| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

ALTECH MAKİNE SAN. VE TİC. A.Ş.

AKÇABURGAZ MAHALLESİ 3137 SOKAK NO: 22/1 / ESENYURT / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 505 2273

|

Hall: 7

Stand: 706B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Altech Machinery, which started to manufacture various machines in 1974 and to produce plastic recycling machines in the following years, expanded its new storage areas of 3500 square meters in 1986 and started to export various kinds of exports. We continue to work with all our strength to protect natural resources and reintroduce them to the economy. As Altech Machinery, we realize our productions with the awareness that we have to pay for the construction of a more livable world. We have the ability to do the technological shaping on time, to include the manufacturing process quickly, and to keep the modern production way dynamic at all times. Altech Machinery, which makes plastic recycling machine lines and plastic melt filter systems; with the aim of becoming a echol; strives to be a company that is primarily preferred in the country and abroad. As Altech Machinery, we combine our priority targets and strategies with our principle of production in the longest time from quality and on time delivery. We continue our production with the principle of quality in production, technical support before and after sales, the principle of customer satisfaction, and the passion to always do the best and achieve, therefore, we are proud of the maintenance and service that we have given you for years. Thanks to our power of inspiration and desire to succeed in order to develop more innovative and stronger recycling technologies, we continue our productions with the effort to keep every promise for our present and future.

RGT w Model Plastic Recycling Machines, by crushing, mixing, heating, densifying, drying and feeding. It ensures high performance with low energy consumption. Along with special screw design,degassing system, granule cutting system, it displays high performance with best quality granules. RGT WModel is applicable to non printed and low printed products. It is modelled as being suitable for customer needs.

RGT TW Series Recycling Machines, double degassing phase, distinctive vacuum system, with more printed or high humidity metarials, outcome oriented model RGT TW Series Recycling Machine Model: Mixing, Crushing, Densifying, Feeding and Heating Operations are carried out one shot. RGT TW Model with doubledegassing, special screw design, vacuum system, recycling more printed and wetter products, it ensures brighter granules. Automation group of the system, the extruder that ensures molten plastic particles, filter group, with the granulator, the superiority of the centrifuge design and technology, high capacity, low enery consumption so that granules in perfect design and quality are ensured.

First Extruder with the cutting compactor prepares the materials for filtration after degassing of melt. After filtration there is also special degassing unit. The melt is feeded as closed system to the Tandem Extruder. Third degassing is executed on Tandem Extruder. Tandem Model is used for heavy printed materials, mixed coloured materials or materials with heavy humidity levels. Tandem Model ensures high quality granules without any gas or humidity and provides brighter granules.

The interconnected model Shredder with Extruder that the materials feeded first into shredder and then to Recycling line. For materials like PP big-bag sacks, polyster, PP yarn and hard, rigid plastics, which must be shredded into small pieces at the beginning. The materails are cutted to certain dimensions with a shredder and in the cutter compactor is densifying, extruding and granulating. Shredder and extruder work synchronously by transferring information with each other.

Plastic Products are fed to the main Screw by pushing thanks to another screw. According to customers capacity and needs, it suggests model alternatives from 300kg/h to 2000kg/h. RGT SF Series; crushed and subject to particular dimensions, plastic products are side- fed to the extruder through screw.Main extruder and feed screw belong to Altech design.That is designed as reaching perfect capacities and ensuring super plastification. RGT SF Series shows high performance for crushed, rigid scrap products .It has single degassing unit and has powerful vacuum system so that it sorts out gas particles and finally ensures bright plastificated granules.

For polyester textile waste and pet scrap products, the crystallization and feeding is completed in the compactor, provides plastification in the extruder and granulates with strand pelletizing or underwater systems. RPET Series, which provides drying and crystallization in the recycling process in the compactor, bypassing the moisture on the existing product without exposing it to humidification, granulating with a min IV decrease.

Paper, rubber, wood, unmelted plastic etc. Unwanted foreign particles such as, with the awareness of its technology, are automatically separated from the plastic without human touch, and their contamination is discharged. With its high contamination output and low melt loss, the recycling industry provides incredible convenience and profit to manufacturers. In manual filter systems; In the filtration of industrial paper waste plastics, filter screen changes between 3-5 minutes, with laser disc filter without screen replacement up to 1 week; It provides an excellent performance that allows the extruder to reach maximum capacities. Altech Microfilt Filter, designed to be easily connected to all kinds of recycling extruders; It offers models to suit the capacities of customers.

