| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

ALARGE ALIÇ AĞACI MAK. ELEK. ARAŞ. GELİŞ. SAN. TİC. LTD. ŞTİ.

Çiftehavuzlar Mahallesİ Eski Londra Asfaltı Caddesi Yıldız Teknik Üniversitesi Davutpaşa Teknopark D2 Blok No: 2B01 / Esenler / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 924 5652

|

Hall: 5

Stand: 509B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Alarge was founded in 1997 by Prof. Dr. Ahmet Koyun, who is currently working as a lecturer at Yildiz Technical University Mechatronics Engineering. It is a research and development company that has been designing and producing high quality and advanced technology domestic laboratory test devices based on mechatronics-based scientific research by combining machinery, electrical-electronics and software from engineering branches with the title of R&D Center in Yildiz Technical University Technopark since 2014. Alarge has proven itself by working with more than a thousand local customers since the day it was founded, with its engineers who are experts in their fields, doing masters and doctoral degrees. Globally, test institutes in 18 different countries offer innovative approaches to the test laboratories of pipe production, recycling and plastics companies, produce solutions that meet the needs of companies and provide reliable test devices.

Hydrostatic pressure testing is a testing method used to evaluate the durability, tightness and performance of an object. This test is done by applying water or other fluid pressure to an object. During testing, pressurized liquid is pumped into the object and kept under pressure for a certain period of time. During this time, the object is examined against specific criteria to evaluate its durability, deformation, sealing, or other performance characteristics. The hydrostatic pressure tester is equipment specifically designed to perform this test. These devices include a pump system that pumps pressurized fluid into the object, pressure gauges, and often a valve system that controls the pressure exerted on the object under test. Also available for sealing tests may be measuring instruments that monitor pressure drop to detect leaks. Hydrostatic pressure testing of pipes is a widely used practice to evaluate the durability and tightness of pipelines. Hydrostatic pressure testing can be applied to pipelines when a new pipeline is constructed or when an existing line is maintained or repaired. This test is an important method to check the tightness of pipelines, detect unwanted leaks, determine whether pipelines can withstand a certain pressure, and verify that they can be used safely.

It is a water-filled volumetric structure in which the water environment required for hydrostatic pressure testing is provided and the test is carried out. Water distribution and circulation of water in the tank are kept within a certain temperature range. Circulation heating or cooling is used to keep the temperature constant. The location of the heaters and the locations of the fluid taken for water circulation in the tank and returned to the tank were designed by simulating the experimental data of the real tank in a computer environment and the results were approved by EU accreditation. Suitable for PPRC, PPH, PPB, PE, PVC, PE-RT pipes and even composite pipes.

End caps are generally produced in accordance with the diameter of cylindrical objects (pipe) and are designed to fit tightly onto the ends of the pipe. These hoods are mostly made of durable materials and must be pressure resistant. Different types of designs are available so that the capping caps can be conveniently attached to the pipe ends. In each of the different types of designs, the head is placed tightly on the pipe end and a seal is ensured. These headers ensure that the pressurized liquid remains in the pipe, prevent leaks during the test and create a safe test environment.

Tensile test, compression test and ring stiffness test, creep test and fatigue test are common test methods used to evaluate the mechanical properties of materials and structures. These tests are performed to determine the durability, stress and deformation behavior of the materials and to verify the suitability of the materials used in the design process. Tensile testing is a testing method applied to determine the tensile strength and elastic behavior of a material. In this test, while a sample is stretched at a certain speed, the force applied to it and the amount of extension of the sample are recorded. Using these data, a stress-strain curve is created and important properties such as the elastic region of the material, maximum tensile strength and breaking point can be determined. Tensile testing is often used to determine the strength properties of metal, plastic, elastomer and composite materials. Compression testing is a testing method used to evaluate the compressive strength and behavior of a material. In this test, while a sample is pressed at a certain speed, the force applied to it and the amount of compression of the sample are recorded. With the compression test, properties such as the compression strength, elastic region and compression modulus of the material are determined. Compression testing is commonly used in the strength analysis of materials such as plastic, cardboard, composite ceramics and concrete. Ring stiffness test is a testing method used to measure the stiffness of a tubular structure. In this test, compressive force is applied to the annular pipe sample and a specially named compression test is performed. Universal testing machine is used to evaluate the strength properties and behavior of materials. It has the ability to apply various test methods such as tensile test and compression test. This device is used to determine the elastic properties of materials, stress-strain relationship, breaking point, elastic limits, tensile strength, compressive strength, bending strength and other important mechanical properties. The universal testing machine measures the response of the material by applying a controlled load or moment on the samples. This testing machine is designed to understand how the sample behaves under various loading conditions such as tension, compression, bending, torsion and compression. The data obtained during testing is used in many areas such as material strength and durability evaluations, product development process, quality control and engineering design.

