| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

AZMOON POLYMER SEPAHAN

7th Street, 104 Avenue, Montazerieh Industrial Park, Isfahan / / / IRAN, ISLAMIC REPUBLIC OF

|

Contact Info: +98 913 013 2445

|

Hall: 2

Stand: 217

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Azmoon Polymer Sepahan Company Commenced its operations in 2014, relying on technical and engineering expertise as well as scientific and practical experience in designing and manufacturing laboratory equipment for the polymer industry. The management structure of this company, relying on the technical expertise and experience of its personnel, has consistently taken dynamic and systematic steps to enhance the quality of its services for production and laboratory units.

Determination of wear resistance of tires using rotating cylindrical method Used for quality control, comparative tests, test of compliance with judgment of Research and study activities Included a sample holder with standard diameter and the ability to adjust the height of the sample with standard angle deviation Included a rotating cylinder with the diameter of 150 mm and length of 500 mm and a speed of 40 rpm Ability to perform the test in rotating and non-rotating sample modes Included a 4.3-inch color touch screen for easy settings Provision of vertical pressure force of 5, 10 and 20 N by standard weights Equipped with Plexiglass as protection for safety and do not spread of samples Ability to adjust the wear distance at different levels Designed and manufactured in accordance with ISO 4649 and ASTM D5963 standards

Measurement of elastic elasticity of rubber in a specified hard range, by pendulum method Equipped with 4.3-inch color touch screen for easy setting Featured with a strong pendulum and is equipped with a standard spherical hammer Designed based on impact center and has a capacity of 0.5 J Featured with automatic pendulum release system Equipped with test holder with the ability to adjust the position to hold the test with different thicknesses Display the return height and stiffness of each test digitally Designed and manufactured in accordance with ISO 4662, ASTM D7121, DIN 53512

CNC milling machine with the ability to prepare samples for various tests such as: tensile, impact, and bending tests Equipped with three separate drive axles using stepper motors with high precision encoders to accurately measure the displacement of the machine axes Featured with a motor spindle with a maximum speed of 18,000 rpm Equipped with a special single drill for preparing perfectly polished polymer samples Included with suitable clamps to hold different types of samples without any vibration Designed in accordance with ISO 8256, ISO 527, ISO 179, ISO 180, ISO 6259, ASDM D638

