| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

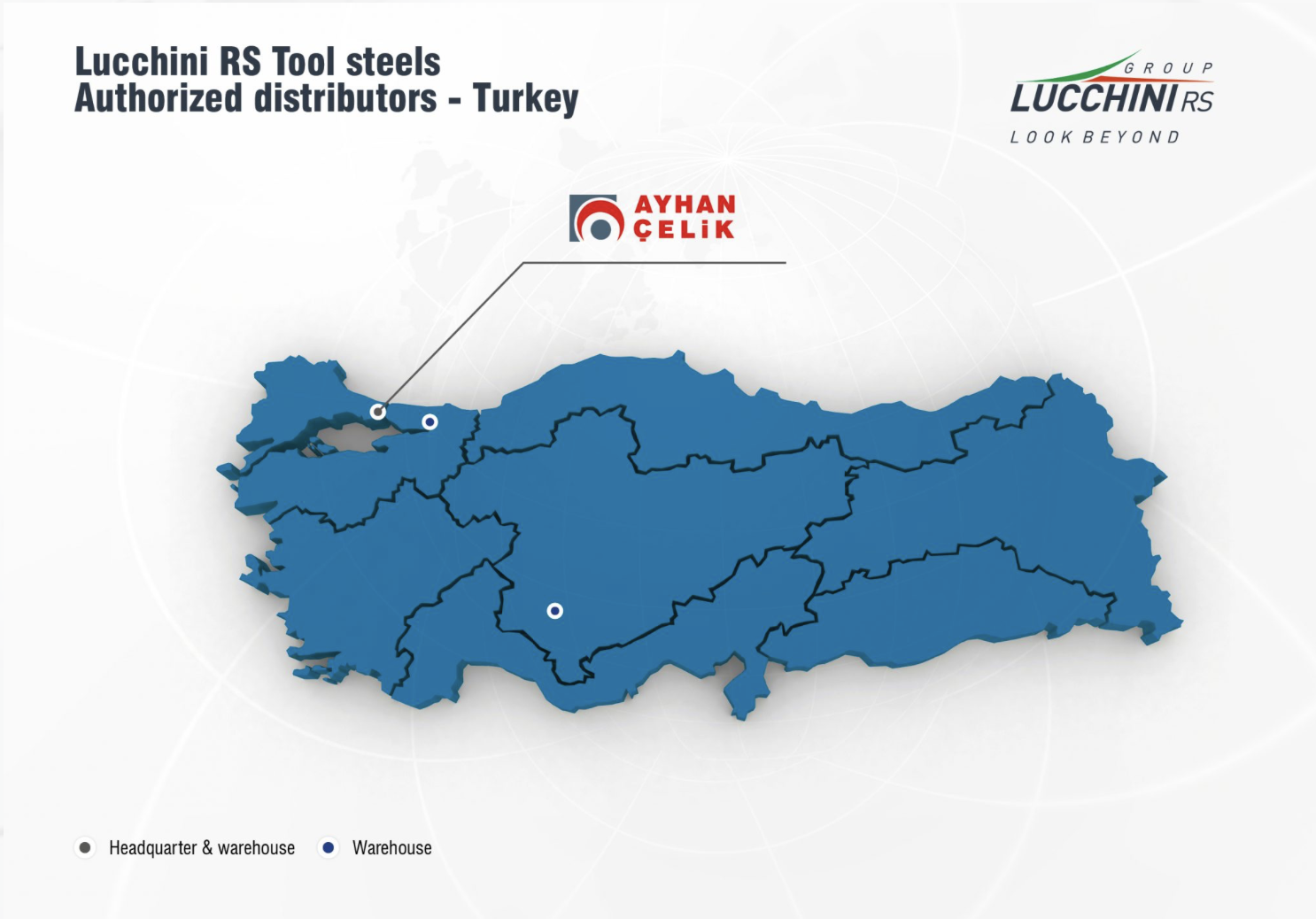

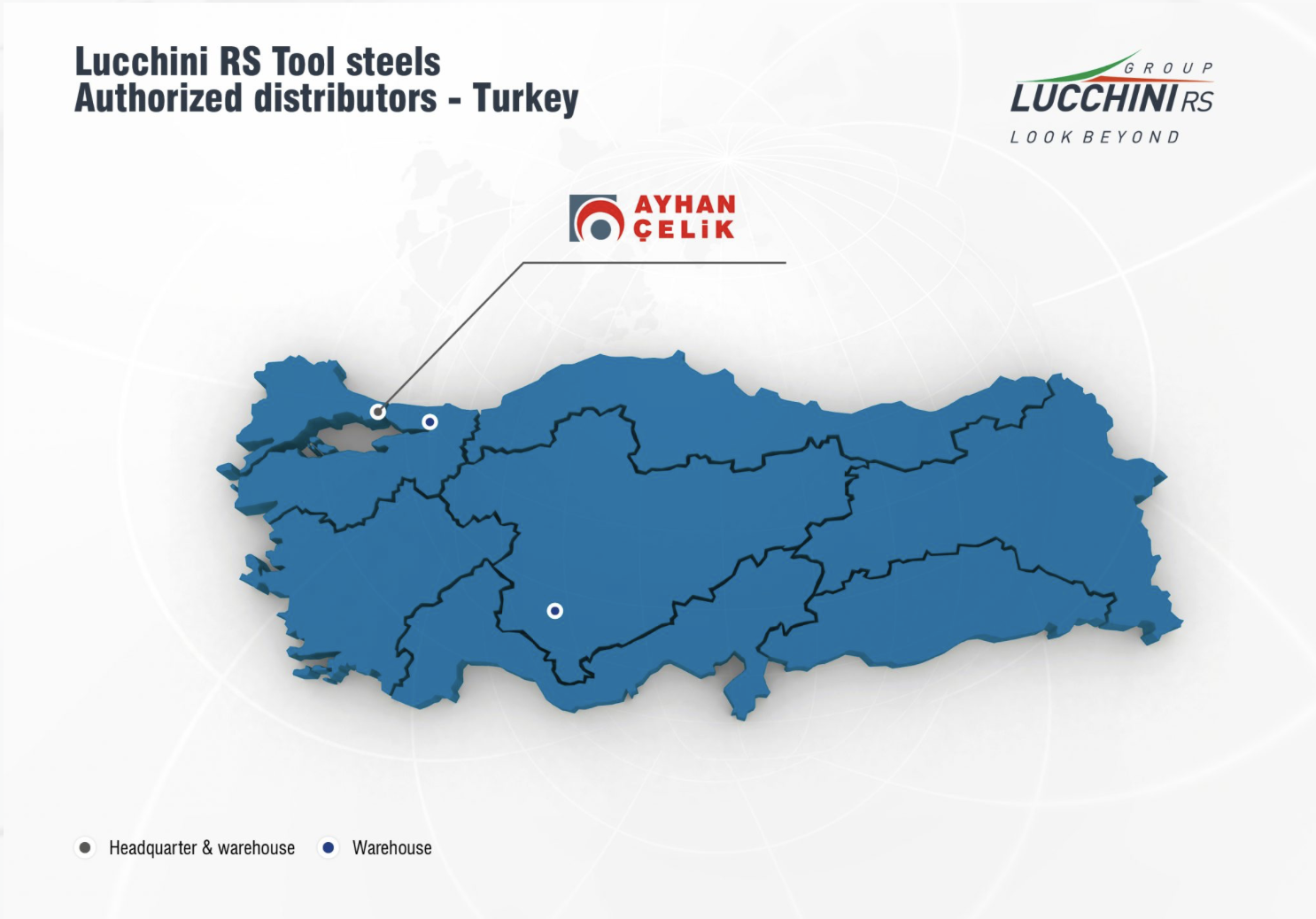

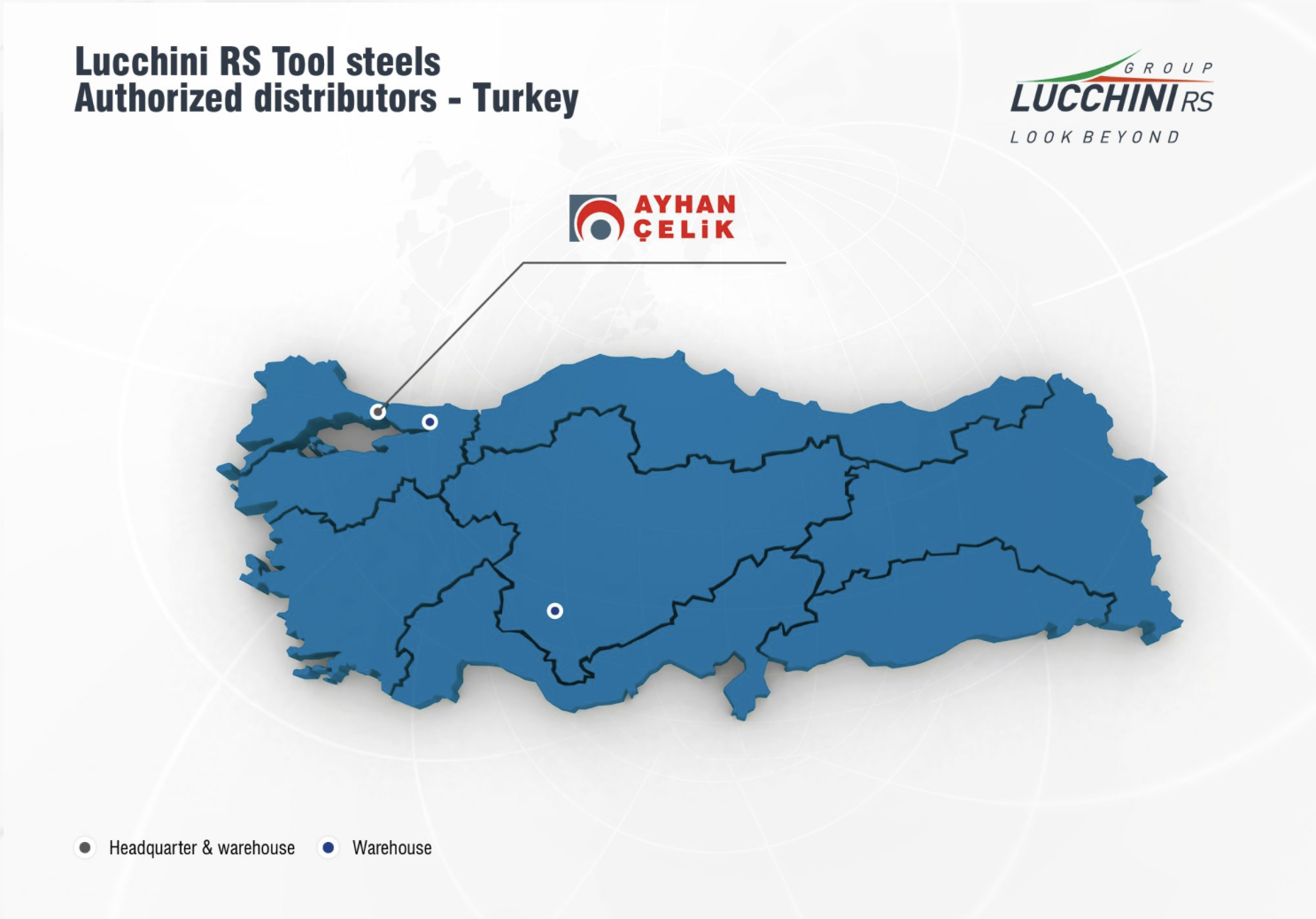

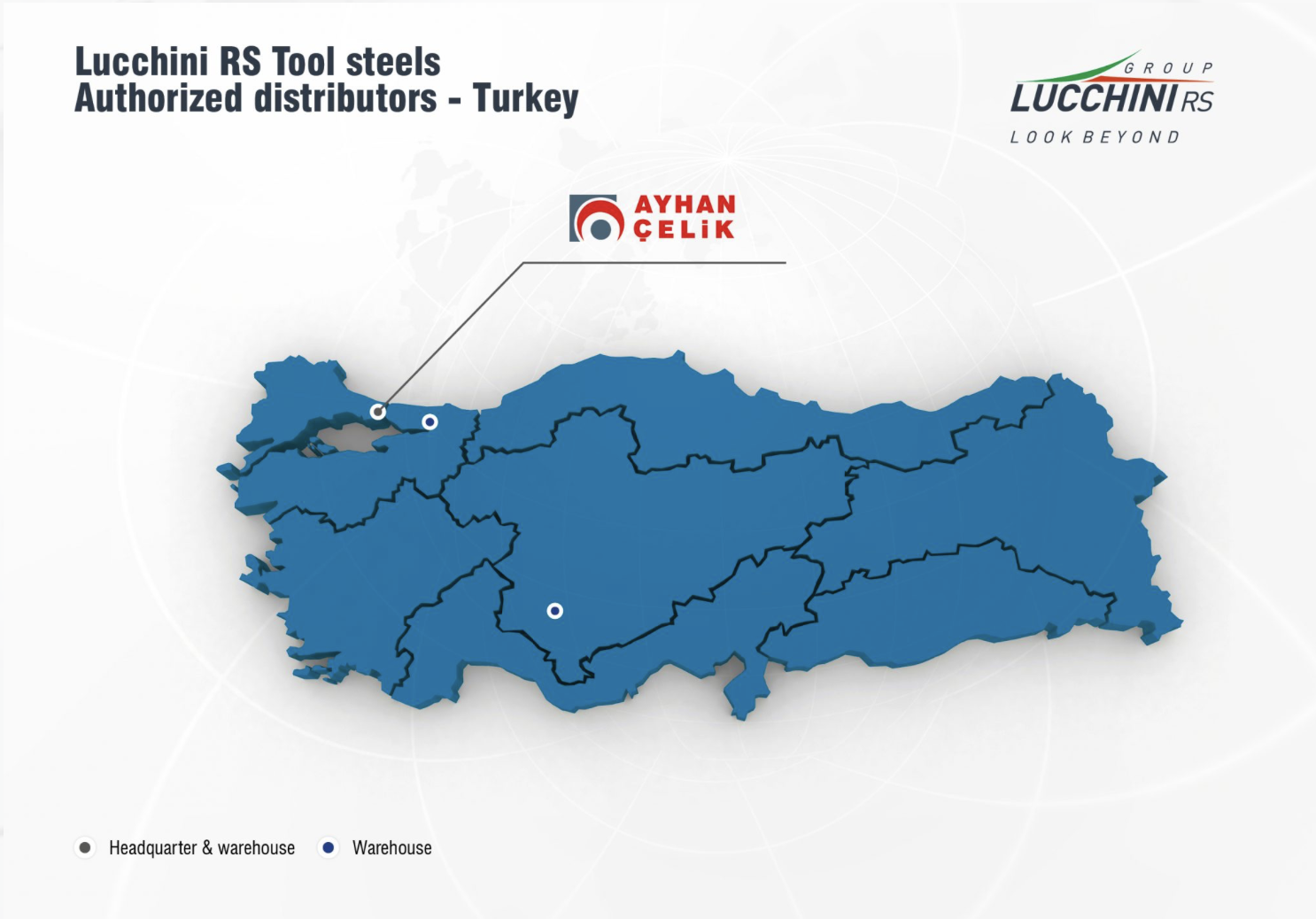

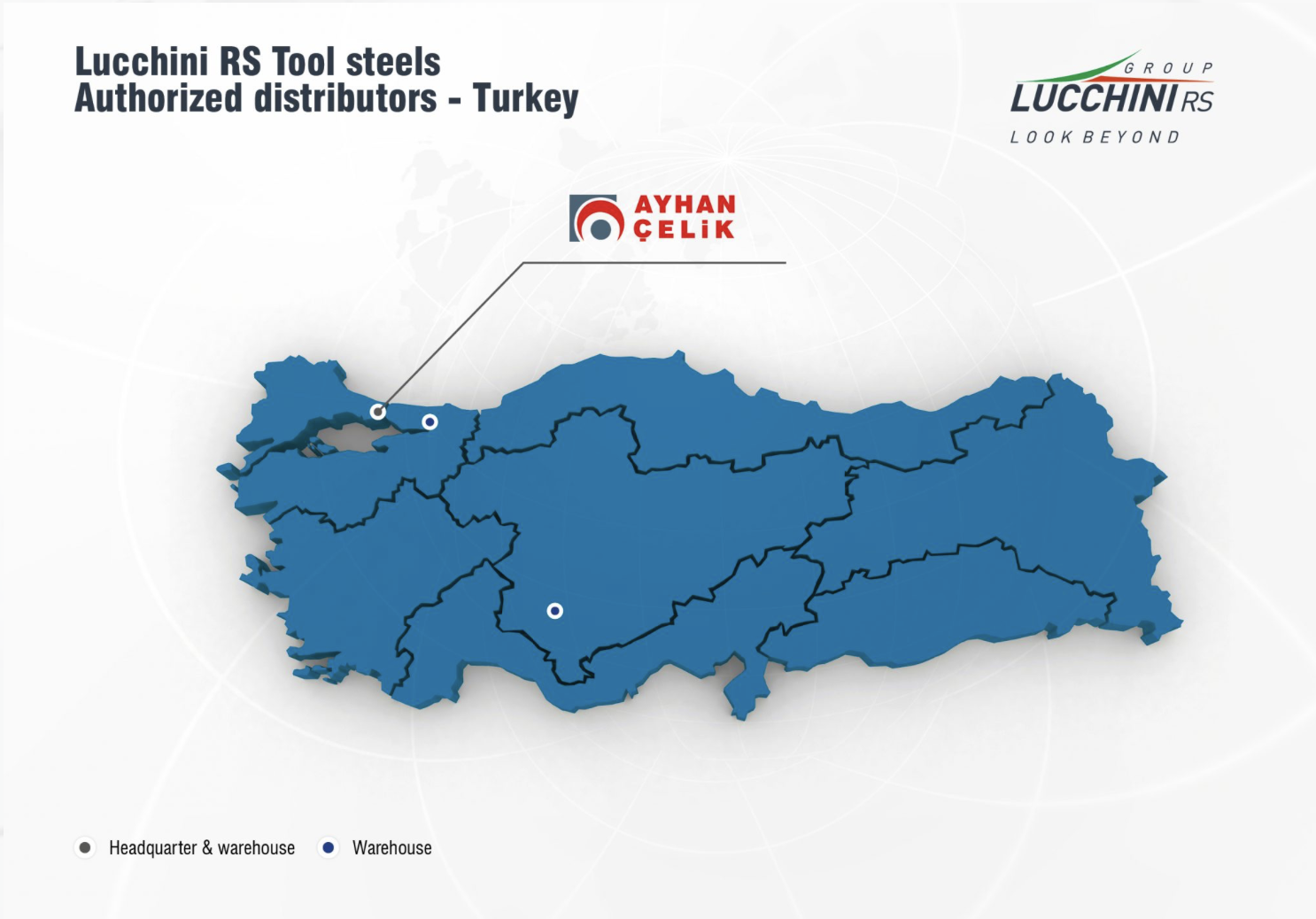

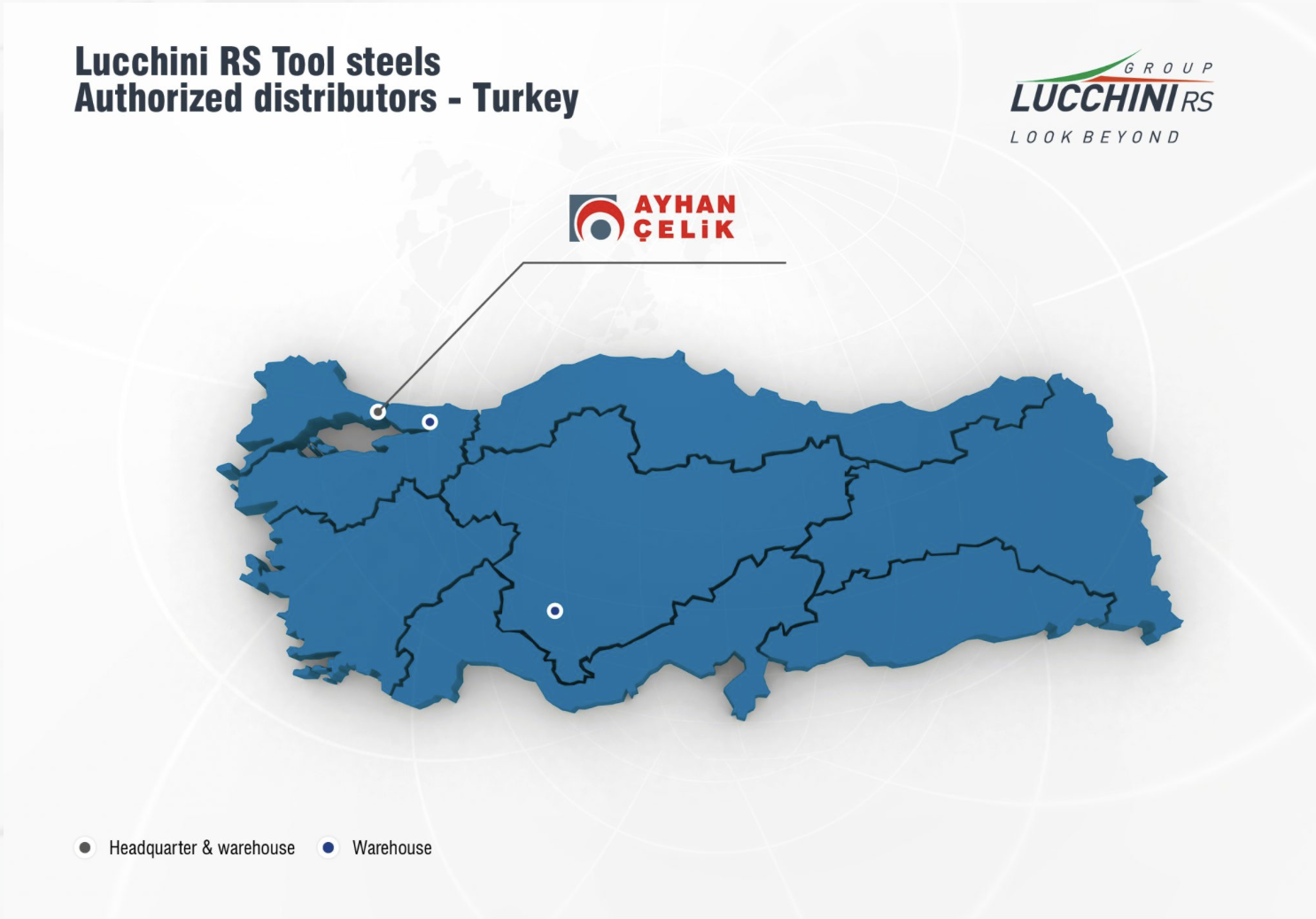

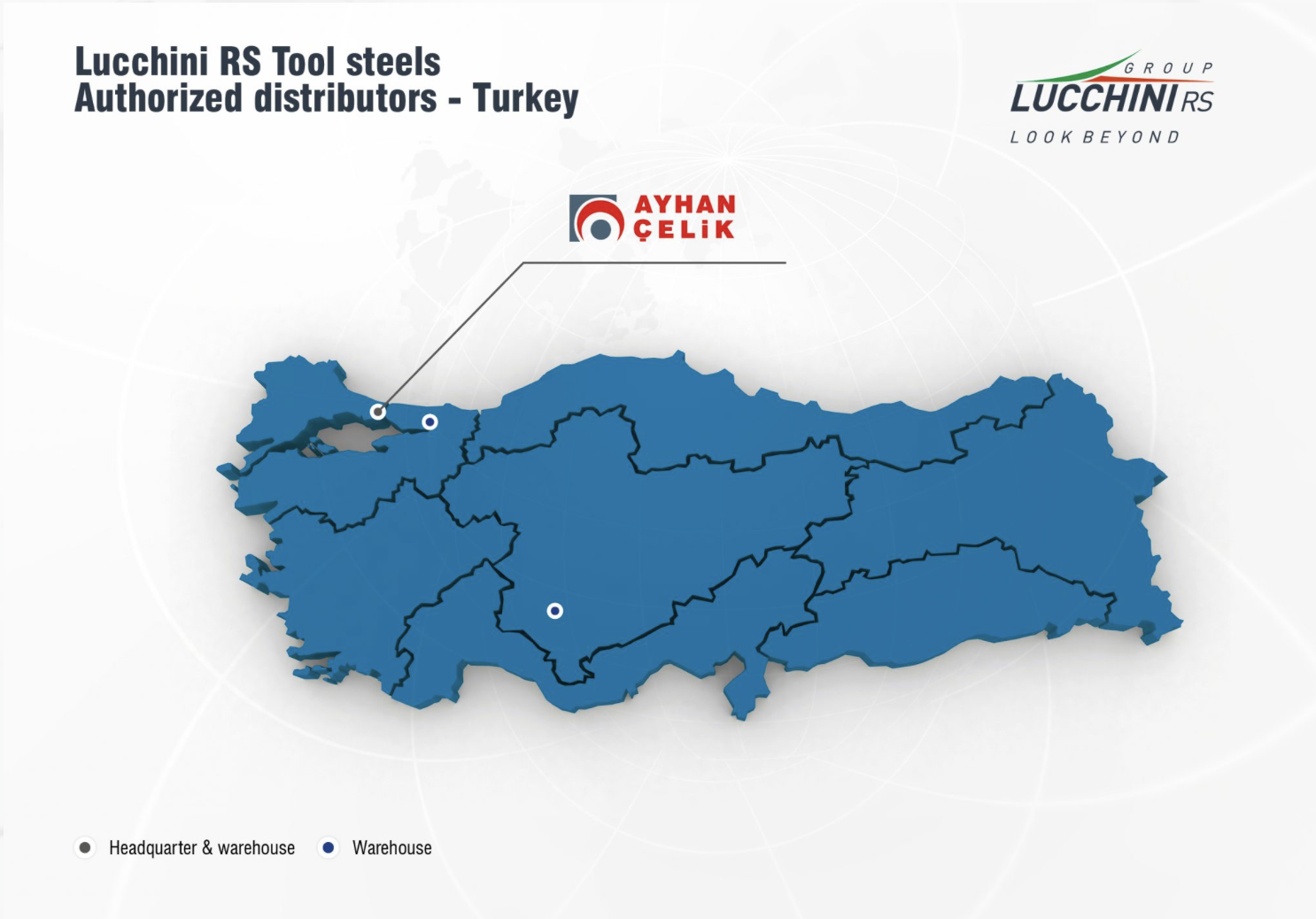

AYHAN TAKIM ÇELİK A.Ş.

