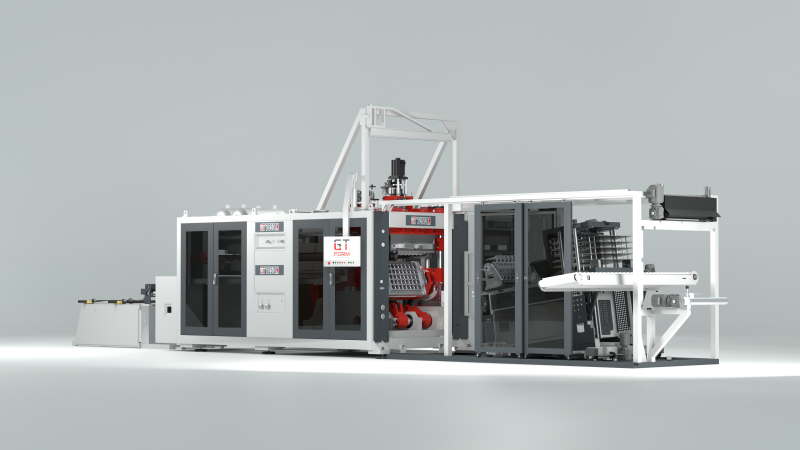

GTS900 STEEL RULE DIE THERMOFORM MACHINE

GTS900 STEEL RULE DIE THERMOFORM MACHINE

Category:

Thermoforming machines

This product is provided by the company GÜVEN TEKNİK MAKİNA KALIP SAN DIŞ TİC LTD ŞTİ . Please contact for more information.

Product Description

GTS 900 STEEL RULE CUTTING MACHINE GENERAL SPECIFICATION

High performance, easy and safe operation with high techology.

Rebust and solid machine body specially for high speed and non-stop production.

Smart speed setting ability by touchscreen.

Advanced heating system with izolated ceramic heater. NO NEED FOR PREHEATER.

Quick tool changing and smart tool locking system.

Reliable after sale service.

Latest generation of software program and touch screen operating panel.

High speed modem connection in order to facilitate after sale support.

Induvidual lubrication inlets for each bearing.Technical Specifications

Model : GTS 900

Maximum tool size : 900 * 630 mm

Pozitive stroke : 150 mm

Negative stroke : 150 mm

Production material : PP, Pet, PS, PVC, OPS

Material thickness : 1.5 mm ( Maximum ) Pet – 2.0 mm PS, OPS, PVS, PP

Lenght of the heater pan : 2300 mm

Upper heater pan power : 97 Kw

Lower heater pan power : 117 Kw

Dry cycle : 80 cycle

Vacuum pomp power : 3 kw

Air requirement ( filtered air ) : 7 bar

Electricity: 3 Phases 380 vollt 50 Hz

1. Feeding Unit

Pneumatic roll lifting unit.

Double roll lifting capacity.

Sheet entrance ceramic side heaters for sheet transport.

Nonstop unwinding system.

2. Chain & Chain Rails

Omron servo motor chain pulling system from front side.

55 Hrc heat treatment steel channel for chain transport. ( Not Aluminum !!! )

42 Hrc custom manufacturing chain.

Aluminum body with water cooling system.

Dropsa Automatic lubrication for chain rails.

Automatic sheet stretching ability.

Motorised chain rails distance adjustment ability controlling by touchscreen.

3. Heaters

Elstain brand izolated, energy saver H series ceramic heaters.

13 line standart ceramic heaters.

2360 x 935 mm dimensions heater trays. No need for pre heaters.

Hig precission temperature controling with the horizontal and vertical cross heater design.

Close timbered ceramic heaters with short gaps.

23 zones controlled upper pan.

13 zones controlled lower pan.

Thermocouple PID temperature controoling system.

Sheet melting laser sensors.

Upper heater total power: 97 Kw standart.

Lower heater total power: 117 Kw standart

Anti-vibration heater trays lineers mowing design from bottom.

4. Forming Station

4 columns, each columns are 100 mm heavy duty shafts.

Servo motor driven plug assist system.

Servo motor driven, clamping force 60 ton.

Max. Tool size 630mm x 900 mm.

Max. Stroke up and down 150 mm.

Motorised up and down height adjustment ability controlled by plc.

Lineer system clamping frame design.

Automatic lubrication for clamping frame.

Induvidiual lubrication feeding for each beraing.

Needle type heavy duty bearings.

Flow rate controlling system for cooling water.

Faster tool change, quick mould locking and automatic centering.

Upper block take up system with support piston.