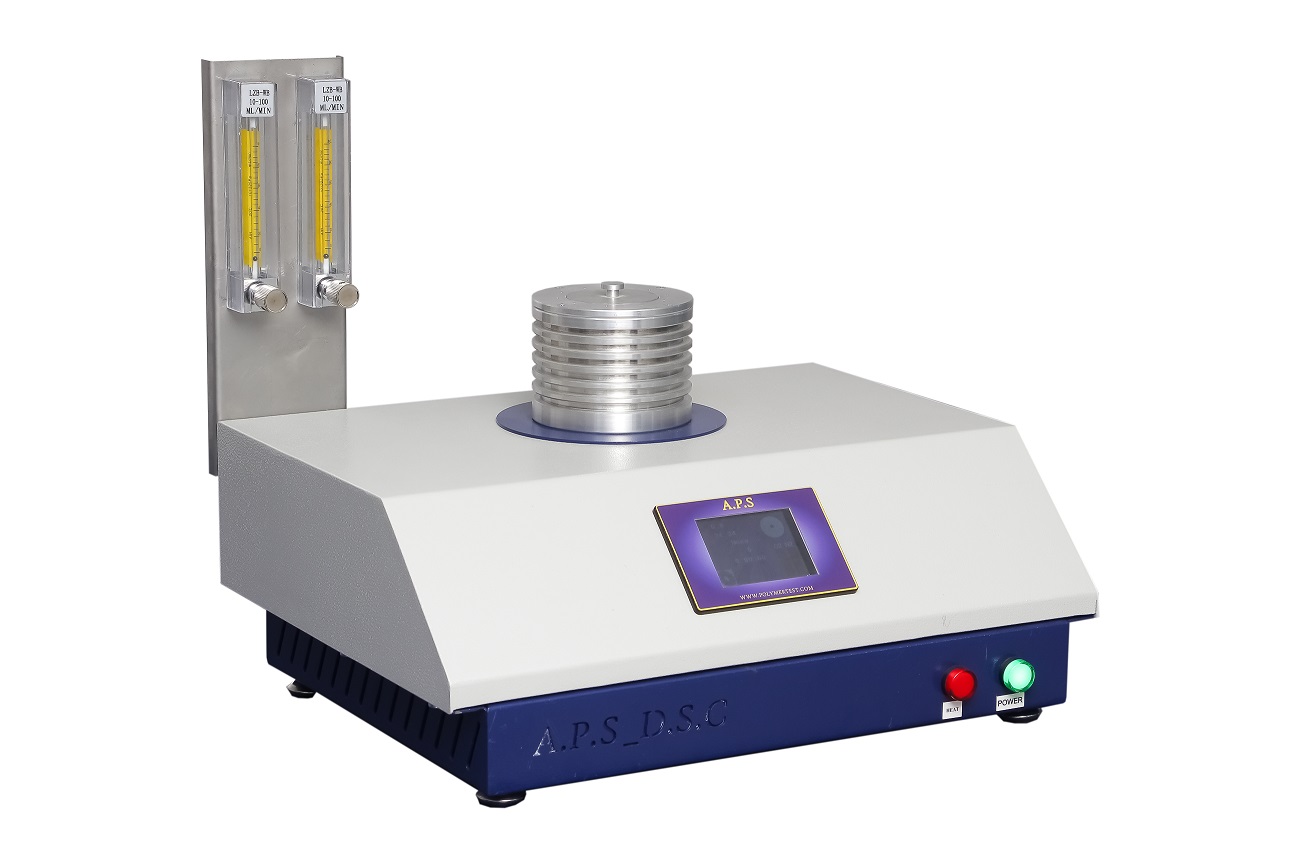

Determination of the oxidation induction time for polymer products using Dynamic Difference Calorimeter technique The ability to perform the test both for raw material and final product Drawing diagrams of temperature and enthalpy based on time continuously in the form of automatic scale Equipped with gas-fired valves of oxygen and nitrogen entree gases with automatic switching capability Double-point calibration according to the standard and with a cooling system Furnace with the ability to increase the temperature up to 400 C and precision of 0.1 °C and with the ability to adjust the desired temperature increase rate PC connectivity to receive data and doing tests through USB port Test operation accordance with the standards ASTM D3418, ASTM D3895, ISO 11357-6, EN 728

Determination of internal pressure resistance of pipes and fittings at different time intervals by performing hydrostatic pressure and burst test Connection via network port (LAN) and wireless connection (Wi-Fi) to the computer, with advanced software to control and perform tests as well as plotting pressure, time and temperature Equipped with a 7-inch color touch screen for easy settings Equipped with a logger to store test results without the need for a continuous connection to the computer for up to 10,000 hours Ability to determine the rate of pressure increase and pressure control in the range of 2% and -1% of the set pressure Equipped with electric motor pump, pressure sensor and high quality solenoid valves

Determining the rheological and mechanical properties of rubber mixture during curing Drawing diagrams of S, S , S , and temperature vs time Determining the curing time, scorch time and rate index for elastic momentum curves Equipped with 7-inch color resolution touch screen for easy set up Included with a comprehensive computer software to control, report and save test results Direct contact of the models with the sample without delay and temperature drop with the ability to change the models separately Equipped with bar elements from ambient temperature up to 250 with the resolution of 0.1 C Protection of device and automatic closing system by DC motor Operating torque range 0 to 250 d N.m with an accuracy of 0.01 d N.m Constant oscillation frequency at 0.5 to 2 Hz with a tolerance of 0.1 Hz Ability to select the ranges of oscillation mechanically (0.5, 1 and 3 degree)

