PE-PP PLASTIC RECYCLING MACHINES

PE-PP PLASTIC RECYCLING MACHINES

Category:

Plastic recycling machines and technologies

This product is provided by the company NETPLASMAK MAKİNA SANAYİ TİCARET AŞ . Please contact for more information.

Product Description

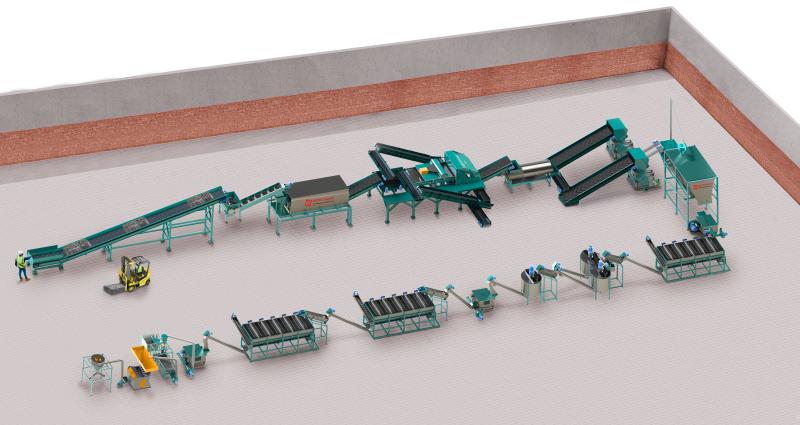

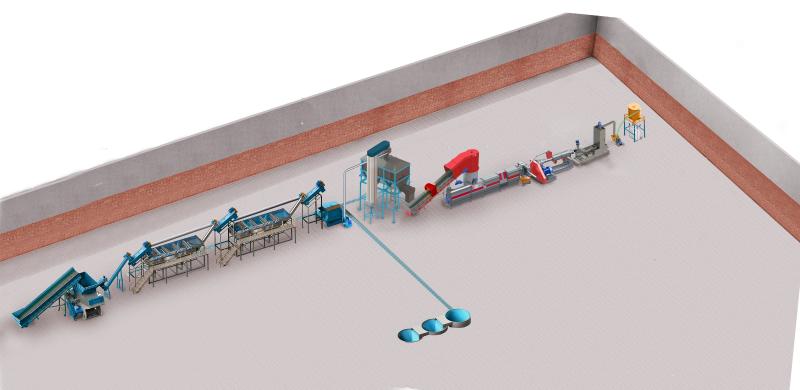

Plastic recycling lines are established to process waste plastics, such as PE, PP, LDPE, and HDPE in both soft and hard forms, and convert them into reusable raw materials. A complete recycling

line consists of two main sections. The first section includes sorting, shredding, and washing processes, while the second section involves the granulation line where the raw material is produced.

After being sorted by type, the plastics are reduced in size through shredding or crushing. These reduced plastics are then transferred to the washing-cleaning centrifuge located at the beginning

of the washing line via a suitable screw conveyor or belt conveyor. In the centrifuge, the plastics are washed through friction at high speed and are separated from contaminants (dust and soil)

and from other unwanted plastic types (such as PET and PVC) within a tank, after which they proceed to the next step—drying.

