| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

WORLDLY INDUSTRIAL CO., LTD.

No.2, 7th Road, Taichung Industrial Park / / Taichung / TAIWAN

|

Contact Info: +886 4 2359 9850 ext.

|

Hall: 10

Stand: 1015H

|

||||||||||||

| Product Groups | ||||||||||||||

|

No product group found |

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Founded with the enterprise motto『Best Quality, Active Service, Advanced Technology, Constant Innovation』, WORLDLY INDUSTRIAL CO., LTD has gone through 40 years experience in the printing professional field and become a famous brand in Taiwan printing industry. In order to provide the best solution to the progressive market, Worldly has transformed the brand position from a professional manufacturer for rotogravure printing machines, coating machines and laminating machines, to a versatile manufacturer for soft package machines at present. Until now, the entire successful outcome is result in the trust and supports from clients. Clients are the most important and supportive power to Worldly. From the stable high-speed rotogravure printing machines, laminating machines, special coating machines, extrusion laminating machines for different materials and applicable hot melt coating machines, to various film sanding machines, high speed slitting machines and reversible rewinding inspection machines, Worldly is capable of providing a complete production line as the best solution to meet diversified requirements of clients. Also, client satisfaction is always the top mission for Worldly. For fulfilling the ideal service to all clients, Worldly has been constantly researching and developing with continual production machinery expansions. Except for the devotion on equipment development, Worldly also pays much efforts on client service as the exclusive customized service. At present, this customer-oriented business mode has earned business success and solid trust from clients in 23 countries, and has lead Worldly to be the best profit consultant and good partner in printing field worldly.

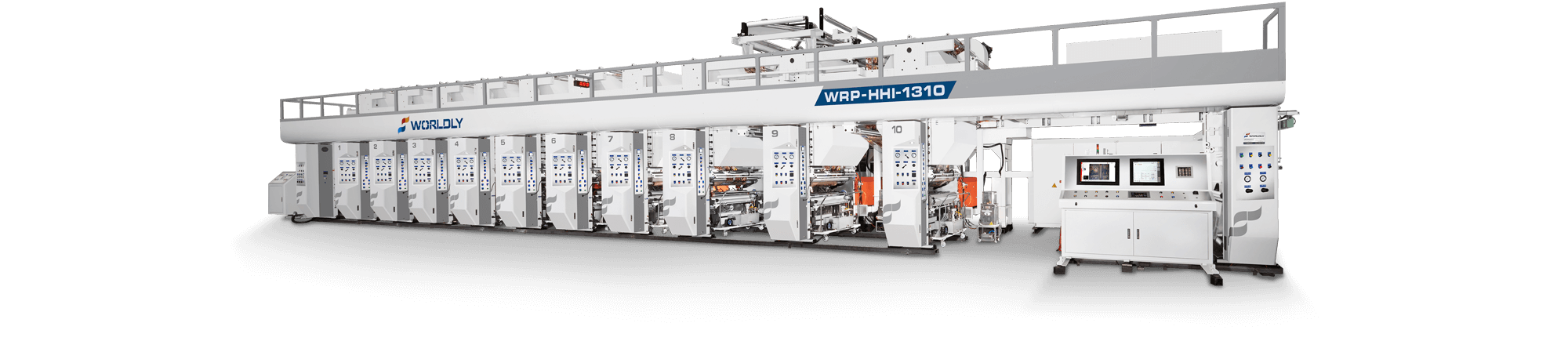

Due to the fact that the market of flexible packaging changes rapidly, most orders are of small-volume but large-variety. As a result, Worldly has prepared solutions for users: The high speed electric line shaft rotogravure printing machine, which could reach a high printing speed of 350 MPM. The shaft-less design of the ink trolley group and the changeable blade design help shorten the changeover time between orders. Besides, the printing quality is also raised due to the ink furnisher roller device in the ink trolley group. Therefore, these advantages help customers cope with the challenges of short delivery time, manpower shortage, higher cost in production, and the rigid demand of quality control management. With the heat recycling system, the energy consumption can be reduced by 30%. The automatic viscosity controller could display correlated surveillance data on the HMI (human-machine interface) for users. Moreover, the 100% inspection system can detect any miss prints, doctor blade hair line, insect, and splash spot issues instantly. The machine is equipped with the German registration and ELS sectional drive, which reduce the time for pre setting as well as the material waste, realizing accurate color registration. Worldly pays attention to every customer s demands, and customizes equipment for you based on your own specifications and the market trend.