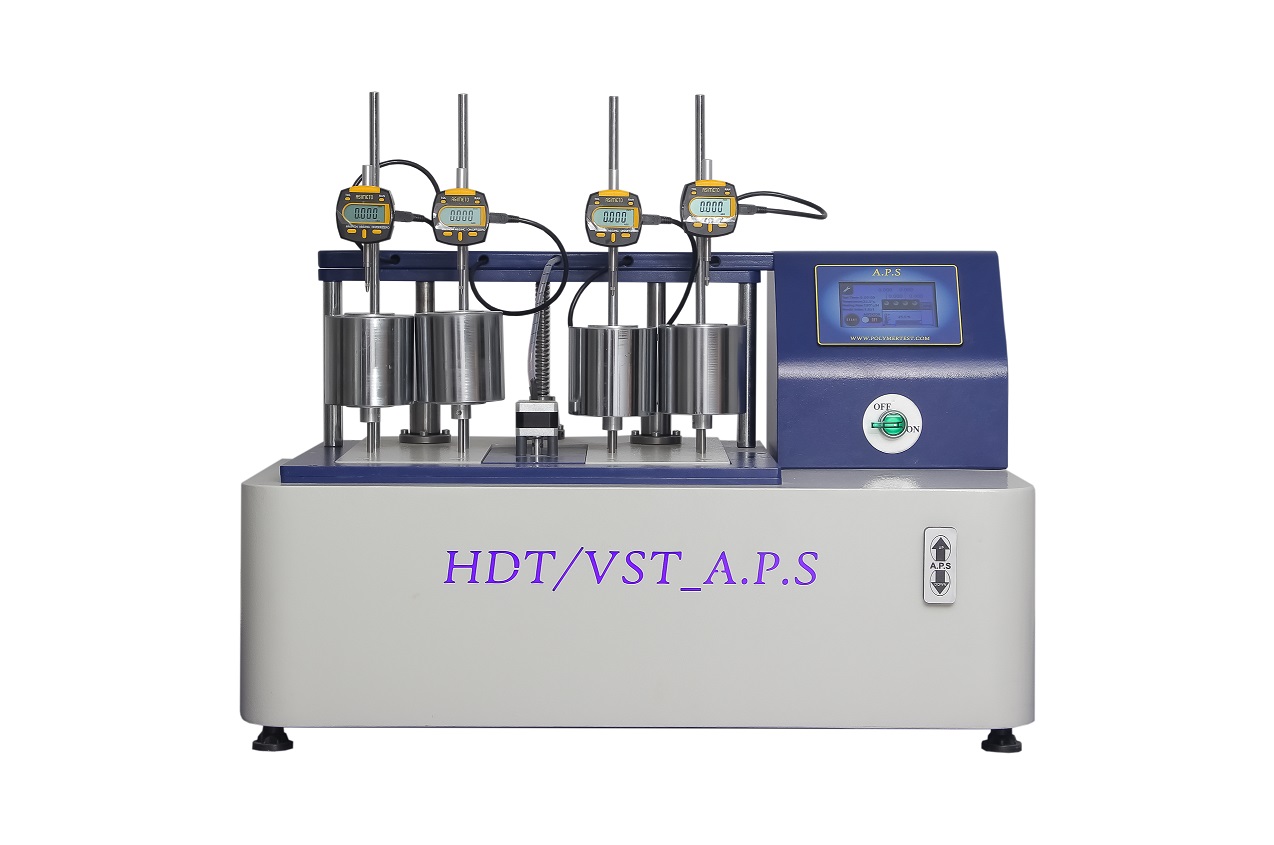

Equipped with digital indicator clock with accuracy of 0.001 mm to show middle floating amount Fluid circulation system for simulating the fluid temperature The ability to increase the uniform temperature inside the enclosure with 10 °C to 150 °C temperature rates Digital controlling system with 4.3-inch touch screen monitor to easy test setting VICAT test setting and HDT with capability of installation to PC with computer software for registering test results and drawing temperature and penetration diagrams Fluid cooling system for cooling the fluid quickly for retest In accordance with the standard ISO 75 - ISO 306 - ASTM D648 - ASTM D1525

System operation electro electrically using wing screw and AC Servo motor and driver with Close Loop control system Ability to perform tests: Tensile test, Compression, Cyclic, Bending, Creep Relaxation in accordance with international standards ASTM, DIN, EN, ISO Ability to install specialized jaws, internal and external extensometers and the ability to install a furnace and perform hot testing up to a temperature of 10oo °C Equipped with C3 class load cells in different capacities with a combined error of less than 0.02°10 full scale (< +-0.02% FS) Equipped with accurate displacement sensor to measure device cross head displacement Included with a powerful software under the Windows operating system and providing a complete test report without restrictions, storage and retrieval of previous test data Full computer device control and connection via USB port with power calibration capability and extensometer displacement

Featured with 2 thermal zones by separate elements and thermocouples with a temperature recording with the accuracy of 0.1 °C Equipped with an automatic cutting with the ability to adjust the cutting time with the accuracy of 0.01 seconds Standard tungsten carbide die The temperature range is up to 350 °C PID controlling system equipped with 4.3-inch color touch screen Force application by standard weights Equipped with all accessories such as piston, cleaning shaft, cleaning cloth, weights and .... Included with a protective screen to prevent the distribution of cutting samples Included with a compartment to put side equipment Designed and manufactured of machine components (dip- piston- cylinder) in accordance with ISO 1133

Falling Weight test method Equipped with a 4.3-inch color touch screen in order to easy test setting With an automatic rammer lifting and automatic release mechanism Included with an automatic height adjustment system with an accuracy of 1 mm With a suitable rigid support to hold the sample up to 630 mm Maximum fall height 2000 mm (adjustable as required) Included with jacks (D90, D25, D20) and weights suitable for different standards Ability of the Anti Reboune mechanism, which prevents re-impact on samples Ability to test in two ways Staircase, Round-Clock Designed in accordance with ISO 3127, ISO 11173

No represented companies found.

- A. P. S

TR

TR