| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

BAŞAR AĞIR MAK. SAN. VE TİC. LTD. ŞTİ.

Birlik Sanayi Sitesi 2. Cadde / Beylikdüzü / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 875 0410

|

Hall: 11

Stand: 1106B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Since 1961 Basar Makina working in many fields of industries including food and textile, our company accomplished many first and original projects renewing its name as Basar Agir Makina in 1994 and continuing its services to many other companies in many fields extending its vast experiences together with plastic pipe machine and equipments manufacturing. Our company has its own know how and technology in many fields and sharing them with other plastic pipe manufacturing companies such as its own pipe manufacturing lines while producing and designing special projects to these companies since the evolution of plastic development from past to today in Turkey. Some of our equipments and mechanism are patented. Adjustable Calibrating Sleeves are just an example to such Technologies amongst others. Basar Makina has the necessary staff and tools for fulfilling all the needs in pipe machine manufacturing with its universal and CNC machine platform. Since 1961 Basar Makina is being a Turkish power with its new technology production and consistently development as usual. Also Basar Makina will resume to service you again for a long time.

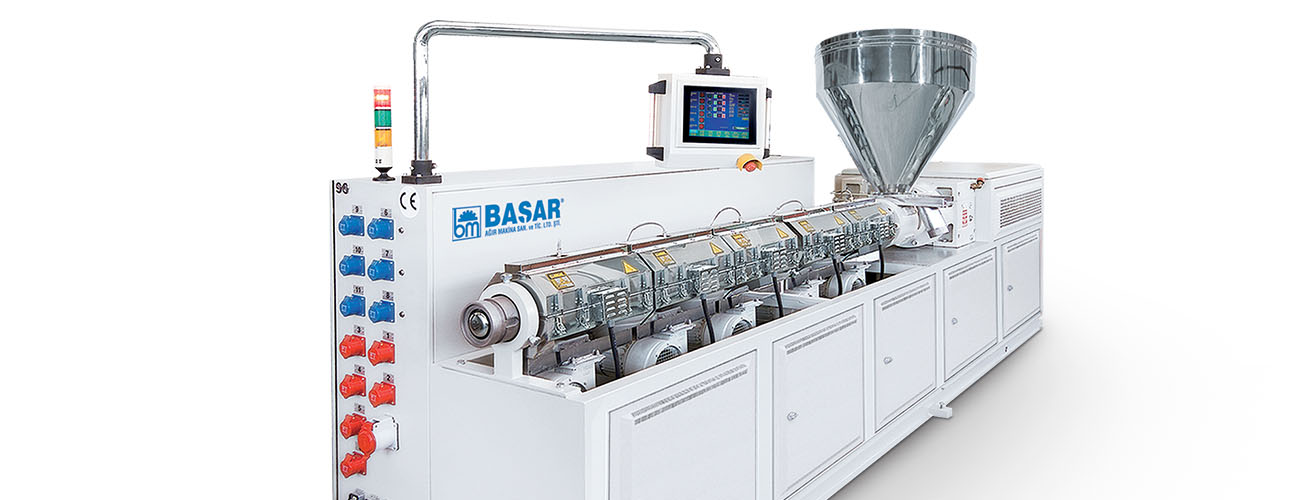

Extruder machines are exists on the based on polymer extrusion technology. Extruders melts the raw material in unit time from the top funnel and makes furtherence operation with compressing. Hence plastic raw material both melted and also pressed to desired density. Our extruders gives maximum control skills by melt pressure indicators, temperature sensors and touch control panels which are on the machine. In generally, it is used single screw extruders for PE and PP extrusion lines, and twin screw extruders for PVC and PVC compound products.

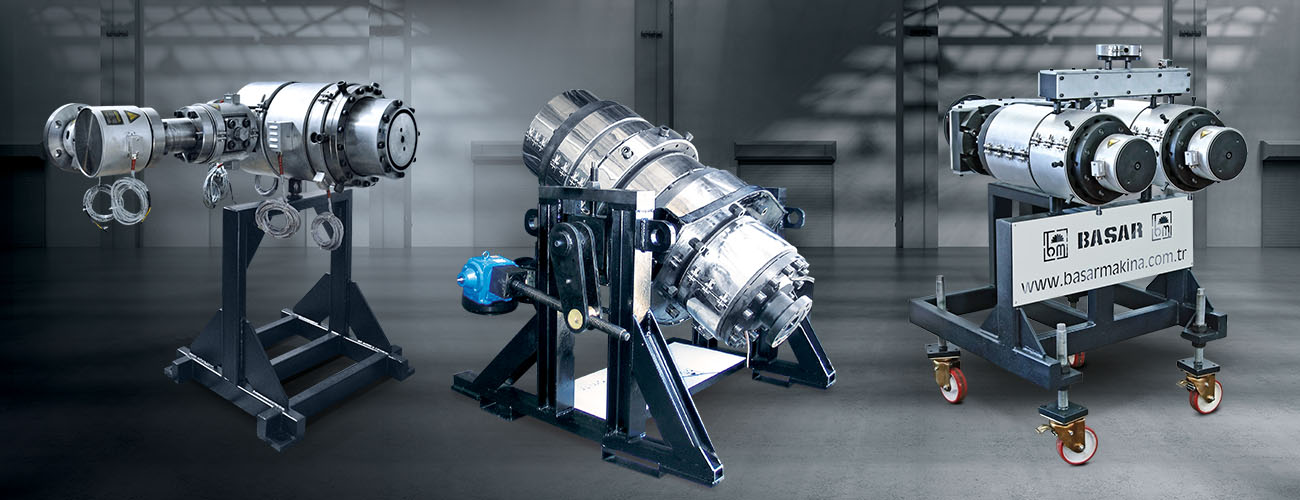

Pipe heads which are also called a kind of pipe moulds, are tied outlets of extruders. This dies gives pipe form to plastic material and adjusts the wall thickness of pipes. Our company supplies wide working range heads with high capacity to our customers.

