HVAC Whole system injection Molds

Plastic Injection Mold

Category:

Plastic molding equipment and machines

This product is provided by the company TAIZHOU HENYA MOLD CO., LTD . Please contact for more information.

Product Description

HVAC System Housing Injection Mold – Mold Description

1. Application & Function

This mold is designed for producing plastic housings and structural components of automotive HVAC systems, including air ducts, blower covers, evaporator housings, and heater cores. The parts require stable dimensional accuracy, low warpage, and excellent sealing performance to ensure long-term reliability of the HVAC system in real driving conditions.

2. Mold Design Highlights

Multi-cavity or single-cavity layout optimized according to part size and annual volume

Multiple sliders, lifters and inserts to form deep ribs, undercuts and complex air channels

Optimized parting line and sealing surfaces to reduce flash and post-trimming work

Rigid mold structure to minimize deformation during high-pressure molding cycles

3. Steel & Mold Base

Mold steel selected according to required tool life and resin type (typically H13 / 1.2343 or equivalent for core and cavity)

Mold base made from pre-hardened steel for stability and easy maintenance

All critical components with material certificates and hardness reports available upon request

4. Runner, Gate & Cooling System

Hot runner or semi-hot runner system available to reduce material waste and improve filling balance

Gate type and position (e.g., edge gate, submarine gate, valve gate) optimized to control flow marks, weld lines and warpage

High-efficiency cooling circuits placed close to thick areas and ribs to reduce cycle time and keep part dimensions stable

5. Venting & Part Quality

Sufficient vents and vacuum options at flow ends and rib intersections to prevent burn marks and short shots

Special attention to sealing surfaces and clip areas to ensure proper assembly with mating HVAC components

Dimensional and appearance check fixtures available to support stable mass production

6. Process Capability & Validation

Mold designed to meet OEM/aftermarket requirements for dimensional accuracy and air-tightness

T1 mold trial with full process window study, including packing, cooling and demolding optimization

Capability study (e.g., Cpk on key dimensions) and sample inspection reports can be provided according to customer requirements

7. Production & Service Support

Mold suitable for standard injection molding machines with automatic ejection and, if required, robotic part picking

Clear maintenance guidelines and spare parts list supplied with each mold

Engineering support available for DFM review, tooling optimization and on-site/remote start-up assistance

Other Products of the Company

See AllDurable Plastic Chair & Stool Injection Mold for Indoor & Outdoor Seating

Plastic Chair & Stool Injection Mold

High-Performance Plastic Crate & Pallet Injection Mold for Logistics & Storage Solutions

Plastic Crate & Pallet Injection Mold

Custom Insert Injection Mold for Metal–Plastic and Multi-Material Parts

Insert Injection Mold

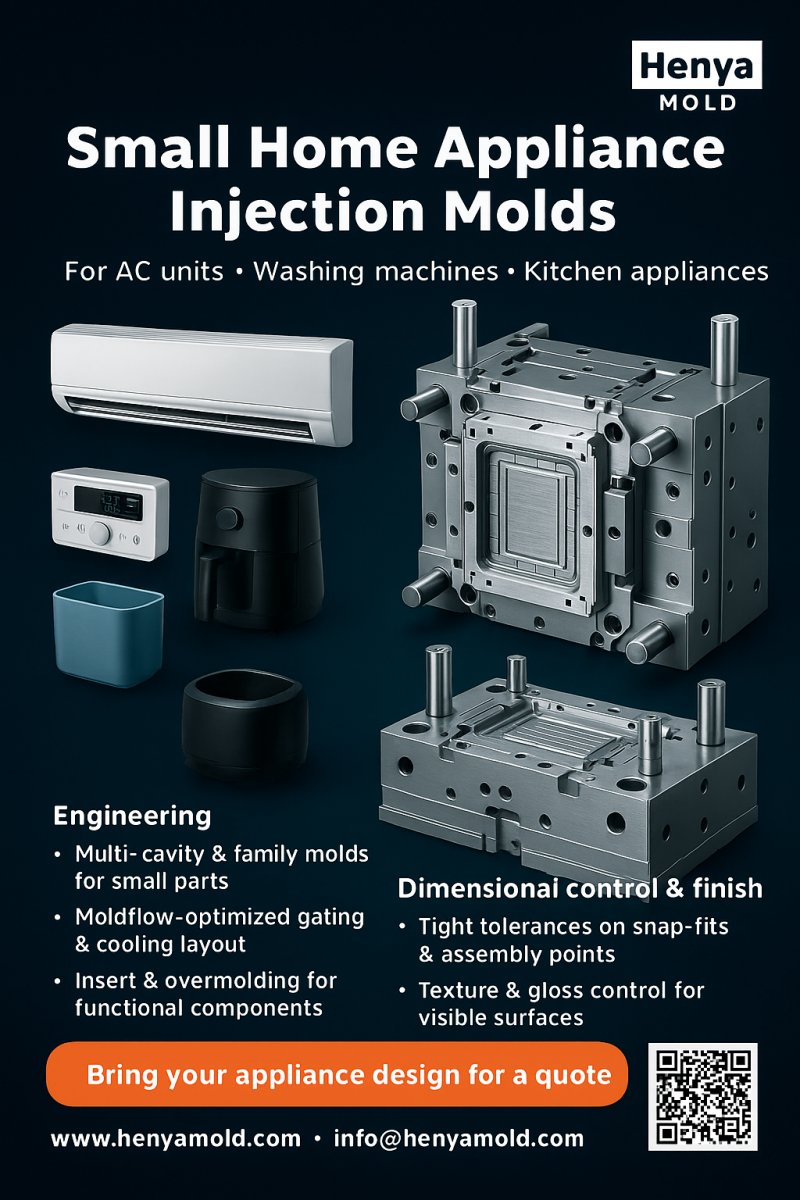

High-Precision Home Appliance Plastic Injection Mold for Covers & Structural Parts

Home Appliance Injection Mold

Similar Products

See AllAutomotive Front Bumper Mold

Car bumper mould design and manufacture

High-Precision Automotive Headlamp Lens & Housing Injection Mold for OEM & Aftermarket Programs