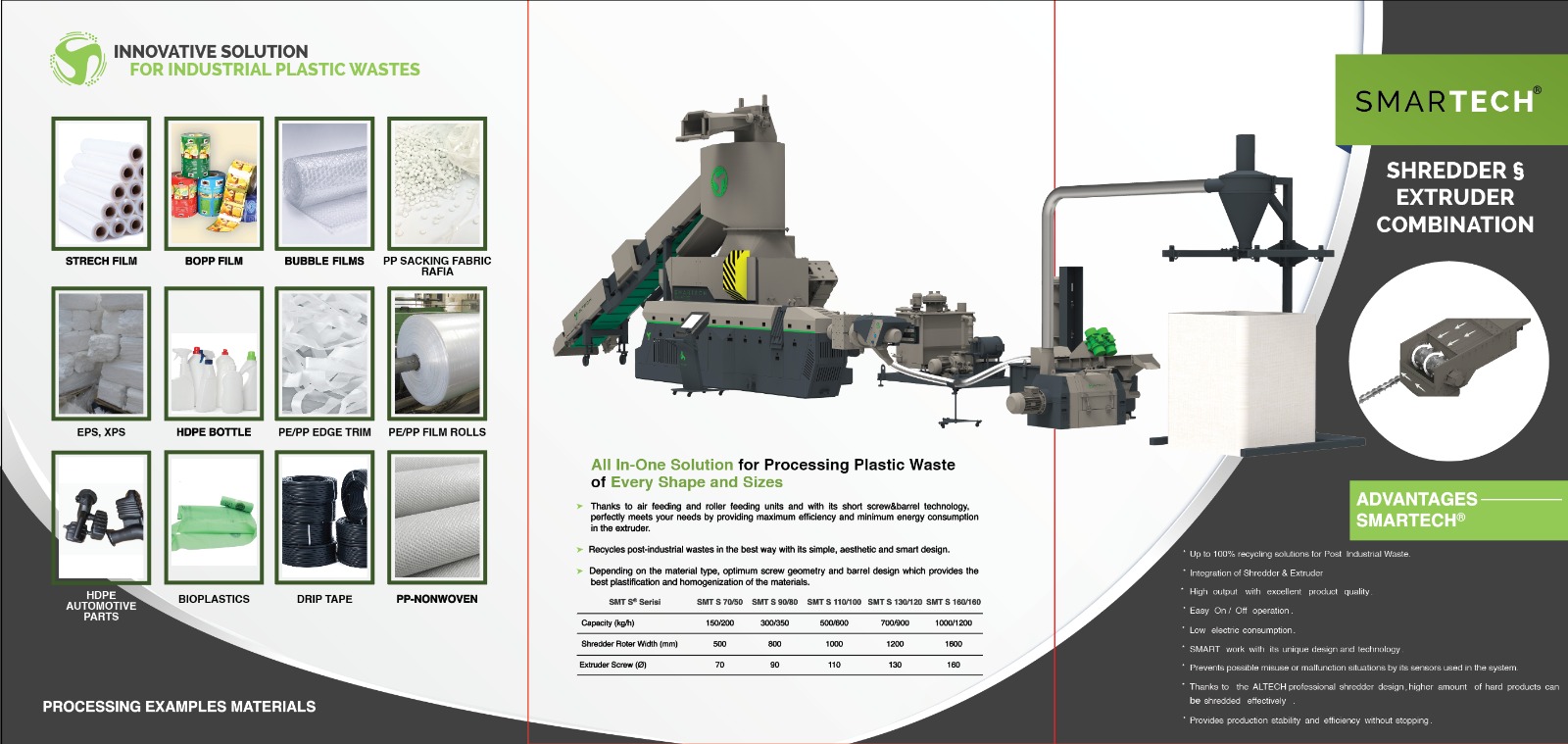

Post-Industrial Waste Solutions with SMARTECH. Thanks to its air feeding and roll feeding units and short screw & barrel technology, it meets your needs perfectly by providing maximum efficiency and minimum energy consumption in the extruder. It recycles post-industrial waste in the best way with its simple, aesthetic and smart design. Depending on the material type, it has optimum screw geometry and barrel design that ensures the best plasticization and homogenization of the materials.

No represented companies found.

The company has no registered brand information.

TR

TR