| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

YAPRAKSAN PLASTİK SANAYİ VE TİCARET A.Ş.

İstanbul Tuzla Org. San. Böl. 2. Cad. No: 27 Tepeören / Tuzla / İSTANBUL / TÜRKİYE

|

Contact Info: +90 216 593 1250

|

Hall: 4

Stand: 416

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Our establishment started to serve the plastics industry through its first plant with an annual capacity of 500 tons under the tradename Yapraksan Plastik Kimyevi Maddeler Ambalaj Sanayi ve Ticaret Limited Sirketi (namely Yapraksan Plastics Chemicals & Packaging Industry & Trade Ltd. Co.) in Davutpasa of Istanbul in 1996. Our journey beginning with the production of Standard Masterbatches took our company one step further, supported by the establishment of an R&D laboratory after we relocated to our factory in Dudullu. Our product line that developed with the production of specialty colors for engineering raw materials progressed with our annual capacity reaching up to 3,800 tons in line with the demands and needs of the industry. Yapraksan stepped up its machinery in 2010 in the new production area established on a 6,200-sqm area in Istanbul Tuzla Organized Industrial Zone. Having increased its annual capacity to 16.000 tons by incorporating additive masterbatches into its product line, Yapraksan continues its journey in its current plant. Our field of operation consists of 4 main groups color, black, white and additive Masterbatches. In 2016, the company had its name changed to Yapraksan Plastik Sanayi ve Ticaret Anonim Sirketi (namely Yapraksan Plastics Industry & Trade Inc.) and continued production without slowing down under the Yapraksan Masterbatch brand. With its continuous improvement approach and rising charts, the establishment became a brand that made a name for itself in Turkey and in the world. We integrate masterbatch production with the industry experience we have acquired for many years in line with our quality policy, vision and mission. Thanks to our specialized and experienced staff, we aim to be a real Solution Partner who caters for the needs of our customers through quality service and reasonable price policy. Yapraksan Masterbatch Quality Policy YAPRAKSAN, adopting a creative and dynamic understanding of working, is engaged in the plastics industry with masterbatch production along with its talented staff, robust technical infrastructure and successful financial process management. Developed in line with Customer orientation, Leadership, Employee engagement, Adoption of process approach, Management by goals and data, Supplier relationships based on mutual benefit, and Continuous improvement and innovation, the Quality Policy is intended to; to cater for any customer demands and expectations in all aspects, to carry out activities that ensure the sustained recognition of good and quality products in the domestic and foreign markets, and to be a leading company that all its employees, especially the top management, are proud to be a part of. Our mission is; To solidify Yapraksan s position in the industry by combining the best service with quality products that go well beyond the expectations of our customers and by providing fast, affordable and continuous solution