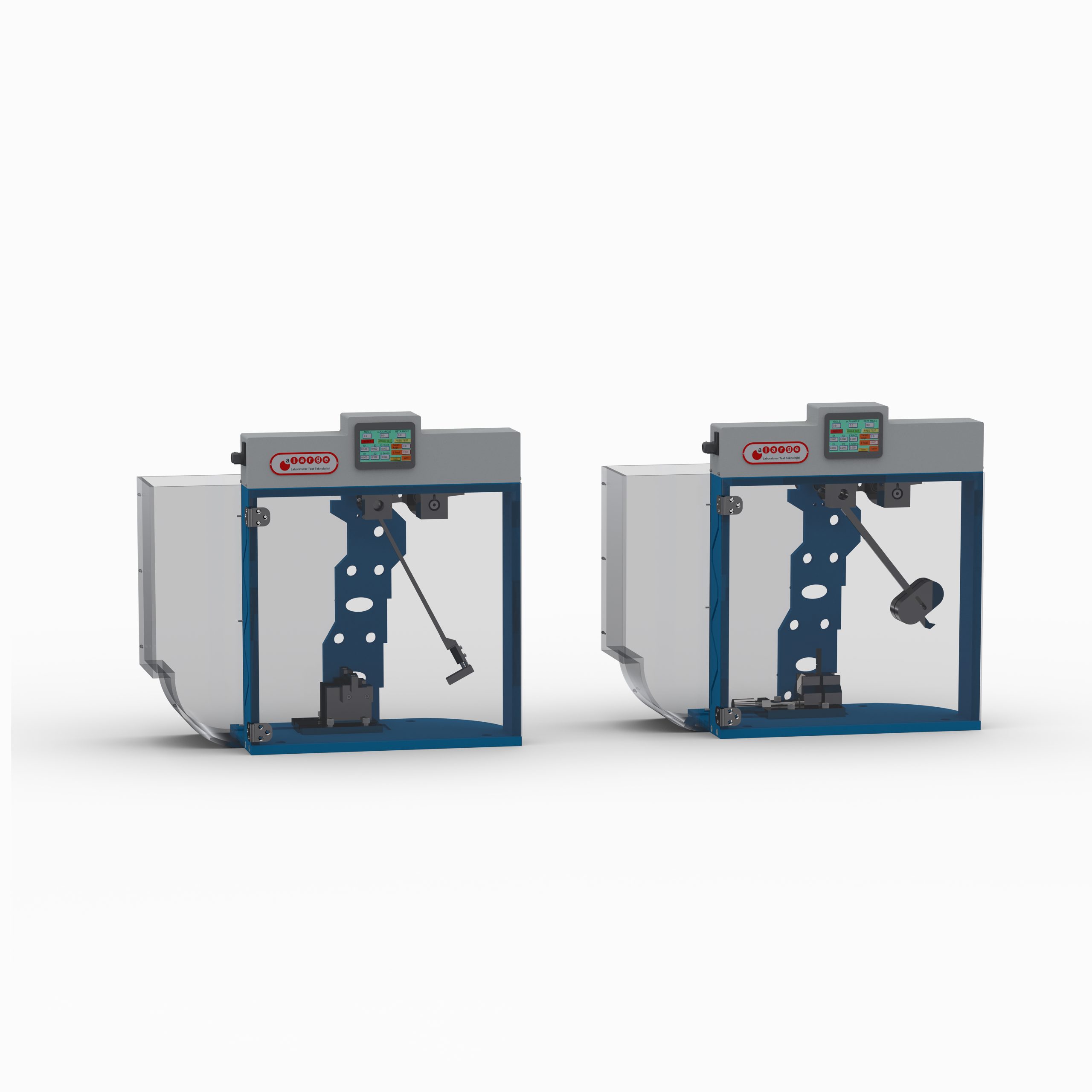

Pendulum impact (charpy & izod) test is a testing method used to evaluate the impact durability of materials. This test is generally performed to determine the fracture behavior of materials such as metal and plastic. The pendulum, released at a certain speed, impacts the test sample and the fracture energy of the sample is measured. The pendulum impact tester is a special device designed to perform this test. This device has a mechanism that can control and measure the impact energy of a pendulum. The pendulum, which usually has a weight, is released from a certain height and applies an impact to the test sample. The pendulum impact test device is used for purposes such as evaluating the impact resistance of materials, making improvements in design and production processes, deciding on material selection, and checking compliance with standards. This testing is an important tool for understanding how materials will behave under real use conditions. Impact test results provide important data used to evaluate the durability, fracture resistance, and fracture mode of materials.

