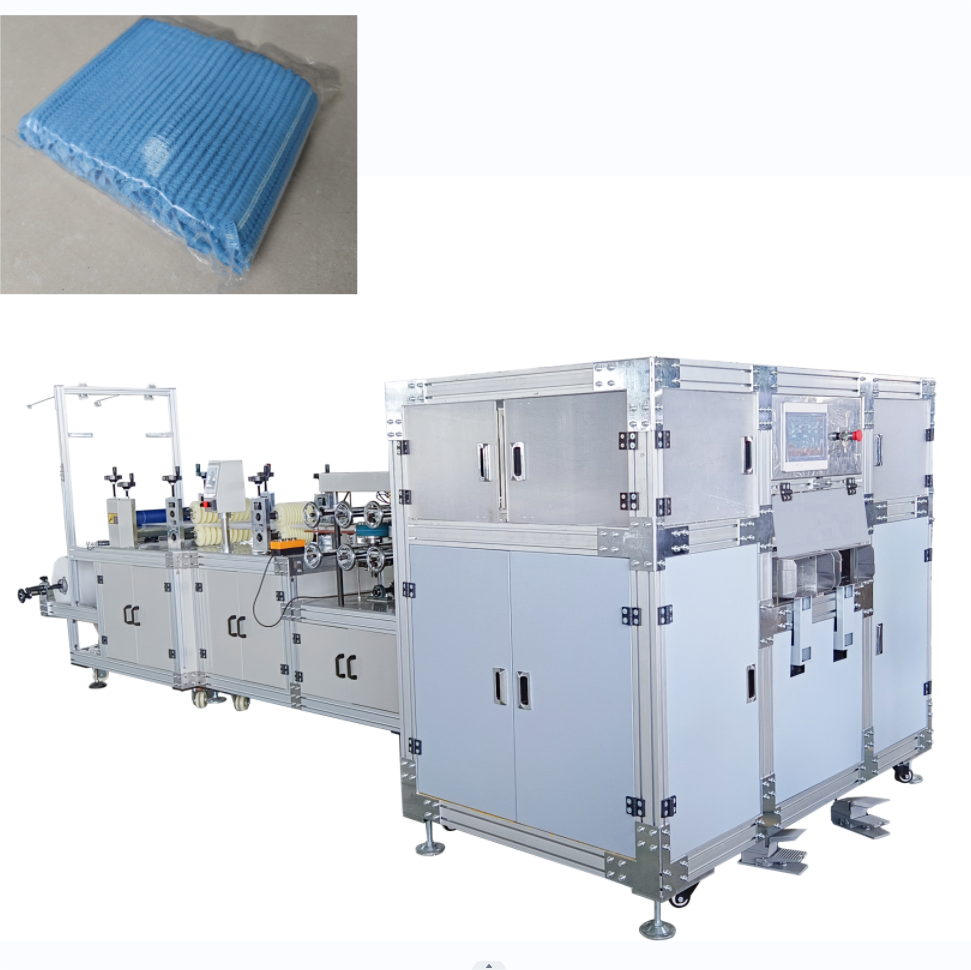

The production line is divided into three parts 1. Surgical gown body machine 2. Surgical gown sleeve machine 3. Ultrasonic sewing machine, which sews the sleeves and the body together

No need for manual counting and packaging, saving labor and time, speed: 120-2-pcs/min

No represented companies found.

The company has no registered brand information.

TR

TR