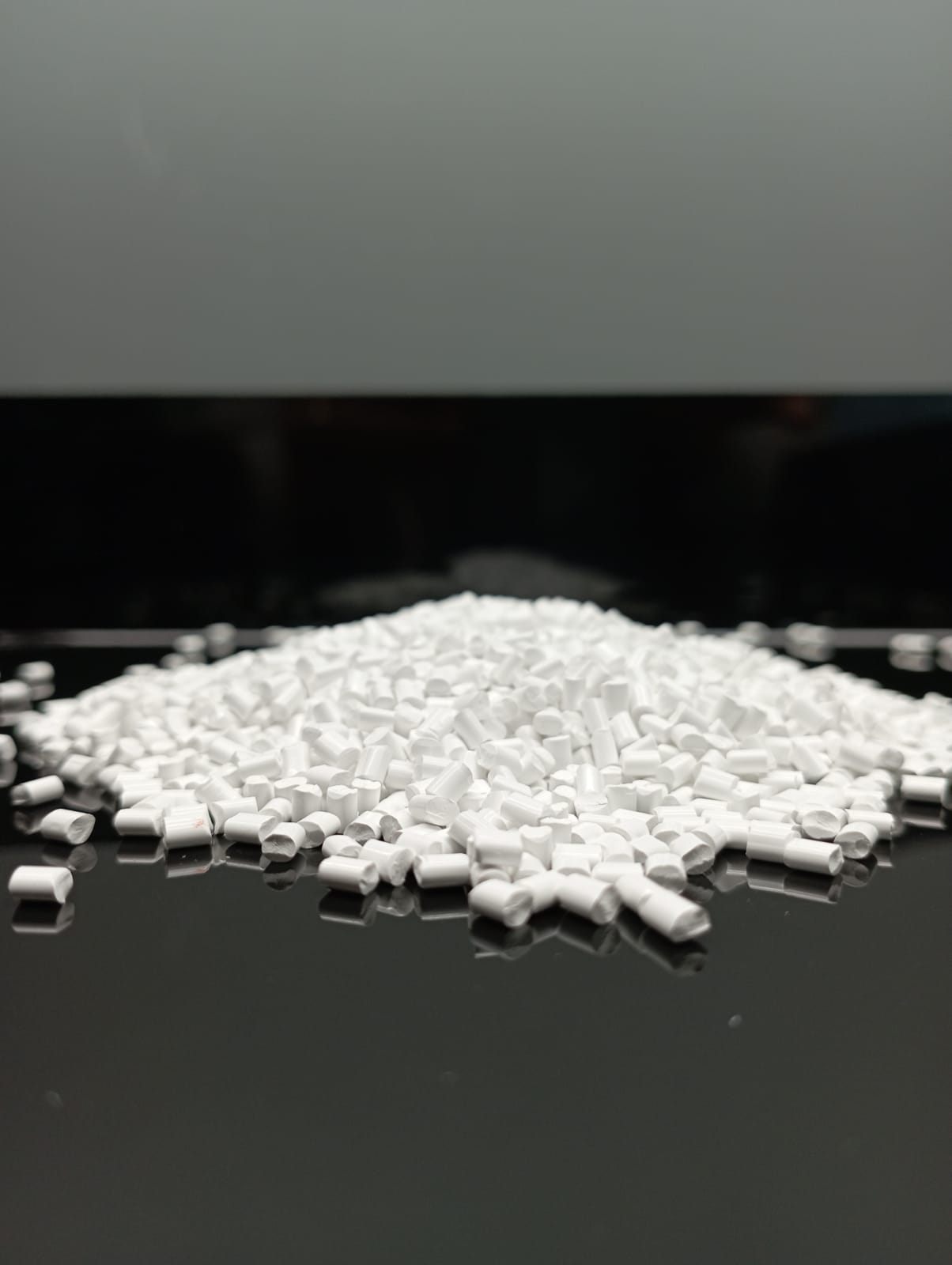

Yapraksan Masterbatch serves the Packaging, Electrical & Electronics, White Goods, Automotive, Cable, Toy, Building Materials, Medical and Compound industries through its white masterbatch products, which are produced at different Titanium Dioxide proportions and undertones, formulated at international standards considering the demands from its customers. Only high-quality Rutile Titanium Dioxide is used to produce White Masterbatch, and the product line is developed based on the application and demand. TiO2 content in our products developed under the category of engineering polymers as well as of easily processable polymers, such as Polyethylene and Polypropylene, vary between 20%-70%. We deliver a variety of solutions to our customers with our filled and unfilled options.

As Yapraksan Masterbatch, we deliver services to the plastics industry by producing Black Masterbatch that has the highest number of intended uses in the industry We have standard product lines produced in-house, which appeal to various industries. Yapraksan formulates its products, produced to suit for different applications and different product ranges, using appropriate types of Carbon Black and offers innovative solutions to its customers. Sustained quality, which is the most pivotal principle of Yapraksan family, delivers numerical values that never deviate regarding Black Masterbatch as with every masterbatch. Formulated by choosing from HAF, ISAF, P-TYPE and SRF Carbon Black types based on the final product and application, our products are mainly used in Film Applications, Electrical & Electronics, Automotive, Packaging, Cable, Toy, Building Materials, Medical and Compound industries. When choosing the products for use in Injection, Extrusion, Profile Extrusion, Sheet Extrusion, Thermoforming, Compounding, Raffia, Blow Molding and Roto-molding applications, it is advisable to choose from our products with 20% to 50% Carbon Black content considering the application areas so that the desired result can be achieved.

Our company, which has a long history in coloring works and the expertise and technical capacity required to produce precise color matches quickly, proved itself on the path of becoming a one-stop-shop business partner where you can meet your needs through detailed coloring works it has been carrying out for many years. When getting prepared for coloring works, we adopt a coordinated approach to offer creative solutions that cater for your functionality and harmony needs. After establishing cooperation with the companies we work with in all relevant industries, we engage in discussions with in-house business development departments. This coordinated approach allows us to understand our customers technology, needs and product lines. With the ideas we exchange mutually in masterbatch production, we do not only offer our customers the most affordable and optimal solution, but also enjoy pushing our limits. Along with standard colors, we produce fast and effective solutions with our special coloring works that will meet your demands exactly. We carry out special coloring works based on international catalogs [Ral, Pantone etc.], finished product pieces or masterbatch samples. Our company, adopting the principle of supporting our customers by fast sample deliveries, will continue to cater for your demands through the understanding of the infinity of colors.

Additive masterbatches, which the finished product characteristic features or facilitate its processing, take your product one step further and make it functional. In addition to the visual properties that other masterbatches add to the product, the additive masterbatches used do not only make the plastic look visually appealing, but also help it become functional. Additive masterbatches have no impact on the color of the product, and they sometimes form a layer on the surface of the polymer depending on the additive type and sometimes function in line with the intended use. Additive masterbatches, which can be used in each of the Extrusion, Injection, Film, Roto molding and Blowing processes, are advancing gradually with the progress of the plastics industry and plastics technology. New products are presented to the plastics industry in line with the demand.

No represented companies found.

The company has no registered brand information.

TR

TR