Melt Flow Indexer (Mfi) Testing Machine

Melt Flow Indexer (MFI) Testing Machine

Category:

Laboratory Test Equipment

This product is provided by the company ALARGE ALIÇ AĞACI MAK. ELEK. ARAŞ. GELİŞ. SAN. TİC. LTD. ŞTİ. . Please contact for more information.

Product Description

Melt flow indexer (MFI) is a testing method used to measure the flow properties of polymers. This method allows the polymer to flow at its melting point under a certain temperature and a certain load. The melt flow index value gives information about the viscosity and fluidity of the polymer. The melt flow indexer (MFI) device measures the flow rate of polymer at a specific temperature and under load. It is often used in the plastic industry. It is used to determine the fluidity properties of the polymer, ensure quality control and compare material properties. The use of this device plays an important role in the production process of the polymer and the quality control of the products. It can also be used to compare and analyze different polymer types and polymer blends. Melt flow rate (MFR) is a value obtained as a result of the test. MFR refers to the amount of molten mass of the polymer passing per unit time at a certain temperature and under a certain load. It is usually measured in grams per minute (g/10 min). Melt Volume Flow Rate (MVR) works on a similar principle, but it expresses the amount of melted volume of the polymer passing through per unit time. MVR is usually measured in cubic centimeters per ten-minute (cm³/10 min). When the calculated MFR value is compared to the MVR value, the density of the material used in the experiment at the test temperature is found. Both values are used to determine the flow properties of the polymer and to make comparisons between different polymer types. These values are important to ensure polymer processability, quality control and managing production processes.