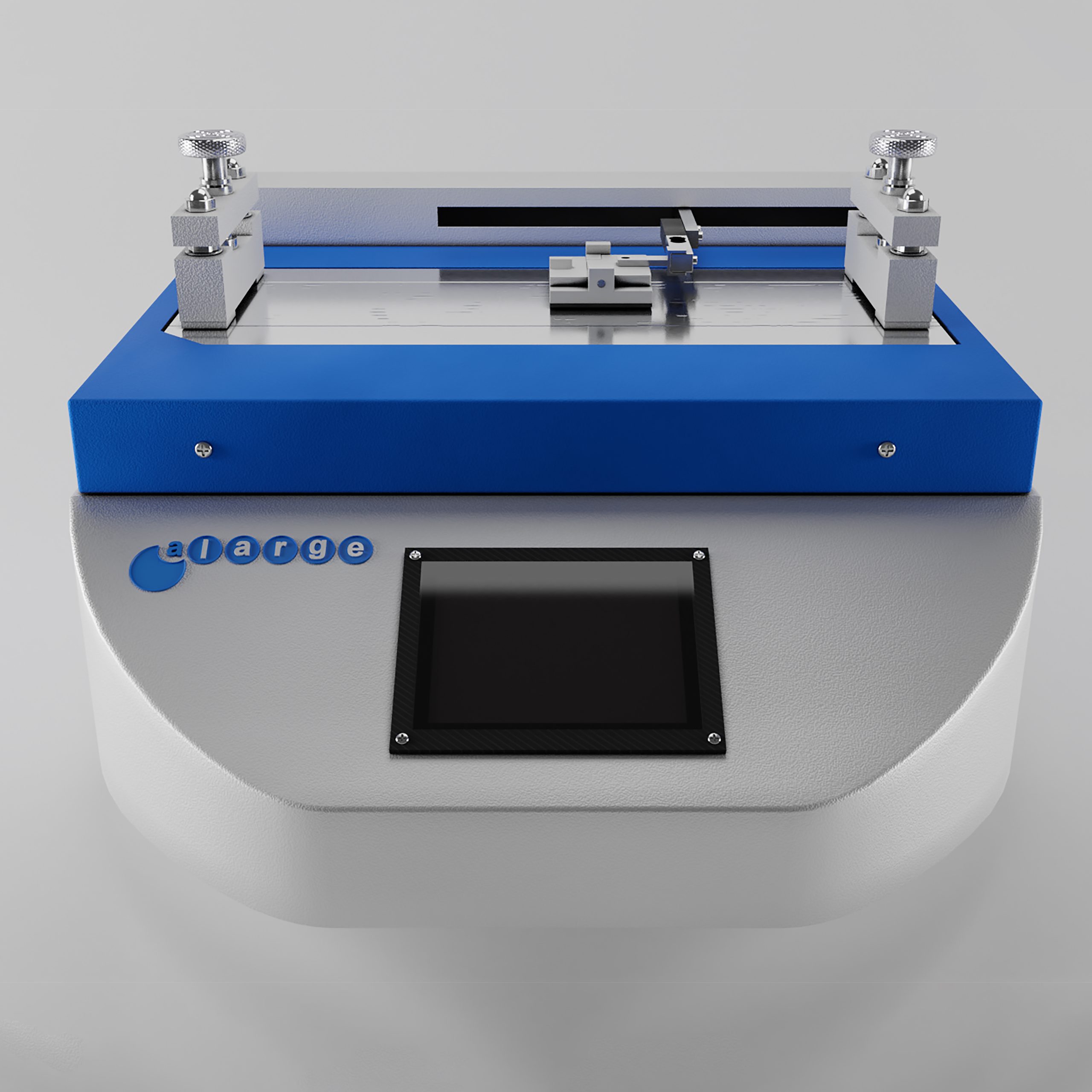

Coefficient of friction testing is a testing method used to evaluate the friction behavior of a material. This test measures how the surface of the material affects the friction force when in contact with another surface. The coefficient of friction defines the frictional resistance of two surfaces against each other. The coefficient of friction testing is a measurement tool used to perform this test. These devices generally include a sample surface and a pushing or pulling mechanism. Frictional force is measured as a result of force or motion applied to the sample surface. These devices are used to compare and optimize the friction performance of different materials or coatings. Coefficient of friction testing machines are designed and manufactured in accordance with national and international standards. These standards specify testing conditions, sample preparation guidelines, and accepted procedures for evaluating results. In this way, test results performed in different laboratories can be compared and reliable results can be obtained.