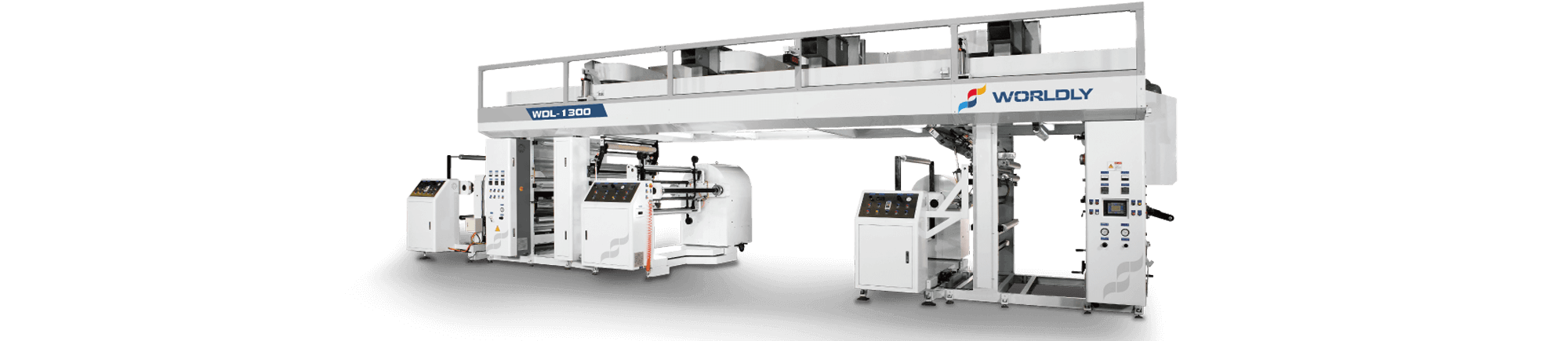

In response to the mass demand of various materials and multiple methods in flexible packing markets, WORLDLY WDL series drying laminating machineries as the ultimate solution. With this machine automatic taper tension settings can also be easily adjusted from HMI according to different technology process applications. Internal guiding rollers in the drying tunnel are connected together with belt and driven by motor. In addition, to insure smooth and solid firm laminating results. The laminating unit uses three rollers press design. The back up roller provides more even pressure to the nip roller and performs more uniform bonding effect. With these specific designs on the WDL, provided is increases production and minimize loss which are essential for flexible packaging.

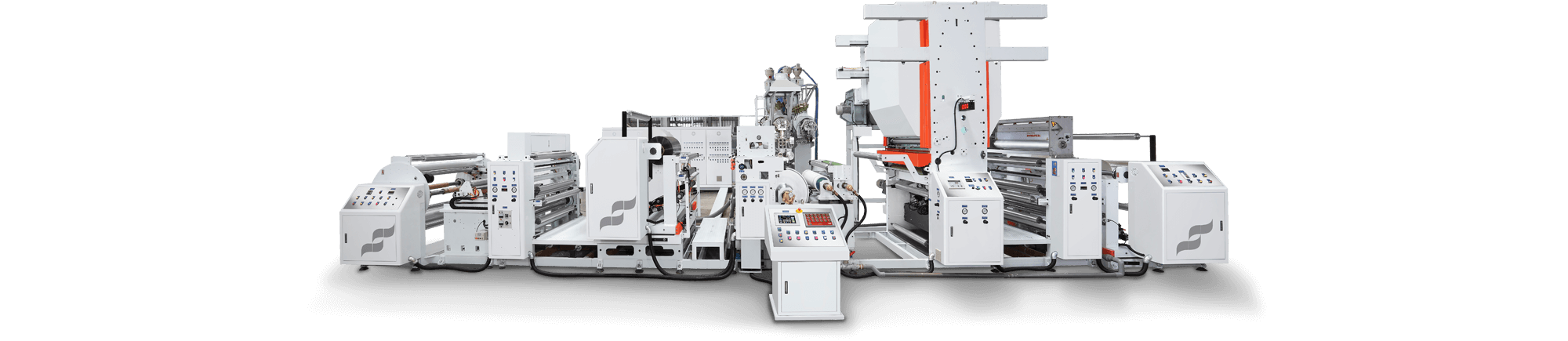

In this fast changing packaging market the multi-layer laminates demand has increased. The Co-extrusion machine allows to use two kinds resin or more by two or more extrusion units to create multi-function extrusion layers. The variety of resin after melted and go through the feed block then join into the T-die. The side screw has corrosion resistance treatment. It s fine to work with acid copolymer resin, such as EVA, EAA, EMAA and Surlyn etc. The barrel heated by ceramic heater to ensure more energy saving and short start up time. Worldly also developed the exclusive extrusion output control system with Germany leading dosing system company. So it provides very accuracy and stable output and coating gauge control during the production. It can save more material especially for long run job. The high speed H series version of the rewinding splicer adopted with tracking roller device. It provides two kinds gap & contact winding mode and gives uniform and perfectly straight finished winding during high speed running. Also the taper tension can proper control the winding from the beginning roll. So it can reduce the wastage and avoid the wrinkle generate at the inner roll.

No represented companies found.

The company has no registered brand information.

TR

TR