Metro G

System solution - Conveying

Category:

Raw Material Handling And Drying Systems

This product is provided by the company MOTAN GMBH . Please contact for more information.

Product Description

METRO G is the most comprehensive and flexible material loader range on the market. It combines the best of two established material loader ranges – colortronic and motan. Whether simple or highly complex, METRO G’s modular building block system will provide you with an individual solution tailored to your needs.

Modular design

No product redundancy - as your production requirements change so does the material loader.

All material loaders are fully modular and can be matched to different throughputs and requirements depending on the application. Not only are there different material loader volumes but also different material inlet and outlet sizes which can be accurately adapted to suit throughputs and conveying distances.

De-dusting module

Guarantees consistent material quality for critical applications.

The de-dusting module removes dust from high performance engineering plastics directly at the hopper loader, sending them to the central dust filter via the air flow. These expensive materials, now dust-free, can be processed without further delay.

Vacuum module with Blow Back

Safe option for very dusty materials. The implosion vacuum module with blow-back function enables safe cleaning of the screen filter for very dusty materials. The standard implosion cleaning is reinforced by additional blasts of compressed air.

Tangential material inlet with trumpet air outlet

The ideal solution for fine or dusty materials. If the materials that you need to convey have a small granule size, are very dusty, or contain angel-hair, then the METRO G loaders can be supplied with a tangential material inlet. During conveying this produces a cyclone effect which is perfect for separating different types of materials. With the “trumpet” air outlet, the exhaust air speed is well below the levitation speed so that no granules or particles can be carried back to the central dust filter.

Membrane implosion vacuum valve

No compressed air required and guaranteed contamination free. The membrane implosion vacuum valve offers the same functions as the implosion vacuum valve but works without compressed air. Instead, the vacuum required for the switching process comes from the conveying system, which opens and closes the valve. This valve is therefore ideally suited for use in clean room applications.

Other Products of the Company

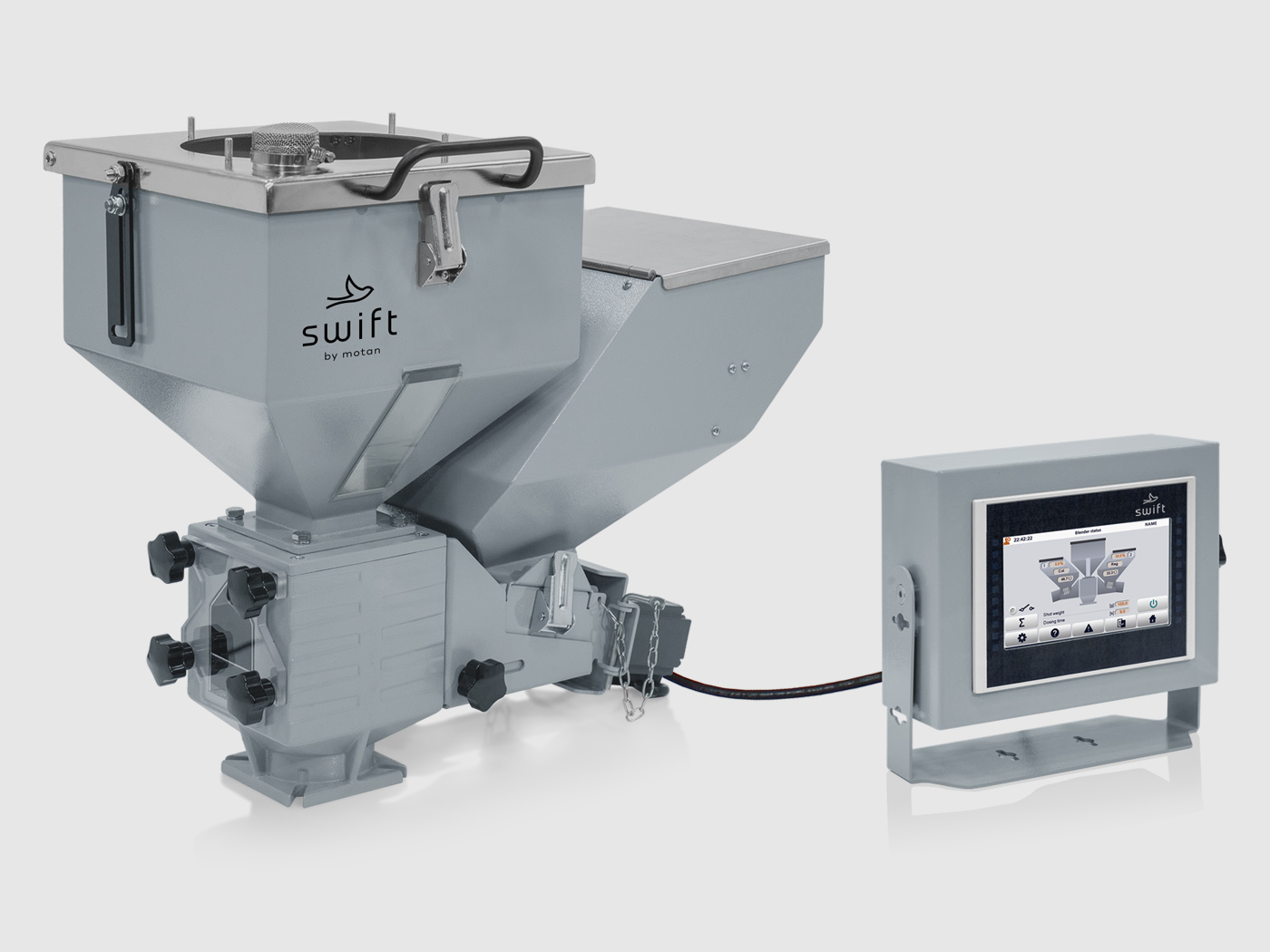

See AllPrecision Gravimetric Dosing & Mixing With Flexibility At A Competive Price

Sblend G

Modular Drying System For Flexible Drying Solutions

Sdry Mm/Md And Sdrybin

Volumetric Additive Dosing Unit

Scolor V

Compact Dryer With Integrated Conveying

Scompact

Similar Products

See AllDrying & Dehumidifying

Pet Crystallizers - Scr & Hopper Dryers

Auto Loader

Auto Loader

PLASTIC MATERIAL LOADER

Plastic Material Loader

Separation and Cooling Systems