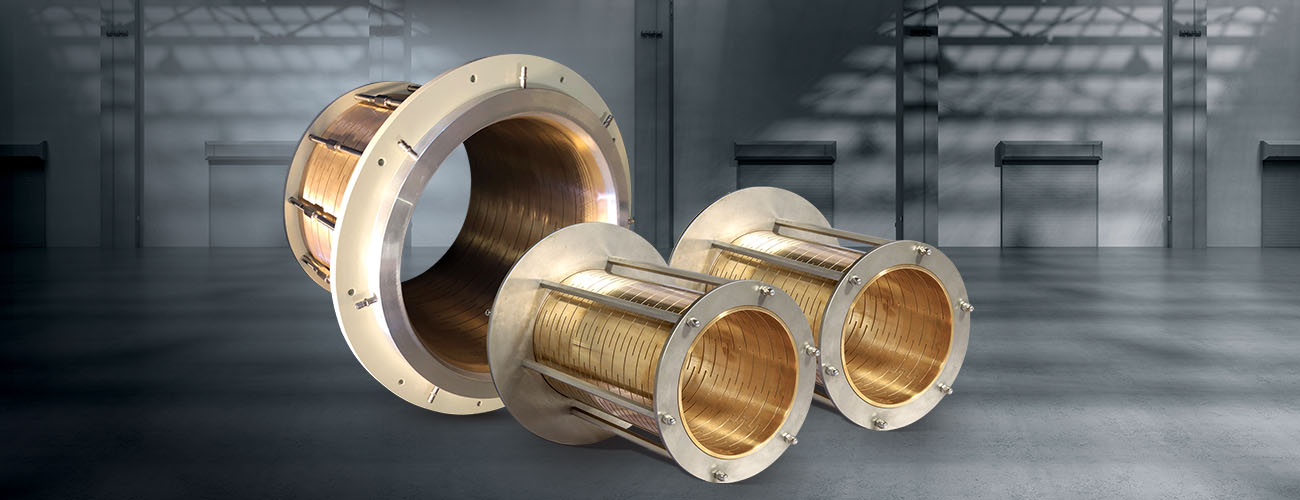

Adjustable calibrating sleeves are the parts which has much easiness and offers many advantages in calibrating systems. Adjustable calibrating sleeve s most imortant superiority against normal calibrators is possibility to get all pressure classes of pipes from PN4 upto PN32 in one calibrator. Also adjustable sleeves gives possibility for special productions. You can get both in ISO standard pipes and also inch standard pipes from one calibrator. Furthermore it is not be needed to change vacuum degrees if the raw material changes. In addition these sleeves provides to save high ratios of raw materials by approching 0 in outside diameter tolerance.

Vacuum calibrating tanks are one of the important stages of plastic pipe extrusion lines. These tanks applies vacuum to calibrate the pipes at a defined diameter and also avoids pipes to have ellipse shape while producing. Also pipes and calibrating sleeves are cooled effectively by nozzles which are inside the tanks.

Cooling tanks are used after vacuum tanks for effective cooling of pipes after calibration. The cooling principal is based on spray cooling by nozzles which are placed around inside the cooling tanks. Also they can be used as a cooling baths by not spraying from nozzles if needed.

Haul-off units works synchronised with production speed while plastic pipe or profile producing, and catches plastic material without damages it and pulls it to following unit. Generally there are two pieces of caterpillar or belts for profiles, but for plastic pipes; the number of belts changes according to pipe sizes.

Cutting units are designed for plastic pipes which are produced by length- wise and packaging in this way. These units cuts the pipes after reaching the defined length of pipe. Operator enters this cutting length to machine control screen before starting the machine. The cutting operations are in cycles and these cutters works synchronised with production speed. The pipes which are cut, are tilted to right and left by tilting table and packaging operation is done on this tilting table.

Pipe coilers are developed for stocking flexible pipes into coils. These coilers works synchronised with production speed of extrusion lines and winds pipes orderly with a pre-defined lenghts.

Corrugated pipes and kinds of corrugated pipes like drainage pipes are nowadays commonly used in piping systems because of having very important advantages. Corrugated pipes come forward because of its superior specifications in drainage applications, sewage systems and waste chemical liquid material systems. Especially they are used frequently because of its high abrasion resistant and being strong against chemical materials. Corrugated pipes have inside production material PE or PP so they are very suitable for sewage applications because of corrosion resistant. Also its light weight provides easiness while transportation and application.

End closures are the auxiliary equipments using for testing the hyraustatic pres- sure endurance of plastic pipes. End closures also called Pressures test covers and used with hydrostatic pressure devices. The both side of pipes are closed with these covers and given pressurized water inside it according to its standards. After filling the pipe with water, these equipped pipe waited inside at a defined temperature of water and applies for endurance and inflection tests.

No represented companies found.

The company has no registered brand information.

TR

TR