| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

SHANDONG HUASU PLASTIC TECHNOLOGY CO., LTD

No 8, YUNXI ROAD, JIAOZHOU BAY INDUSTRIAL ZONE ,JIULONG STREET OFFICE, JIAOZHOU, QINGDAO CITY / / / CHINA

|

Contact Info: +86 532 8727 3398

|

Hall: 11A

Stand: 11A-129F

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

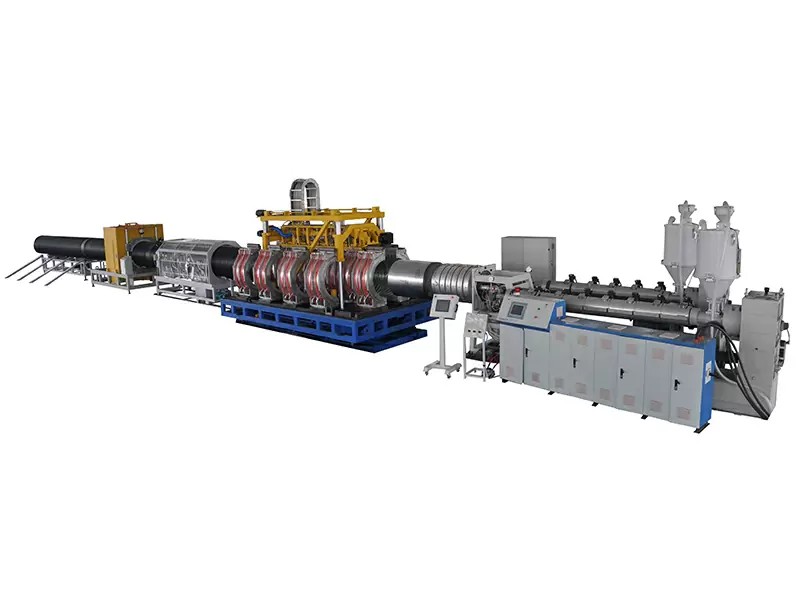

Shandong Huasu Plastic Technology Co., Ltd which located in Jiaozhou Bay Industrial Zone in Qingdao City was built in 2002. The company covers an area of 50,000 square meters, with current building area of 25,000 square meters. It is only 10 kilometers away from Qingdao Jiaodong International Airport. Our company has very strong technology and innovating ability so that various kinds of pipe extrusion line are exported to Europe, Russia, Central Asia, Southeast Asia, Middle East, North and South America, Oceania, Africa etc.. Our company always adheres to the spirit of exploration and innovation, keeping up with the development trends of the global plastic machinery industry. Our produced PE high speed double wall corrugated pipe line (Ф32-Ф2000mm), PVC/PVC-M high speed double wall corrugated pipe line(Ф110-Ф2000mm) are highly recognized by domestic and foreign users with high quality and efficient product image.

The molds adopt the double flow channel structure and nitriding polishing processed die head. This makes the adjustment of partial wall convenient and fast and ensures the thickness of the inner and outer wall uniform and stable. The latest design of closed pressure water cooling structure, full cooling, multi-point distribution vacuum system, higher efficiency, faster production speed. Online double wall belling function and automatic lubrication system. The advanced shuttle structure and reasonable track design make the module run more smoothly and the forming section longer, which is conducive to rapid production. lower energy consumption and cost saving. It s simple and fast to replace the mold, saving time and cost. Online EPS uninterruptible power supply ensures the automatic return of the forming worktable in case of sudden power failure, so that the mould block can be separated from the water sleeve in time. Siemens professional PLC programming control cutting machine, double knife cutting, simple and sensitive operation,accurate, stable and reliable. Human machine interface, extrusion synchronous control system, with remote communication function and realize remote fault diagnosis and troubleshooting. Production line series is divided into ID32-ID63,ID75-ID200,ID110-ID300, ID200-ID600,ID500-ID800,ID800-ID1200,ID1200-1D2000(mm).

The molds adopt the double flow channel structure and nitriding polishing processed die head. This makes the adiustment of partial wall convenient and fast and ensures the thickness of the inner and outer wall uniform and stable. The latest desian of closed pressure water cooling structure, full cooling, multi-point distribution vacuum system,higher efficiency, faster production speed. Online double wall belling function(PVC-M) and automatic lubrication system. The advanced shuttle structure and reasonable track design make the module run more smoothly and the forming section longer,which is conducive to rapid producion.lower energy onsumption and cost saving. Online EPS uninterruptible power supply ensures the automatic return of the forming worktable in case of sudden power failure,so that the mould block can be separated from the water sleeve in time. Siemens professional PLC programming control cuting machine, double knife cuting, simple and sensitive operation, accurate, stable and reliable. Human machine interface, extrusion synchronous control system, with remote communication function and realize remote faut diagnosis and troubleshooting. Production line series is divided into ID110-ID300,ID200-ID600,ID500-ID800,ID800-ID1200,ID1200-ID2000 (mm). This line is widely used in municipal engineering, underground sewage pipe of residential area, sewage discharge and other fields.

