Bole Dk Series - Two Platen Injection Moulding Machine

Bole DK Series - Two Platen Injection Moulding Machine

Category:

Plastics Injection Molding Machines

This product is provided by the company FAVORİ GRUP PLASTİK VE MAKİNE SAN. TİC. A.Ş. . Please contact for more information.

Product Description

Operate independently to ensure German quality and present European perfonmance perfectly.

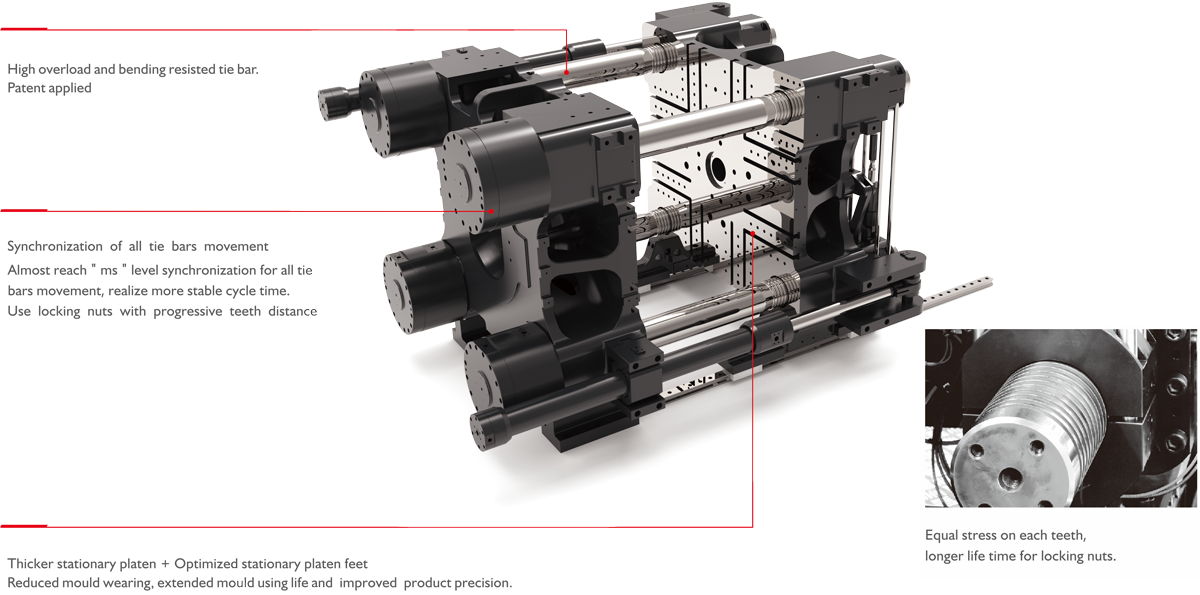

01. Break-resisting tie bar

Less stress for weak point tie bar, there is almost no risk of fracture. High overload and bending resisted tie bar.

02. High precision & rigidity linear rail

DK series two platen machines adopt high precision and high rigidity linear guide coordinates with siliding foot to support movable platen, guaranteening high positioning precision of movable platen and faster opening and closing speed. Without the problem of splashing lıbrication oil, the performance of whole machine gets further impovement.

03. High efficieny German designed plasticising system

Orginate from German design Plasticizing System, efficiency excess above 20% of domestic level.

Custom made complicated technical requirement, applied to special plasticizing system.

All series can fit with A/B/C screw, L/D ratio 23:1, to achive the best plasticizing effect and efficiency.

04. Vertical placed motors & pumps

The motor is placed vertically, reducing the footprint. At the same time, the influence of the eccentic load coused by the gravity of the rotor of the motor is reduced, and the motor is more stable.