Other Products of the Company

See AllHydrostatic Pressure Testing Machine

Hydrostatic Pressure Testing Machine

Hydrostatic Pressure Testing Machine Test (Water) Tank

Hydrostatic Pressure Testing Machine Test (Water) Tank

Hydrostatic Pressure Testing Machine End Caps

Hydrostatic Pressure Testing Machine End Caps

Universal Testing Machines

Universal Testing Machines

Similar Products

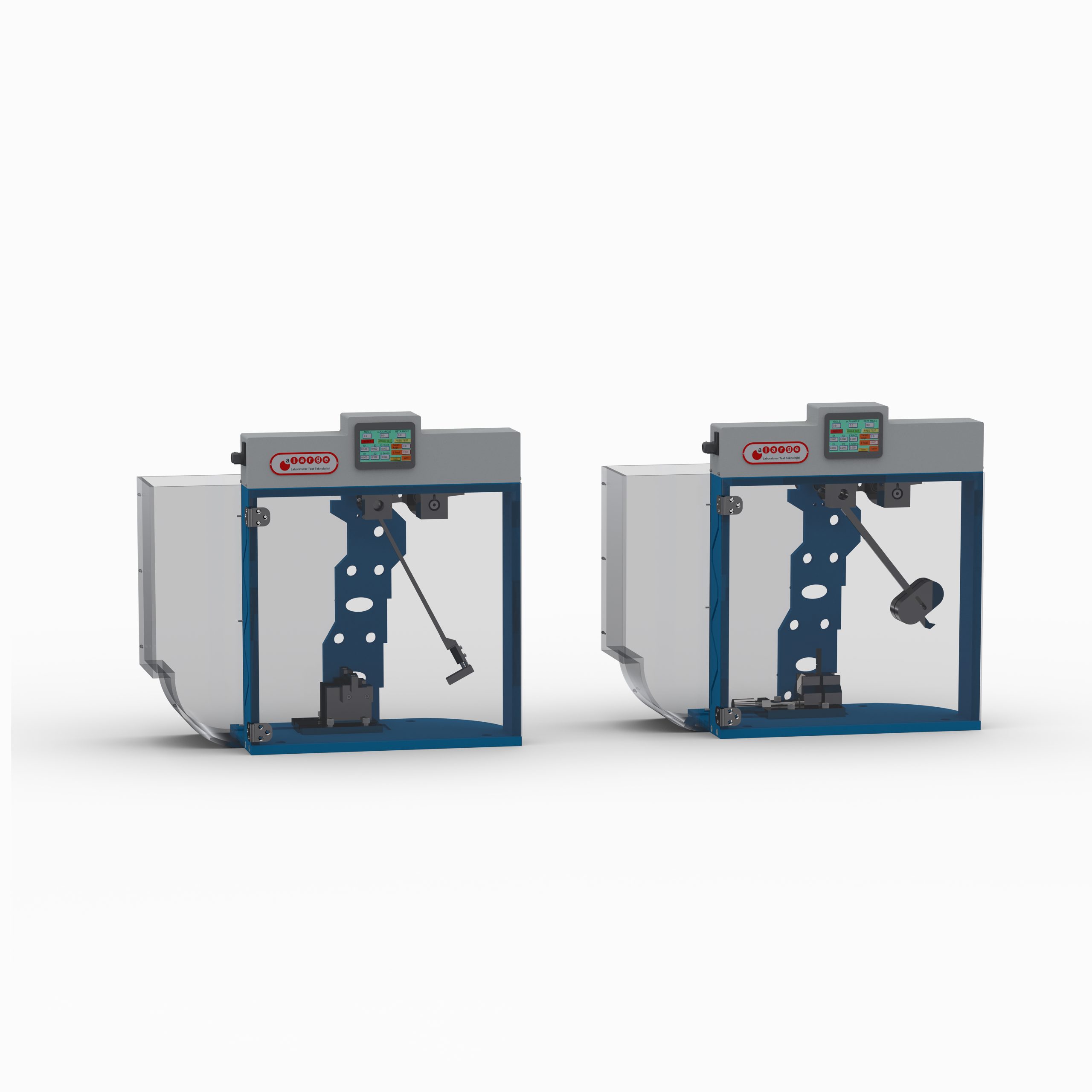

See AllPendulum Impact (Charpy & Izod) Testing Machine

Pendulum Impact (Charpy & Izod) Testing Machine

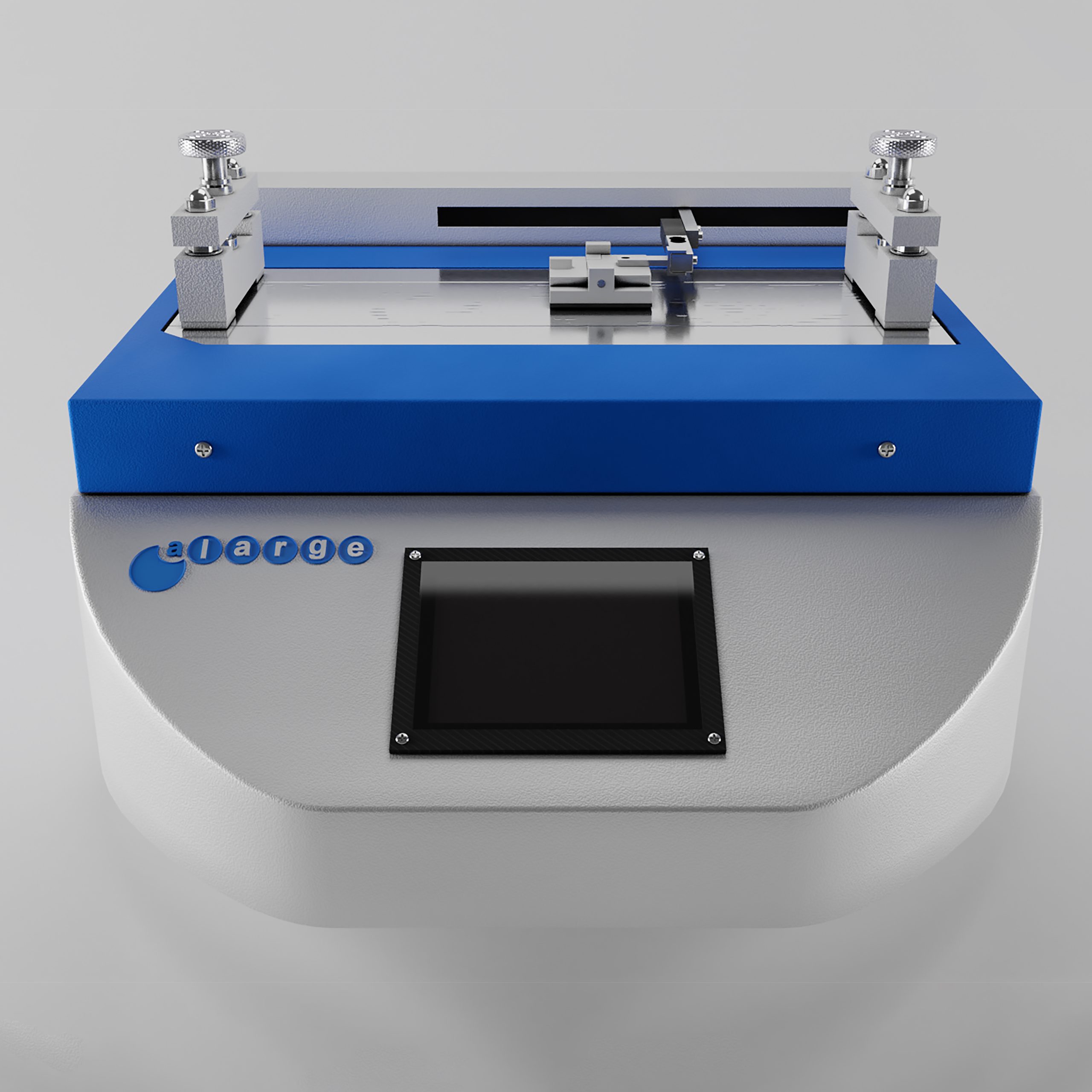

Coefficient of Friction Testing Machine

Coefficient Of Friction Testing Machine

Melt Flow Indexer

Göttfert Mi2.X Series Melt Flow Indexer

Falling Weight