| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

AKDENİZ CHEMSON KİMYA SANAYİ VE TİCARET A.Ş.

Kemalpaşa OSB Mah. İzmir-Kemalpaşa Asfaltı Cad. No: 45 / Kemalpaşa / İZMİR / TÜRKİYE

|

Contact Info: +90 232 877 0144

|

Hall: 3

Stand: 319

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

A world leader in PVC stabilizers, Akdeniz Chemson was formed out of the merger of Akdeniz Kimya and the Chemson Group. Who We Are? Our story began in 1942 Cookson from Wallsend near Newcastle-upon-Tyne in England starts producing lead salts as stabilisers for flexible PVC. Shortly after, Cookson opens a production plant in Sydney/Australia. In 1976, when Akdeniz Kimya was incorporated in İzmir, Turkey as a company to manufacture and market PVC stabilizers and other industrial chemicals. In 1986, the German stabiliser manufacturers Chemetall and the English Cookson Group merged their activities into a single joint venture as Chemson with headquarters in Frankfurt am Main, Germany. The company began operating from sites in Germany, England and Australia. In 2000 Chemson Polymer-Additive AG is founded in Arnoldstein/Austria as a part of a management buy-out. In 2012, Akdeniz Kimya joined Turkey s OYAK Group of companies. One-year later, the Chemson Group became part of the OYAK Group as well. With its robust corporate structure, its dedication to transparency, its strong financial infrastructure and growth commitment in chemistry, OYAK supported both companies to develop and produce innovative solutions. In September 2020, these two strong brands merged into Akdeniz Chemson, one of the leading producers of polymer additives, and the world market leader in the field of PVC stabilizer products. Focused on quality, innovation and sustainability, the company works as a one-stop-shop for clients around the world, in order to supply all their needs in formulation.

No product info found.

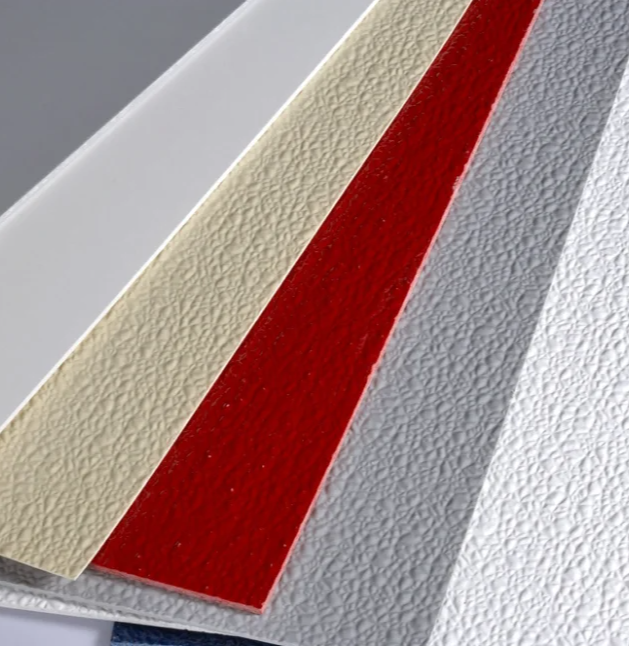

Metal soaps that result from the reaction of a metal oxide or a metal hydroxide with a fatty acid are used as co-stabilizers and internal/external lubricants in PVC formulations. Metallic soaps (AKSTAB®, LISTAB®) can be used in PVC formulations either individually or in synergistic combinations (Ca/Zn, Ba/Zn, etc.). In general, they are the compounds formed by the fatty acids of various lengths (C8 C22, etc.) together with metals. Commonly used types are the Al, Ba, Ca, Pb, Mg or Zn soaps of stearic, lauric or benzoic acids. Calcium stearate, barium stearate, and the laurates of these metals, which are used as internal lubricants in PVC formulations, also act as co-stabilizers that increase the heat stability, revealing their effects through the formation of the CaCl2 salt, which is produced as a result of their reaction with HCl that is released from the thermal degradation of PVC structure. Among the metal soaps of the zinc that are used as external lubricants in PVC formulations, zinc stearate and zinc laurate also have the reducing effect on the initial colouring. They act as co-stabilizers in the process, revealing their effects through the formation of the ZnCl2 salt, which is produced as a result of their reaction with HCl that is released from the thermal degradation of the PVC structure.

