Emw Series 3 Axis Servo Robot

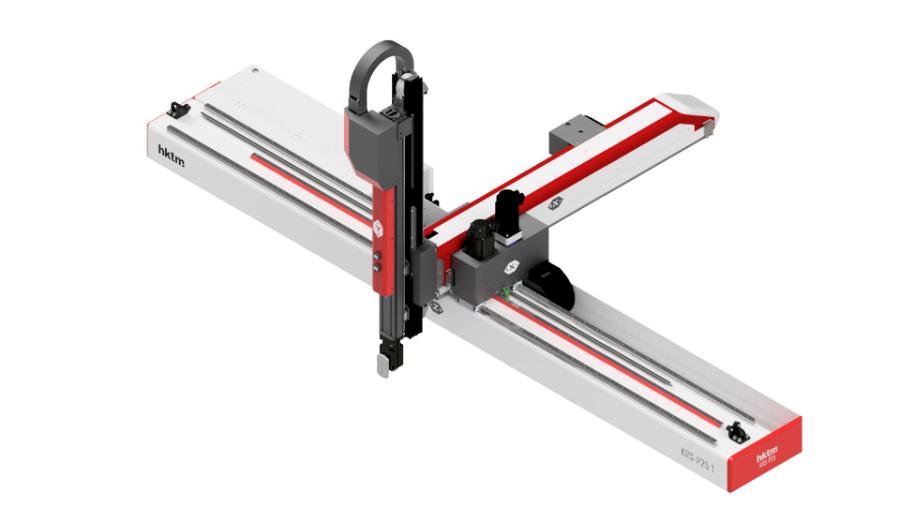

EMW Series 3 Axis Servo Robot

Category:

Robots

This product is provided by the company NOKTA PLASTİK TEK. SAN. VE TİC. LTD ŞTİ. . Please contact for more information.

Product Description

EMW Series robots can easily operate in plastic injection molding machines between 200 tons and 1600 tons.

There are single arm and double arm models.

In this series, the Z axis has a telescopic structure. We recommend working with this type of robots in places with height problems.

Robot automation system adds speed to production and reduces the cost rates in production to a certain extent.

The connection system to plastic injection molding machines is made using Euromap-12 and Euromap-67. It can also easily adapt to Far Eastern sockets in Far Eastern origin machines.

The control panel provides ease of use with its convenient interface and touch screen. It provides convenience in copying and uploading programs with USB Interface connection.

Enmair Robots are under warranty and service by Nokta Plastic Technologies with years of experience.

With the faulty product separation feature, it separates faulty products with the injection machine interface.

Multi-language option can be activated and used by the user.

With the tracking function feature, you can set the pusher values in the actual position in the injection molding machine to prevent damage to the robot arm in the mold.

With the product pick-up control feature, it is used to make arm movement in a suitable position.

With the product stacking feature, it can stack products according to the actual need.

With the arm descent delay feature, it is used to shorten and adjust the product removal time by waiting in the vertical arm.

It can leave the runner at any point on the traverse axis.

With the mold\’s range of motion feature, the robot can move freely in the mold to pick up the product.

Buzzer feature activates when the robot alarms.

Optionally, if standard I/O is not enough, additional input and output points are available.

Optionally, it is possible to make multi-axis, more functional movements and increase tolerance by selecting RV reducer and servo motor.

With the gripper rotation function, you can rotate the gripper outside and inside the mold area.

Other Products of the Company

See AllSeiii Series Servo Motor Plastic Injection Molding Machine

Seiii Series Servo Motor Plastic Injection Molding Machine

Jseii Series Two-Platen Plastic Servo Motor Injection Molding Machine

Jseii Series Two-Platen Plastic Servo Motor Injection Molding Machine

Sec Series High Speed Servo Motor Plastic Injection Molding Machine

Sec Series High Speed Servo Motor Plastic Injection Molding Machine

6 Axis Robot

6 Axis Robot

Similar Products

See AllKRS Series Robots

Robots

PLASTİK ENJEKSİYON MAKİNESİ ROBOTLARI

Plasti̇k Enjeksi̇yon Maki̇nesi̇ Robotlari

CARTESİAN ROBOT

Mw1200Ii

CARTESİAN ROBOT