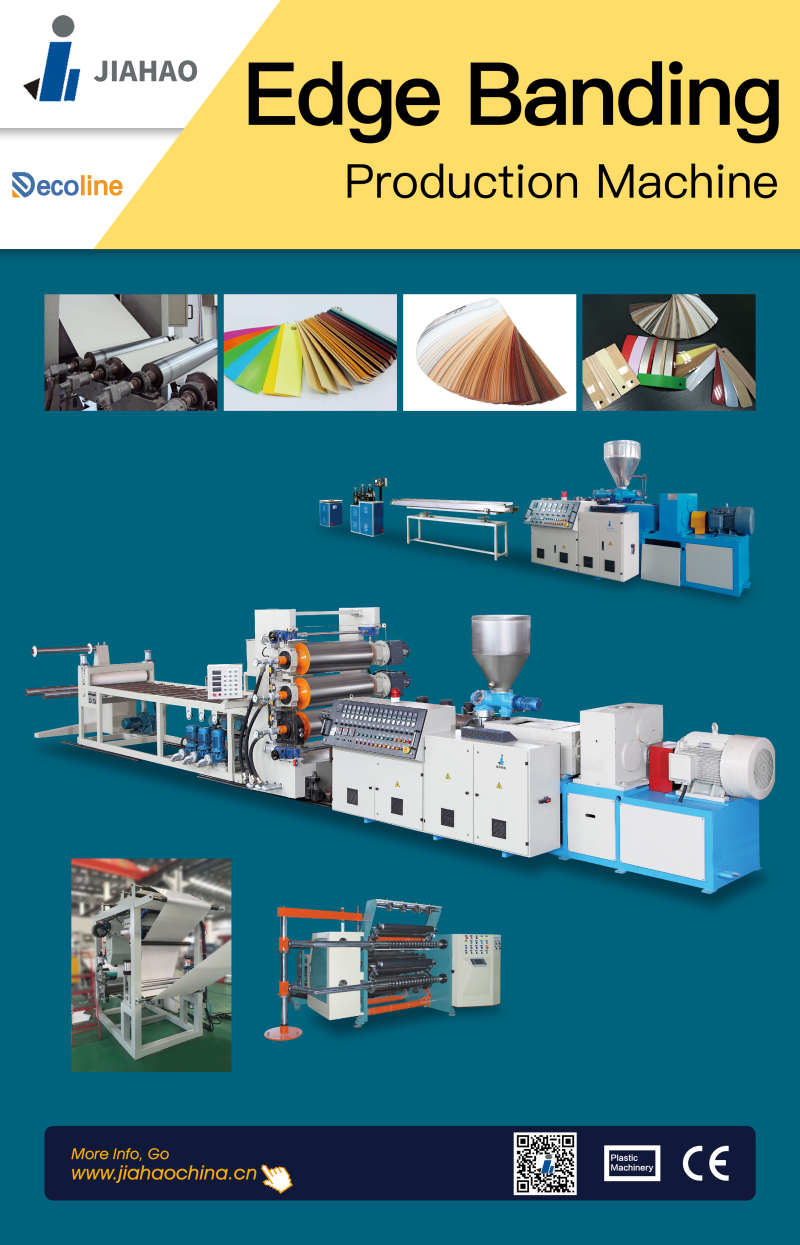

PVC EDGE BANDING PRODUCTION LINE

Automatic PVC Edge Banding Production Line Jiahao Machinery Custom Size Support

Category:

Extruders

This product is provided by the company ANHUI DECOLINE INTELLIGENT TECHNOLOGY CO., LTD. . Please contact for more information.

Product Description

Applications of PVC Edge Banding:

1. Furniture Industry: PVC edge banding is widely used for edge treatment of office furniture, cabinets, and wardrobes, providing an aesthetically pleasing look and physical protection.

2. Construction and Decoration: Suitable for edge treatment of door frames, window frames, and interior decorative strips, enhancing the durability and aesthetics of building components.

3. Commercial Facilities: Used for shop decoration and commercial display cases, ensuring neat and durable edges and enhancing the overall aesthetics of commercial spaces.

