| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

JIAXING YINGCAN TRADING CO.,LTD

No.3 Yuanzhong Rd, Maoyang Town, Xiangshan, Ningbo City, Zhejiang Province / / / CHINA

|

Contact Info: +8618268664499

|

Hall: 11A

Stand: 11A-132D

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Ningbo Tiansu Machinery Technology Co., LTD. Is a professional production of high-precision energy-saving series of plastic injection molding machine manufacturers. The main production of injection volume 70g-10000g, clamping force 700KN-12500KN, more than 20 specifications of plastic injection molding machine. Ningbo Tiansu Machinery since its inception, the spirit of quality first, reputation first for the purpose of society and the majority of users; In order to participate in the international market competition, the company through personnel optimization combination, condensed a group of high-quality with pioneering spirit of operation, technology, management personnel; Cultivate a group of highly responsible, hard-working, skilled staff; Since the product was put into the market, it has won the praise and trust of domestic and foreign users. Ningbo Tiansu Machinery Technology Co., Ltd. quickly became a rising star in China s plastic machine industry. The company promises we will, as always, repay the society and users with high quality, high efficiency and energy saving products and services!

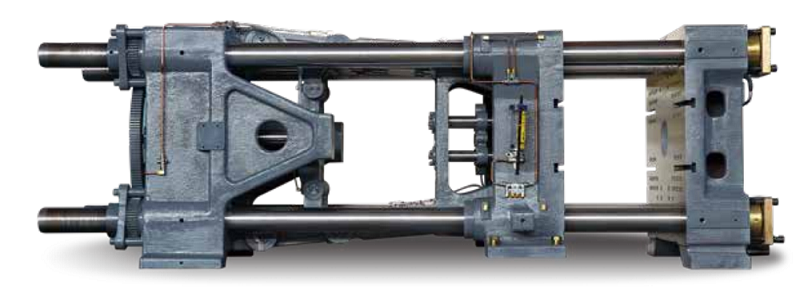

Clamping components by computer simulation,the overall optimization from the kinematic and dynamic characteristics,using, the technology-leading, five-point double toggle oblique clamp-ing,template by finite element analysis,innovation of the hollow spherical structure of the head board,plywood box frame steucture and templates,siamese,etc.To ensure mold parts is high rigidity and high reliability,to achieve a smooth opening and closing mold,mode-locked solid,large distance between the lever mold can be installed.

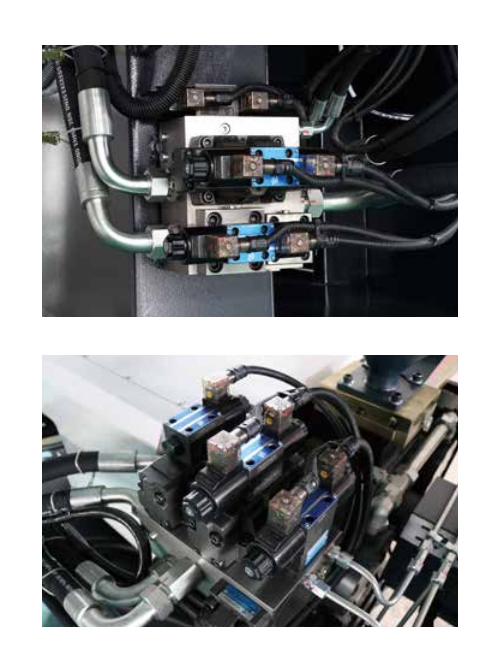

1.Energy saving: Standard with precision and energy saving servo power system, the output drive system is sensitivelyaltered, according to the actual need of the plastic parts being produced, avoid energy waste.Depending on the plastic parts being produced and the material being processed, energy-savingability can reach to 20%~80%. 2.Environmental protection: The machine is running low noise, low power consumption;, European Famous hydraulic hose, usingthe DIN standard spherical joints, valve plate with G thread sealing plug, to prevent oil pollution. 3.Convenient: Visible and dischargeable oil tank, easy for hydraulic circuit maintenance, self-seal suction filter,reasonable placed hydraulic pipe fittings, maintenance will be easy and convenient.

No represented companies found.

- TİANSU

- OUTAİ

TR

TR