The molds adopt the double flow channel structure and nitriding polishing processed die head. This makes the adiustment of partial wall convenient and fast and ensures the thickness of the inner and outer wall uniform and stable. The open water cooling structure and multi-point distributed vacuum system make the cooling efficiency high and easy to form. Online double wall belling function and automatic lubrication system. The advanced horizontal structure and reasonable track design make the chain drive the mould block run more smoothly. Online EPS uninterruptible power supply ensures the automatic return of the forming worktable in case of sudden power failure,so that the mould block can be separated from the water sleeve in time. Siemens professional PLC programming control cutting machine, double knife cuting, simple and sensitive operation, accurate, stable and reliable. Human machine interface, extrusion synchronous control system, with remote communication function and realize remote faut diagnosis and troubleshooting.Easy to operate.

The molds adopt the double flow channel structure and nitriding polishing processed die head. This makes the adjustment of partial wall convenient and fast and ensures the thickness of the inner and outer wall uniform and stable. The latest design of closed pressure water cooling structure, full cooling, multi-point distribution vacuum system, higher efficiency, faster production speed. Online double wall belling function and automatic lubrication system. The advanced shuttle structure and reasonable track design make the module run more smoothly and the forming section longer, which is conducive to rapid production. lower energy consumption and cost saving. It s simple and fast to replace the mold, saving time and cost. Online EPS uninterruptible power supply ensures the automatic return of the forming worktable in case of sudden power failure, so that the mould block can be separated from the water sleeve in time. Siemens professional PLC programming control cutting machine, double knife cutting, simple and sensitive operation,accurate, stable and reliable. Human machine interface, extrusion synchronous control system, with remote communication function and realize remote fault diagnosis and troubleshooting. Production line series is divided into ID32-ID63,ID75-ID200,ID110-ID300, ID200-ID600,ID500-ID800,ID800-ID1200,ID1200-1D2000(mm).

This series of production line can produce PE/PP/PA/EVA/PVC/PVDF single wall corrugated pipes according to diferent materials. The production line is cooled by water through the gear drive module template,the module is air-cooled and the forming speed is fast. The molding process is divided into two types: internal pressure blow molding and vacuum molding. The module has high machining precision, uniform corrugated shape, consistent seams, and smooth inner and outer wals. The single wall corrugated pipe production line mainly includes single screw extruder,forming machine,dle mold, cooling device,counter, winding machine, and can continuously produce pipes of different pipe diameters. The production line series are divided into Ф10-Ф40mm,Ф50-Ф110, Ф75-Ф200 (mm).

It adopts high speed and high efficiency single screw extruder, equipped with low-noise fan and high speed gear reducer to ensure high speed and high performance extrusion. The mold is made of high quality 40Cr raw materials and imported processing center to ensure the accuracy of processing and the uniform extrusion of raw materials. The vacuum sizina water tank is made ot stainless steel,with advanced circulating water circuit and vacuum degree adjustment device and precise water level and temperature automatic control system. The cutting machine adopts chipless automatic cutting, and the cutting section is smooth and flat. The whole production line adopts the intelligent control of German Siemens PLC control system. It has the characteristics of convenient operation, stable and reliable continuous production, etc. The production line series can be divided into Ф20-Ф75, Ф50-Ф160,Ф75-Ф250, Ф110-Ф315, Ф200-Ф400,Ф315-Ф630,Ф630-Ф1200 (mm) according to requirements.

It adopts high efficiency conical twin screw extruder, equipped with low-noise fan and high speed gear reducer to ensure high speed and high performance extrusion. The mold is made of high quality 40Cr raw materials and imported processing center to ensure the accuracy of processing and the uniform extrusion of raw materials. The vacuum sizing water tank is made of stainless steel, with advanced circulating water circuit and vacuum degree adjustment device and precise water level and temperature automatic control system. The cutting machine adopts chipless automatic cutting, and the cutting section is smooth and flat. The whole production line adopts the intelliaent control of German Siemens PLC control system. lt has the characteristics of convenient operation, stable and reliable continuous production, etc.

No represented companies found.

- HUASU

TR

TR