İkitelli OSB Metal İş San Sit 17. Blok No: 1 / Başakşehir / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 549 1355

|

Hall: 12A

Stand: 12A-109A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Our company, which has been serving in Iron and Steel sector since 1980, has become one of the leading companies of the sector by continuing its progress with self-confident steps every day with its experience, quality and professional staff. Nowadays, in the developing steel industry where costs are important, we are bringing reasonable price with quality and serving to our customers. The tool steel in our product range is presented to our valued customers in good quality and fast under all guarantee conditions that the manufacturer company has provided us. Our company has documented its quality with the breakthroughs it made in 2006 (ISO 9001-2008) and took great steps towards institutionalization, keeping customer satisfaction at the highest level and adopting strong staff, fast and high quality service. Our firm, which operates with the loaded stock volume, has succeeded to be a leading supplier company with its serial diameters, standard laminates and large-sized billets in its stocks. We provide service to all our employees in order to present the quality to our customers at the shortest possible time with every band saw in our world, to maintain current customer satisfaction and to be able to get up even more day by day. Every piece cut is prepared by the authorized operator for both the weight and the size and we are ready to ship. The metallurgical engineers in our company follow the heat treatment service we offer and the materials we sell to our customers are subjected to heat treatment in vacuum, atmosphere controlled or fluidized bed furnaces by selecting the correct heat treatment process according to the place of use and working style. Our company has been the leader company in the sector with renewing itself and increasing investments every day by keeping the customer satisfaction constantly on the front panel.

LUCCHINI 2312 is the pioneer alloyed steel grade designed for the manufacture of small and medium sized injection and compression moulding dies. LUCCHINI 2312 represents the ideal option and the pioneering solution for pre-hardened moulds that need excellent machinability properties, thanks to a careful addition of a suited sulphur range after proper deoxidation of liquid steel.