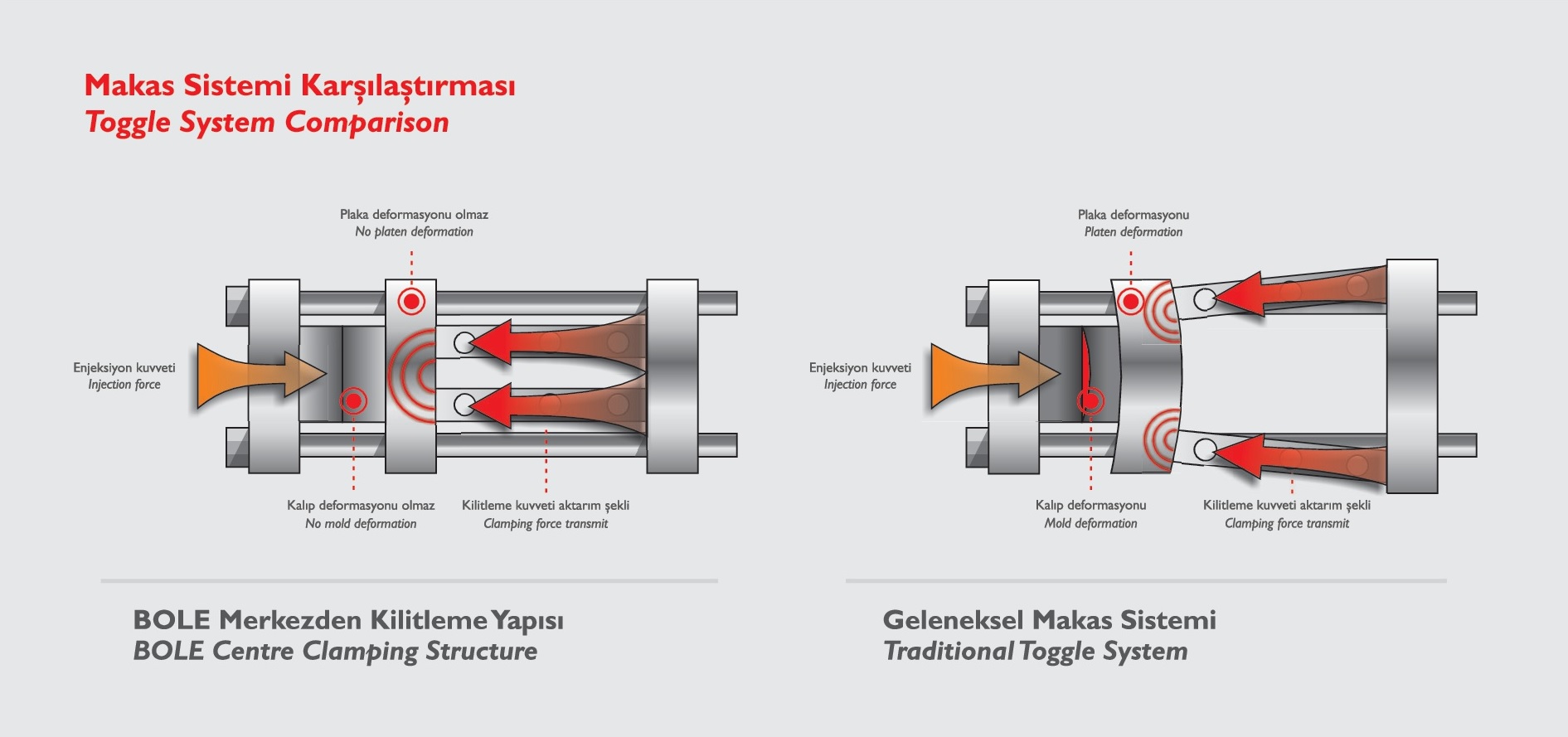

05. Fast, stable and impact-free locking system

Fast, smooth, quiet, more effective lock nut to protect tie bar and nut itself, prolong equipment lifetime.

06. Synchrınized ejection (core) movement

Simultaneous eject (core pulling) functions as standard, improve machine cycle efficiency.

07. Special injection cyclinder design

The new injection cylinder has extremely low oil return resistance and cooperates with the frame structure of the linear guide to reduce the friction of the injection part and greatly improve the control precision of the injection unit.

08. Equal stress on each teeth

Equal stress on each teeth, longer life time for locking nuts.

09. Independent oil filter and cooling system

Very compact and less space occupation. Stabilize the entire oil temperature without any other interruption, such as cycle time and other working elements.

10. Stable feding zone temperature

The temperature of the lower feed port is incorporated into the closed-loop control of the temperature unit, which improves the efficiency and accuracy of the entire injection unit. Avoiding the influence of unloading agglomeration and misalignment, the injection molding precision is low.

11. Injection pressure sensor

The injection pressure is always fed back and the injection curve allows the customer to adjust the product process more conveniently.

Other Products of the Company

See AllTrimm - Servo Injection Moulding Machine

Trimm - Servo Injection Moulding Machine

Bole Ekh Series - Injection Moulding Machine

Bole Ekh Series - Injection Moulding Machine

Bole Ekw Series - Hydraulic Servo Energy Saving Injektion Moulding Machine

Bole Ekw Series - Hydraulic Servo Energy Saving Injektion Moulding Machine

Bole Mk Series - Multiple Injection Moulding Machine

Bole Mk Series - Multiple Injection Moulding Machine

Similar Products

See AllPLASTIC ENJECTION MACHINE

Plastic Enjection Machine

Full Electric Nova5eT_360T

Negri Bossi 5Et Plastic Injection Molding Machine

HDSW

Spool Winder

PET PREFORM INJECTION MOULDING MACHINE