4. Automotive Interiors: Used for interior decoration of automobiles and RVs, enhancing the wear resistance of edges.

PVC/ABS edge banding extrusion production lines can be divided into two categories based on the production process: edge banding sheet production lines and edge banding production lines.

1. Edge Banding Production Process:

Edge banding is extruded using a twin-screw extruder, and then processed through a die, a three-roll calender, traction, cooling, and winding processes. The sheet is then slit into strips.

This process is suitable for producing single-size, high-volume products, increasing output and saving labor.

2. There are two production processes for strip-shaped edge sealing strips:

(1) One-step powder process: Twin-screw extrusion production line.

This process is simple, convenient, and low-cost.

(2) Two-step granulation process:

– Twin-screw granulation production line

– Single-screw extrusion production line

This process provides better plasticization of raw materials and higher product quality.

We will recommend the most suitable production line based on your needs and provide the most cost-effective solution.

Other Products of the Company

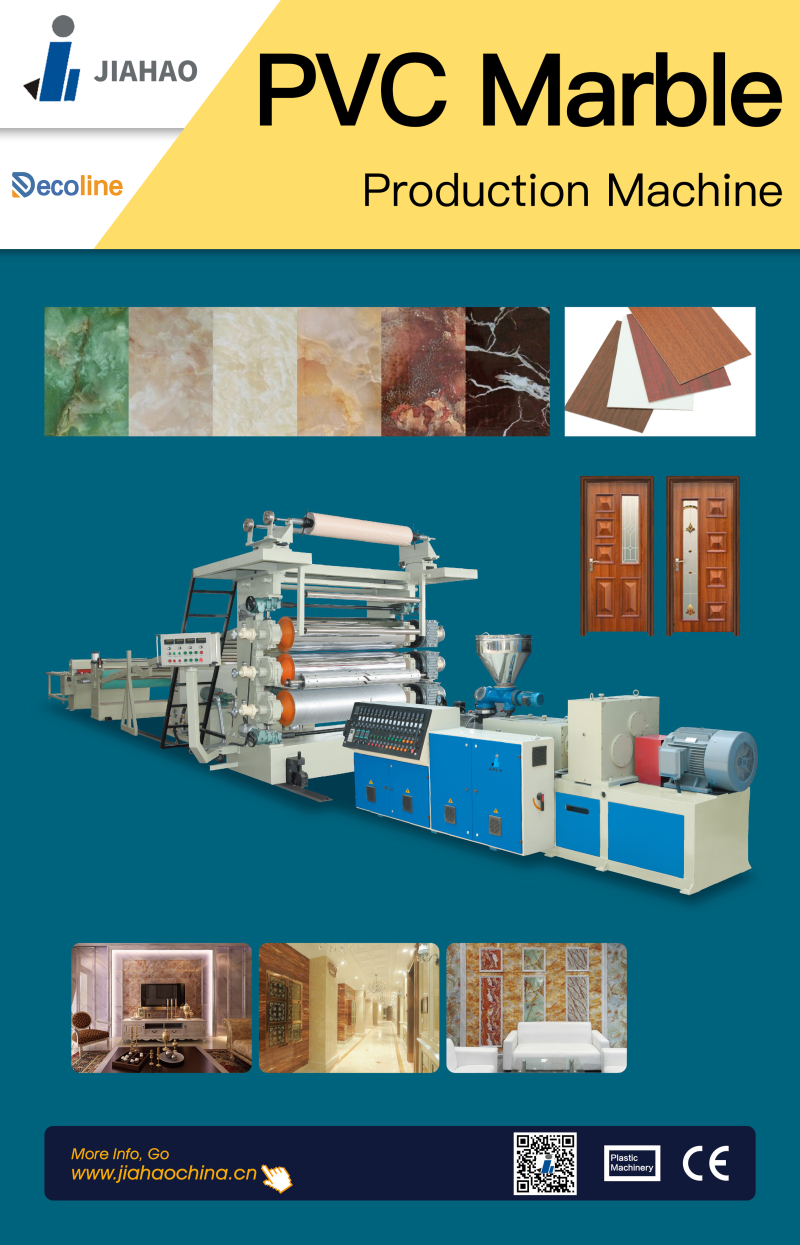

See AllHigh Efficiency PVC Marble Sheet Extrusion Line Jiahao Machinery CE Certified