Hydrotalcite is a white mineral having a layered structure found in nature with a general chemical formula of Mg6Al2(OH)16CO3.4H2O. PVC is decomposed during processing from heat and the shear stress effects and is decomposed by the effect of UV rays while it is in final product form, resulting in the Cl in its structure being released. Cl, which is released into the medium in the form of an HCl gas, may cause the PVC first to turn yellow and then to burn out. The most important functions expected out of the stabilizers is to chemically react with the HCl which has been released. Hydrotalcites are very effective in PVC stabilization because they are very good acid scavengers due to their exceptional anion-exchange properties. Hydrotalcites have greatly enhanced the performance of Ca/Zn-based stabilizer systems, due to their features of environmentally friendliness and non-toxicity. They particularly have a major share in the development of stabilizers used in the production of rigid PVC window profiles and flexible PVC automotive cables with high service temperatures. At Akdeniz Chemson, we have 2 types of hydrotalcite products. -AS-01 (Magnesium Aluminium Hydroxycarbonate Hydrate) -AS-04 (Magnesium Zinc Aluminium Hydroxycarbonate Hydrate)

Lubricants (AKLUB®, NAFTOLUBE®) are very important for PVC processing due to their properties to facilitate the process by means of reducing friction. For example, rigid PVC processing is impossible without lubricants. Typical lubricants belong to the following chemical families; hydrocarbon waxes, metal stearates, fatty acid esters, ester waxes and amide waxes. Lubricants can be classified into three main sub-groups as external, internal and combined lubricants. This grouping is according to their lubrication and are called combined lubricants.

DMA 650 provides homogeneous melt flow at different production rates in addition to providing high impact resistance and mechanical properties in PVC applications. Enhanced powder properties bring advantages in packaging and handling. Thanks to its special design, DMA 650, with its easy-flow, low dust and odour characteristics, can be used with automatic handling and feeding systems, for quicker and safer working operations. Akdeniz DMA 650 enables manufacturers to produce high quality complex PVC products even at high production rates. Having long-lasting UV resistance and excellent colour stability and durability, DMA 650 ensures that PVC products can retain original appearance during long-term outdoor exposures and under adverse weathering conditions. In addition to its unaccompanied use in formulations, DMA 650 can offer more economical solution to our producers, thanks to the many years of experience of Akdeniz Kimya has in PVC stabilizers area, by means of reducing the use of Impact Modifier (DMA 650) in its formulation. DMA 707 is an intelligent and synergistic combination of the Acrylic Based Impact Modifier (DMA 650) with CPE. The premix of DMA 650 and CPE has advantages in comparison to the use of the two single modifiers; Improved impact strength Lowered plate-out Procurement of the product from one supplier instead of two. Cost saving regarding storage, dosage at hot mixer

Acrylic processing aids are included in the group of polymer additives which facilitate and regulate the melt flow in thermoplastic productions, with their low utilization rates. Acrylic processing aids are included in the group of polymer additives which facilitate and regulate the melt flow in thermoplastic productions, with their low utilization rates. Rigid PVC applications have made significant progress since 1950, (the date when processing aids began to be used). PVC, which has low heat and light resistance, overcomes its brittle, fragile structure only with the support of processing aids.

Benzoate type plasticizers are non-phthalic, environmentally friendly plasticizers used in applications such as polyurethane, PVC, adhesives, filling compounds, acrylic, PVA, and SBR. They are used instead of the traditional phthalate-based plasticizers. Benzoate type plasticizers act as processing aids during the processing of the polymer, helping to reduce fusion temperatures, thus leading to lower energy consumption.

Zinc Phosphate (ZNP 50) Zinc Phosphate ZNP 50, which is used especially in paints applied on metals, is one of the innovative and most important anti-corrosive pigments. Zinc Phosphate ZNP 50 can be used in both solvent-based and water-based systems, with its excellent dispersibility and high compatibility. with its excellent dispersibility and high compatibility. In addition to its anticorrosive properties, it also enhances the surface adhesion ability of the paint, extends the life of steel & metal surfaces and reduces costs for long term use. Apart from being a good alternative to chromium-based anticorrosive pigments, zinc phosphate is also more compatible with the environment and human health. Zinc phosphate-containing paints are used in many industrial areas that require high corrosion resistance such as the construction, industrial infrastructures, automotive, aerospace and marine sectors. Akdeniz Chemson s globally extended network provides customers zinc phosphate with the opportunity of fast delivery & local technical service.

Zinc Borate (ZNB-35) ZNB-35 upgrades the thermal stability and UV stabilization of the flame retardant in polymer formulations and acts as a great smoke suppressant by promoting char formation. Thanks to its high dehydration temperature, it is used in production of high temperature resistant polymers. It can be used in both halogen-containing and halogen-free flame retardant formulations. Melamine Cyanurate (MCN) In the last decades, high demands in fire safety have increased the consumption of flame retardant polymers. Not only the reaction to fire, but the reaction to the environment of flame-retarded systems have become key issues. MCN is a halogen-free flame retardant, which meets the requirements of environmental protection and is mainly used for PA6 and PA66 to achieve UL 94 V-0. Above 320°C, it undergoes endothermic decomposition and the vaporized melamine acts as an inert gas source diluting the oxygen and the fuel gases present at the point of combustion. It shows excellent flame retardant properties and compared with APP & MPP, have better compatibility with most carriers. MCN is a colorless, odorless, non-toxic white crystalline powder and it is nearly insoluble in water, and soluble in ethanol, methanol and other organic solvents. Characteristics; Halogen-free, lower smoke density, low smoke toxicity and less corrosion Better electrical and mechanical properties Good thermal stability Environmentally friendly Excellent dispersibility

No represented companies found.

The company has no registered brand information.

TR

TR