5. Punching Station

4 columns, each columns are 100 mm heavy duty shafts.

Servo motor driven, clamping force 60 ton.

Two movable platen ( upward and downward ) driven by Servo motors.

Max. Stroke up and down 150 mm.

Motorised high precission punching system for upper platen.

Induvidiual lubrication feeding for each beraing.

Needle type heavy duty bearings.

Upper block take up system with support piston. ( to adjust paralelling between of the platens )

6. Cutting Station

4 columns, each columns are 100 mm heavy duty shafts.

Servo motor driven, clamping force 60 ton.

Two movable platen ( upward and downward ) driven by Servo motors.

High precisse heating system for cutting knife controlling by touchscreen.

Motorised X-Y position adjustment with lineer scale.

Quick knife fixing.

Cutting platens with minimal deflection to increase knife life.

Induvidiual lubrication feeding for each beraing.

Needle type heavy duty bearings.

Upper block take up system with support piston. ( to adjust paralelling between of the platens )

7. Servo motorised Upward Stacking System

-Lower cost with high efficiency.

-A-B stacking.

-High accuracy linner guides.

8. A-B-C Upward 3 Axess Robot Stacking System

-High speed, high efficiency.

-A-B-C Stacking.

-Quick tool change.

-Solid robot body.

-Ina brand lineer systems.

-Sew Eurodrive planet gearboxes.

9. Waste Roller Unit

Sencronized waste roller with the tork control.

Quich waste discharge system.

Waste overload warning sensor.

Other Products of the Company

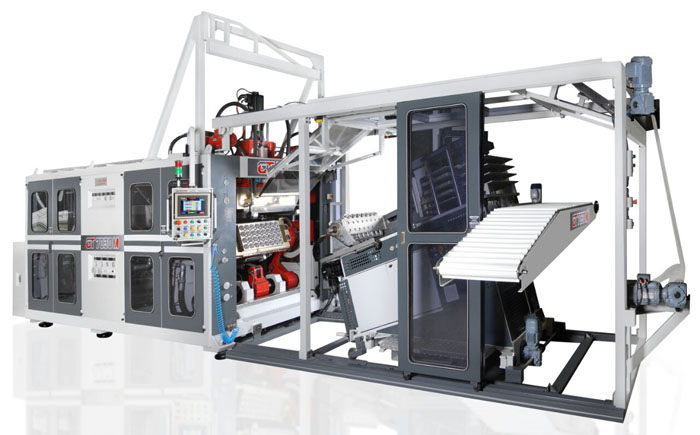

See AllGT7050 M TILT BED THERMOFORM MACHINE

GT7050 M TILT BED THERMOFORM MACHINE

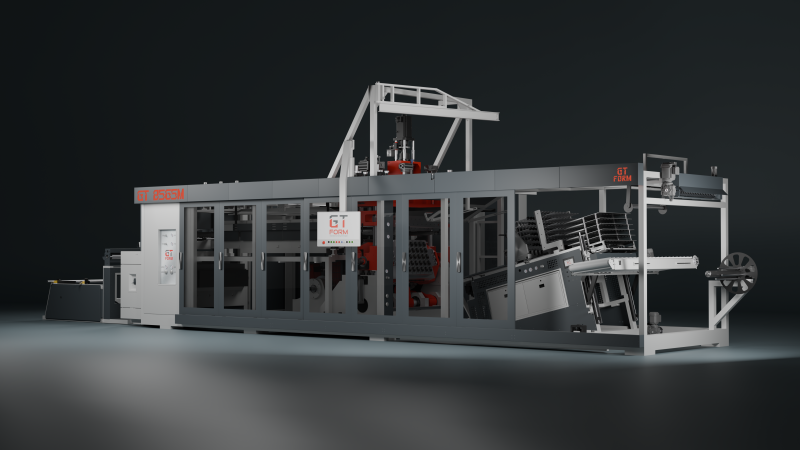

GTS1000 STEEL RULE DIE THERMOFORM MACHINE

GTS1000 STEEL RULE DIE THERMOFORM MACHINE

GT7030 M TILT BED THERMOFORM MACHINE

GT7030 M TILT BED THERMOFORM MACHINE

GT8565 M TILT BED THERMOFORM MACHINE

GT8565 M TILT BED THERMOFORM MACHINE

Similar Products

See AllCup Making Machine

Thermoforming Machine With Tilting Mold

Vacuum Forming Machine

Vacuum Forming Machine

THERMOFORMİNG

THERMOFORMİNG VACUUM MACHİNE

Air pressure forming machine