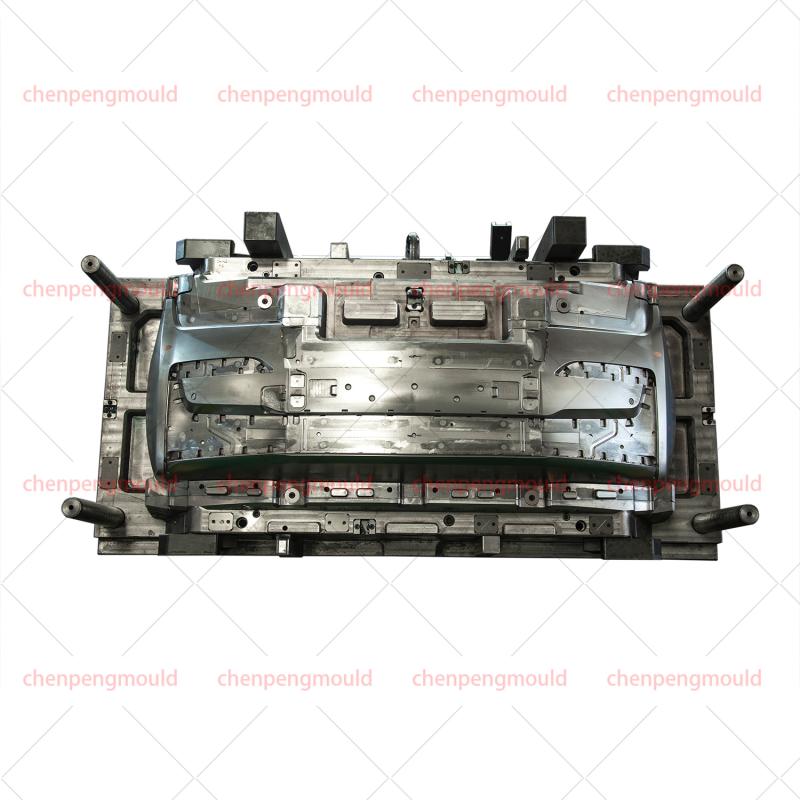

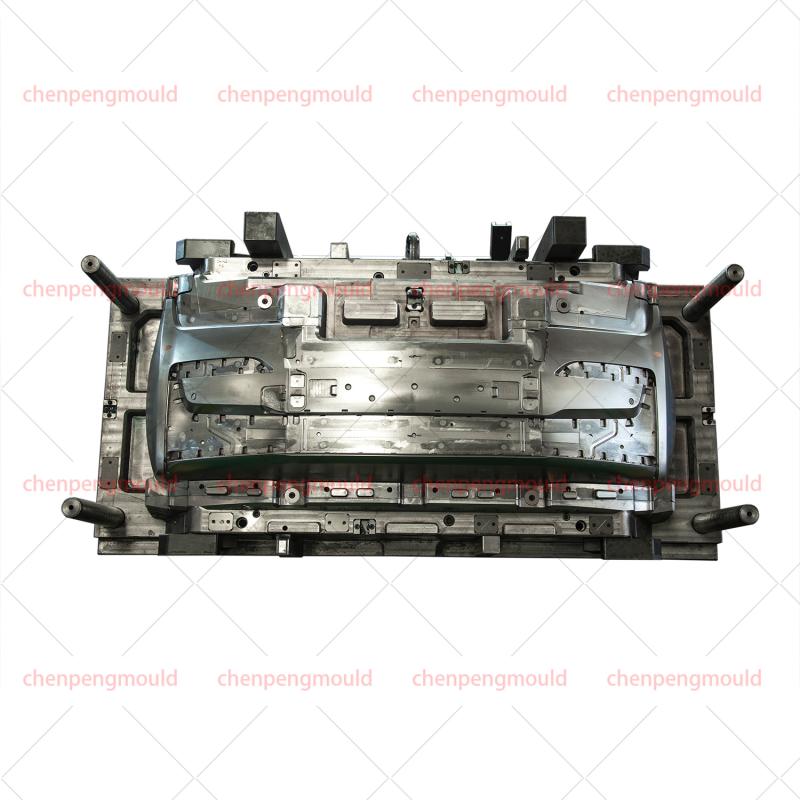

TAIZHOU HUANGYAN CHENPENG MOULD CO.,LTD

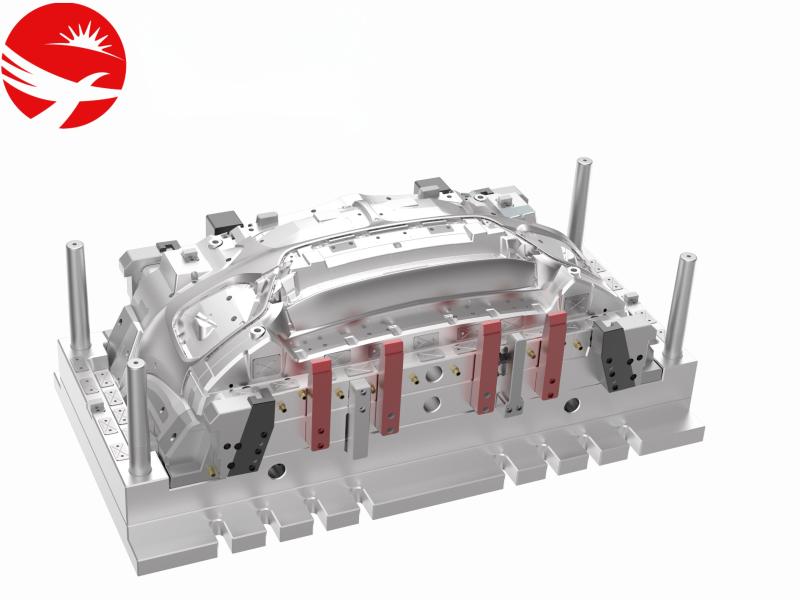

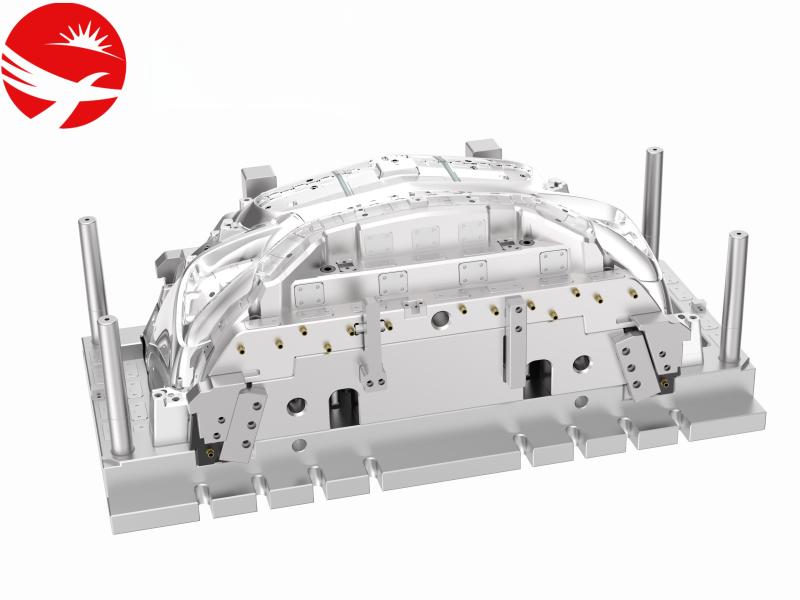

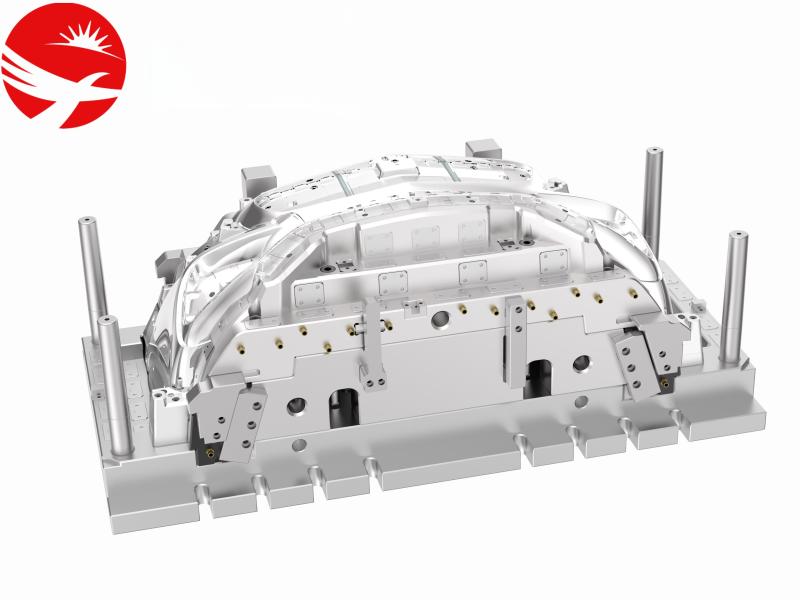

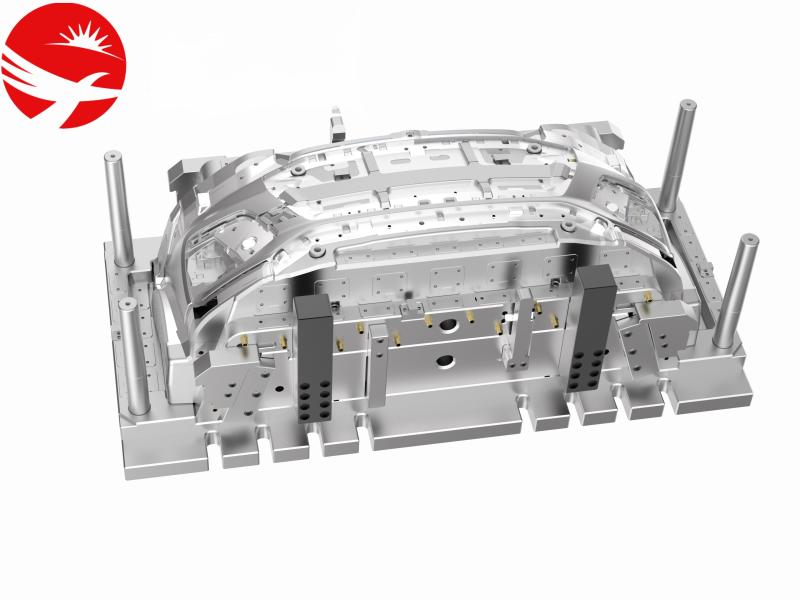

Chenpeng Mould is a professional enterprise specializing in the production of automotive injection molds. The company's main business is the development and manufacturing of automotive exterior and interior mould and modified bumper mould, with strong forward product design and development capabilities. The company has accumulated rich experience in the design and development of automotive injection moulds since 2000. The founder Mr. Yimin Jin of the company is well-known in this industry and has invented and created various structural designs of bumper moulds, leading the design of bumper mould structures in the industry.