LUCCHINI 2738 is the special pioneer pre-hardened alloyed steel for moulds with an high degree of through hardening, machinability and polishability. LUCCHINI 2738 has been developed for large dimension moulds with an high degree of through hardening in the section, thanks to the special calibration of the chemical analysis, particularly due to the adding up to 1.30% Nickel by alloying.

KEYLOS® 35 // KEYLOS® 35 EVO is Lucchini RS most recent and innovative tool steel for plastic moulds. If compared to the standard steel grades available on the market, such as AISI P20 and WN 1.2738, KEYLOS® 35 // KEYLOS® 35 EVO can be considered an advanced solution dedicated to the plastic injection and compression moulds, especially for medium and big size. The state-of-the art manufacturing process, together with the balanced chemical composition are key factors in ensuring the high quality and performances of KEYLOS® 35 // KEYLOS® 35 EVO Thanks to special heat treatment process and suited chemical analysis KEYLOS® 35 // KEYLOS® 35 EVO is characterized by excellent hardenability across the block. The low carbon equivalent value improves the weldability and homogeneity.

KEYLOS® 40 // KEYLOS® 40 EVO is a special and innovative pre-hardened alloyed steel, suitable for the manufacture of big size injection moulds. KEYLOS® 40 // KEYLOS® 40 EVO represents and synthesis and the perfect balance of the all the grades normally applied in this field and it is suited for a very wide range of applications in the plastics industry. Thanks to an accurate design of the chemical alloying elements and thanks to a special heat treatment, KEYLOS® 40 // KEYLOS® 40 EVO is characterized by a high degree of through hardening and it is suited when is required greater toughness balanced with very high hardness through to the core.

LUCCHINI 2311 is the pioneer of the mould alloyed steel grades, designed for the manufacture of small and medium sized moulds. LUCCHINI 2311 is the best classic option for the production of blocks with low and medium thickness, that need a high degree of homogeneity of hardness, mechanical properties and toughness in the whole section of the mould.

ESKYLOS® 2343 EVO // ESKYLOS® 2344 EVO is the new version of the high alloyed Chromium-Molybdenum-Vanadium Hot Work Tool steels family, designed by Lucchini RS for the most demanding high pressure Light Alloys (Al-Mg) die casting moulds. Thanks to the optimized chemical analysis (P<0.0015%, S<0.003% and low secondary elements content), together with the Electro Slag Re-melting process, followed by special forging and specifically designed heat treatment procedures, ESKYLOS® 2343 EVO // ESKYLOS® 2344 EVO achieves all the requirements imposed by NADCA #207 specification ensuring an high level of material s quality. ESKYLOS® 2343 EVO // ESKYLOS® 2344 EVO is preferred in IML molds that require high toughness, thermal conductivity and polishability.

It has been developed starting from the experience of ESKYLOS® 2340 grade, optimizing the Molybdenum (Mo) content and adding special micro-alloying elements such as Tungsten (W) to improve characteristics. ESKYLOS® OptiMo fully meets NADCA #207 specification concerning the annealed microstructure and banding segregation in the core of the block, the most critical position. The impact capability testing is performed according to NADCA #207 specification, one of the most important worldwide reference for die-casting application. ESKYLOS® OptiMo is preferred in IML molds that require high toughness, thermal conductivity and polishability.

W 1.2085 is a 16%Cr mould steel with improved corrosion resistance properties, thanks to the chromium addition. Furthermore, specific sulfur improves the machinability response. The grade delivered in quenched and tempered condition has a fully bainite martensite microstructure and typical hardness of 320 HB. The grade is not designed for highly polished or etched surfaces. This steel is commonly used for mould steel applications including holders or support plates subjected to wet working and/or storage conditions.

W 1.2316 is a mold steel with improved corrosion resistance properties, thanks to the addition of chromium and molybdenum. The high cleanliness/homogeneity of the steel makes it specially adapted to fine polishing (mirror finish). This steel is commonly used for mold steel applications including cores, inserts and mold cavities working or stored in humid environments. For any corrosion application, manufacturing of corrosive materials (PVC).

The company has no registered brand information.

TR

TR