Other Products of the Company

See AllPET BOTTLE RECYCLING LINES

PET BOTTLE RECYCLING LINES

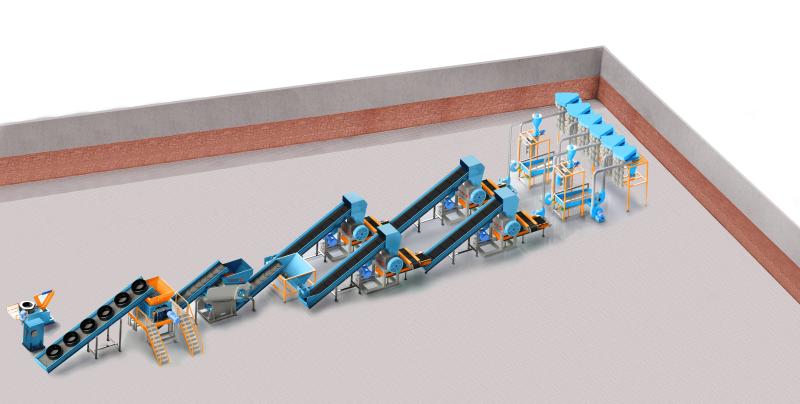

Automobile Tire Recycling Line Producer

Tire Recycling Machines

PE-PP Plastic Shredder Machine

Shredder Machine

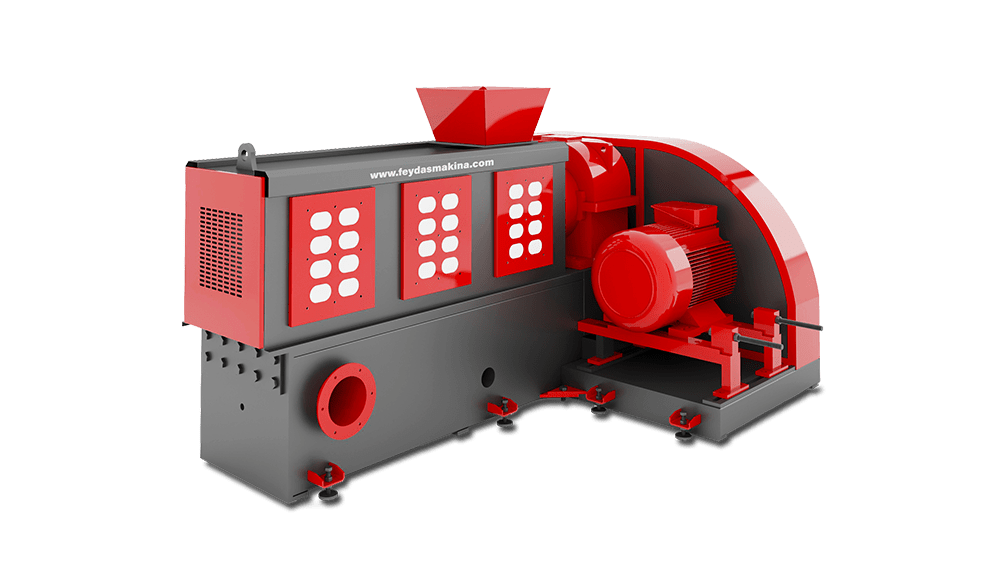

PE-PP Plastic Crusher Machine

Crusher Machine

Similar Products

See AllGXC Series

Granulator

RPS

RPS

PP PE FILM HORIZONTAL SQUEEZING MACHINE

PP PE FILM HORIZONTAL SQUEEZING MACHINE

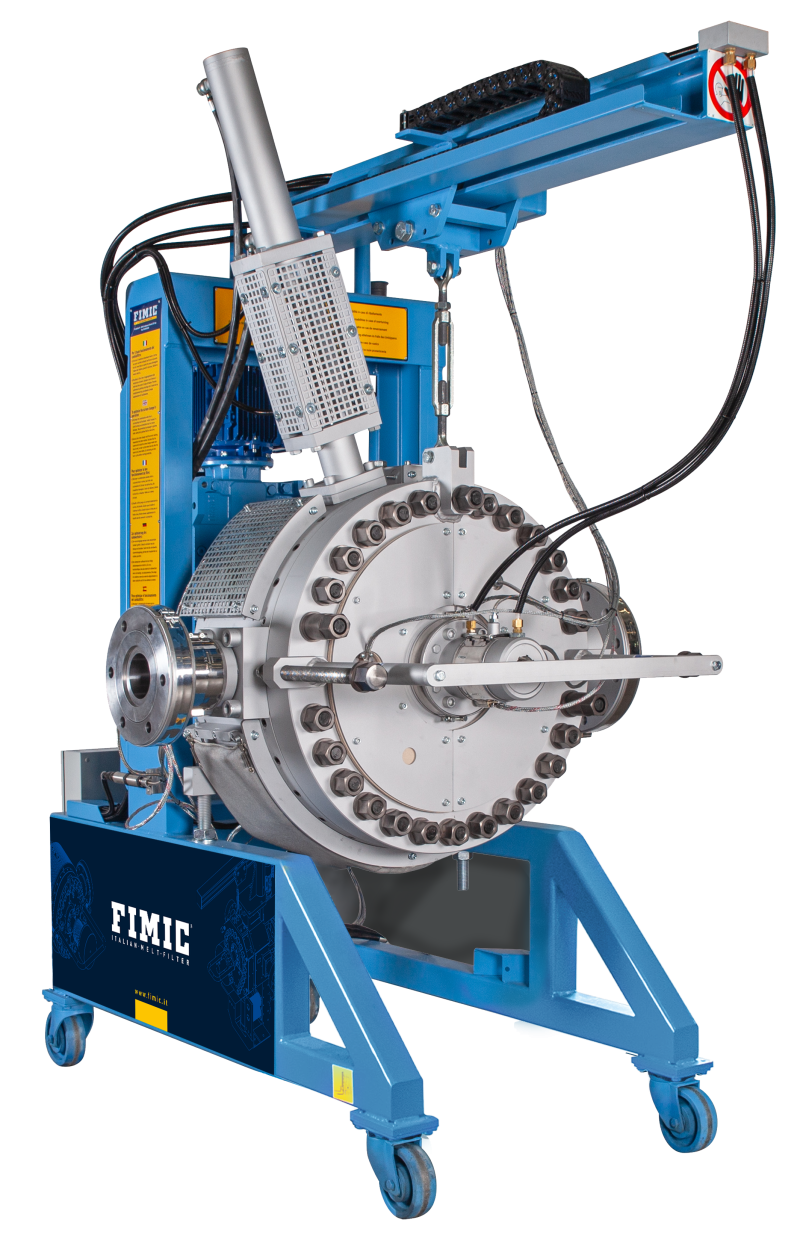

Melt Filters