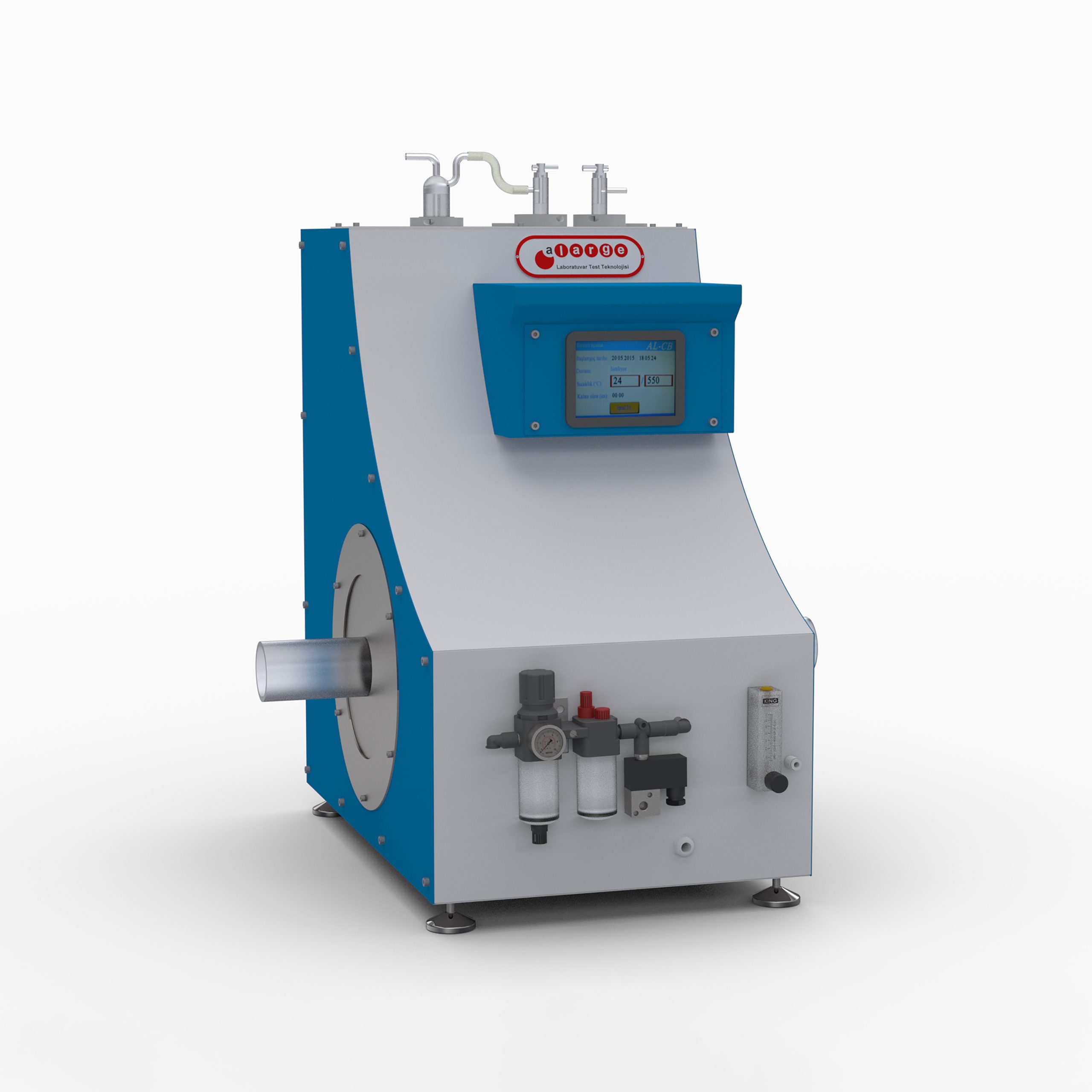

Melt flow indexer (MFI) is a testing method used to measure the flow properties of polymers. This method allows the polymer to flow at its melting point under a certain temperature and a certain load. The melt flow index value gives information about the viscosity and fluidity of the polymer. The melt flow indexer (MFI) device measures the flow rate of polymer at a specific temperature and under load. It is often used in the plastic industry. It is used to determine the fluidity properties of the polymer, ensure quality control and compare material properties. The use of this device plays an important role in the production process of the polymer and the quality control of the products. It can also be used to compare and analyze different polymer types and polymer blends. Melt flow rate (MFR) is a value obtained as a result of the test. MFR refers to the amount of molten mass of the polymer passing per unit time at a certain temperature and under a certain load. It is usually measured in grams per minute (g/10 min). Melt Volume Flow Rate (MVR) works on a similar principle, but it expresses the amount of melted volume of the polymer passing through per unit time. MVR is usually measured in cubic centimeters per ten-minute (cm³/10 min). When the calculated MFR value is compared to the MVR value, the density of the material used in the experiment at the test temperature is found. Both values are used to determine the flow properties of the polymer and to make comparisons between different polymer types. These values are important to ensure polymer processability, quality control and managing production processes.

Oxidation induction time determination (DSC-OIT) is a device used to measure oxidation induction time using the differential scanning calorimetry (DSC) technique, which is one of the thermal analysis methods. The DSC-OIT instrument is designed to determine the oxidation stability of materials, for example thermoplastic polymers. Oxidation induction time is a measure of how thermally resistant a material is and how resistant it is to oxidation. This period refers to the time required for oxidation reactions to begin when the material is exposed to a high temperature. The DSC-OIT device is used in many applications, for example to evaluate the oxidation stability of polymers, understand the aging process, predict the performance of materials or determine product quality. This device provides the user with data to analyze the oxidation behavior of materials and determine how thermally stable they are. This information can help determine factors such as material selection, storage conditions and processing methods.

