Scompact

COMPACT DRYER WITH INTEGRATED CONVEYING

Category:

Raw Material Handling And Drying Systems

This product is provided by the company MOTAN GMBH . Please contact for more information.

Product Description

The sCOMPACT dryers are designed with flexibility in mind. The compact dryers offer an integrated solution, combining the drying and conveying of the raw material in one unit. The dryers are available in three versions, each with a drying bin of the size 80, 150 or 250 litres and up to three hopper loaders for conveying to the drying bin and two processing machines. As standard, this compact dryer is equipped with dew point control, overdry protection and dry air conveying function with line purging.

Thanks to a modern 7\" touch screen colour display, all conveying and drying functions can be shown and monitored in a user-friendly way. 16 user languages can easily be selected.

Dew point display and control

Optimised regeneration time saves energy. The sCOMPACT version of the dryer, offers dew point display and dew point control as standard. Regeneration of the molecular sieve is triggered when the maximum dew point set value of the return air has been reached. This value can be defined and set by the user and offers large energy savings.

Overdry protection

Protects material and saves energy. The standard automatic overdry function prevents material from being over dried. This reduces the heating capacity of the drying bin if the process return air temperature remains high for a long period of time. This function can be either enabled or disable dependant on your process requirements.

Integrated conveying

3-in-1 drying technology saves space. The integrated conveying function in the sCOMPACT saves you space and money as no separate conveying system is needed. It can control one drying bin hopper loader as well as the hopper loader on up to two processing machines including the blower and filter.

Dry air conveying & line purging

Maintaining material temperature and eliminating reabsorption of moisture. The sCOMPACT A version offers dry air conveying and line purging as standard. This is essential for hygroscopic materials which reabsorb moisture quickly. Conveying is carried out in a closed loop and dry, warm air is used for transporting the material to the processing machine. After every conveying cycle the material feedline is purge. So, maintaining material temperature and eliminating reabsorption of moisture.

Other Products of the Company

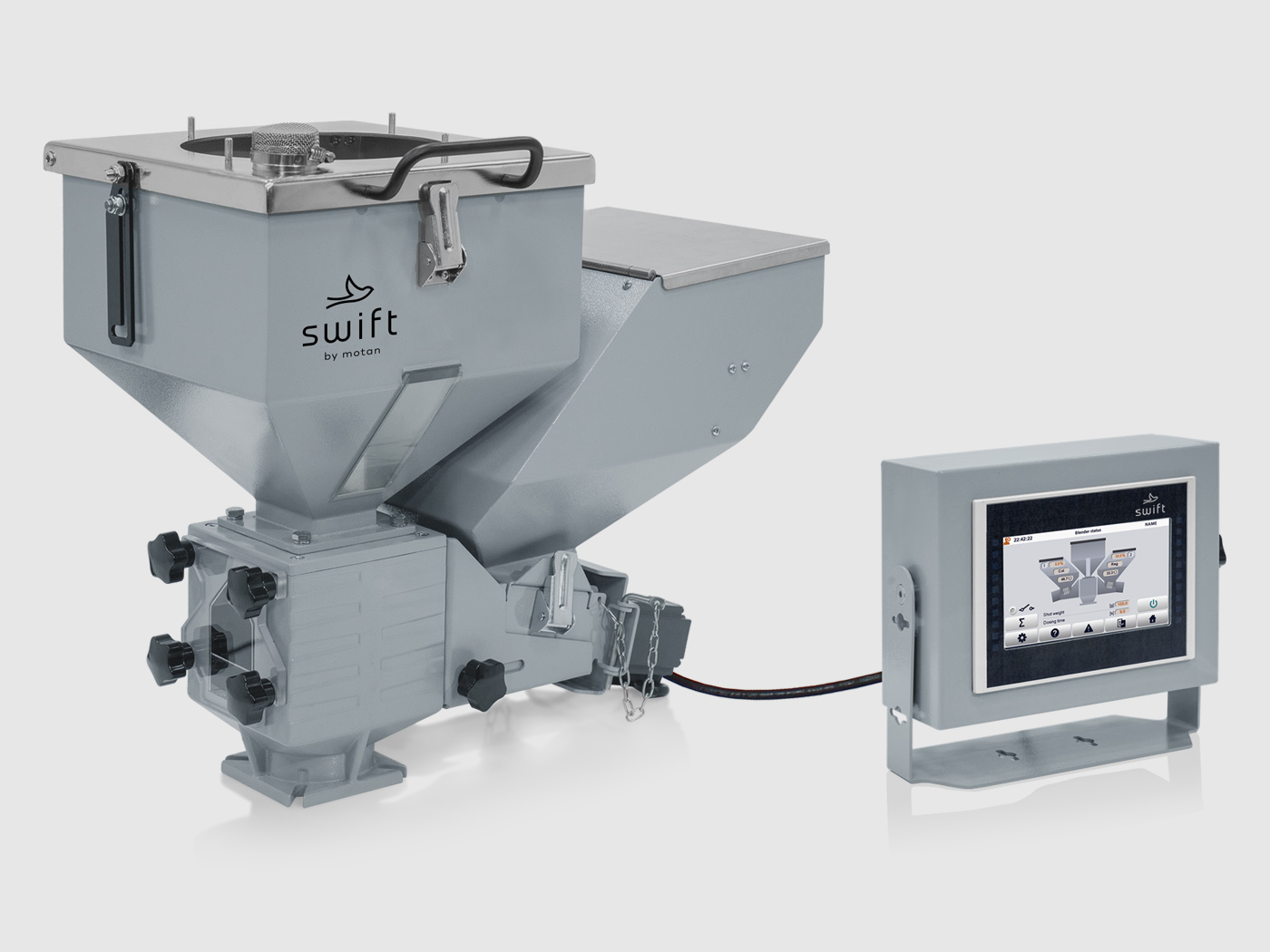

See AllPrecision Gravimetric Dosing & Mixing With Flexibility At A Competive Price

Sblend G

System Solution - Conveying

Metro G

Modular Drying System For Flexible Drying Solutions

Sdry Mm/Md And Sdrybin

Volumetric Additive Dosing Unit

Scolor V

Similar Products

See AllDEHUMIDIFYING SYSTEM

Dehumidifier

Separation and Cooling Systems

Vibrating Sieve

Auto Loader

Auto Loader

Drying&Dehumidifying