Carbon black determination is the process of determining the amount of carbon black in materials. Carbon black is carbon in a form with a high carbon content and is commonly used in the rubber, plastics, ink, paint, casting and chemical industries. Carbon black gives black color to materials and affects their mechanical, electrical and optical properties. Carbon black can be an important parameter in industrial and environmental analyses. Carbon black determination devices are widely used in material characterization and quality control processes. For example, accurate determination of the amount of carbon black during tire production is important to ensure that quality standards are met regarding carbon black content, which can affect the physical properties and performance of the product. Additionally, analyzing the distribution and dispersion of carbon black in materials can also be useful in optimizing material processing methods. Carbon black determination can be carried out using many different devices and methods. Carbon black determination equipment is often used in various industries and research fields. Determining the amount of carbon black formed during combustion processes is important for emission control and air quality assessment. It can also be used in quality control and material characterization of organic substances. Carbon black determination in the polymer pipe industry is done to determine the carbon black content in the materials used in the production of polymer pipes. Carbon black is used to improve the mechanical properties of polymer pipes, to provide protection against UV rays and to give color. However, accurate determination of carbon black content is a factor affecting the quality of polymer pipes. Determination of carbon black allows polymer pipe manufacturers to control the amount and homogeneous distribution of carbon black. This determination aims to ensure that the correct amount of carbon black is used in the production process, ensuring consistency of material properties and ensuring that products meet quality standards. Moreover, analyzing the amount and distribution of carbon black also helps in evaluating the mechanical strength, UV resistance and other performance properties of polymer pipes.

Vicat softening temperature test is one of the test methods used to evaluate the thermal properties of a material. This test provides an important parameter to determine the softening behavior of polymers and evaluate their heat resistance. Vicat softening temperature is an important parameter that shows how thermally resistant a material is and at what temperature it will change shape. Vicat softening temperature tester is a laboratory device used to determine the softening temperature of materials (usually polymers). This tester uses standard method to evaluate the softening behavior and thermal stability of the material. In the polymer pipe industry, the Vicat softening temperature test is widely used to determine the thermal performance of polymeric pipe materials. This test is performed to determine the maximum temperature limit at which polymer pipes can be used without deformation under a certain temperature. In cases where polymer pipes are used in industrial applications, the temperature resistance of the pipe is of great importance. Vicat softening temperature testing provides a standard method to evaluate the usability and performance of polymer pipe materials under a specified temperature.

No represented companies found.

- ALARGE

TR

TR