PVC Marble Sheet Extrusion Line

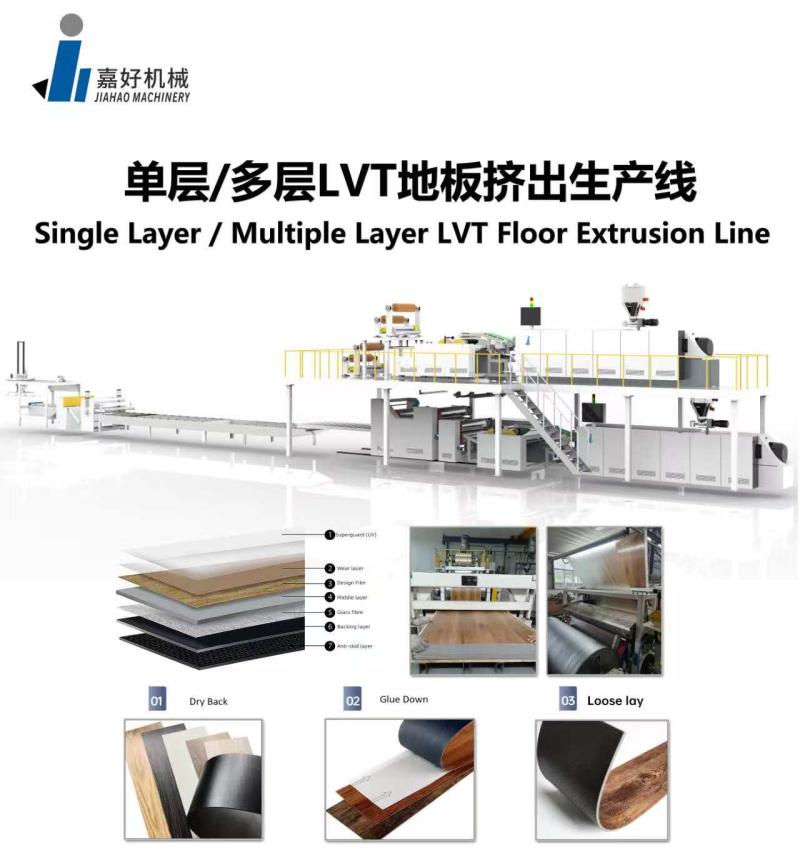

LVT Flooring Production Line - Jiahao Machinery: Integrated Production, Wear-Resistant Layer Lamination, Stable and Low Consumption, After-Sales Guarantee

LVT FLOORING PRODUCTION LINE

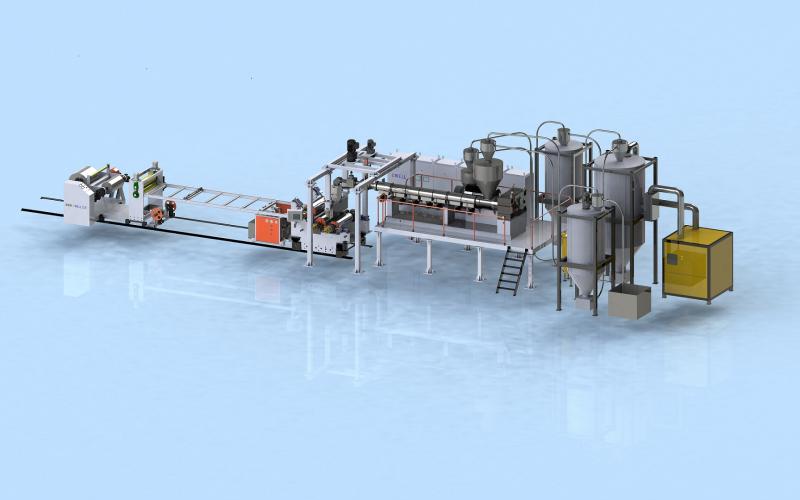

WPC Wood Plastic Flooring Extrusion Line Jiahao CE Certified Stable Customizable

WPC PROFILE PRODUCTION LINE

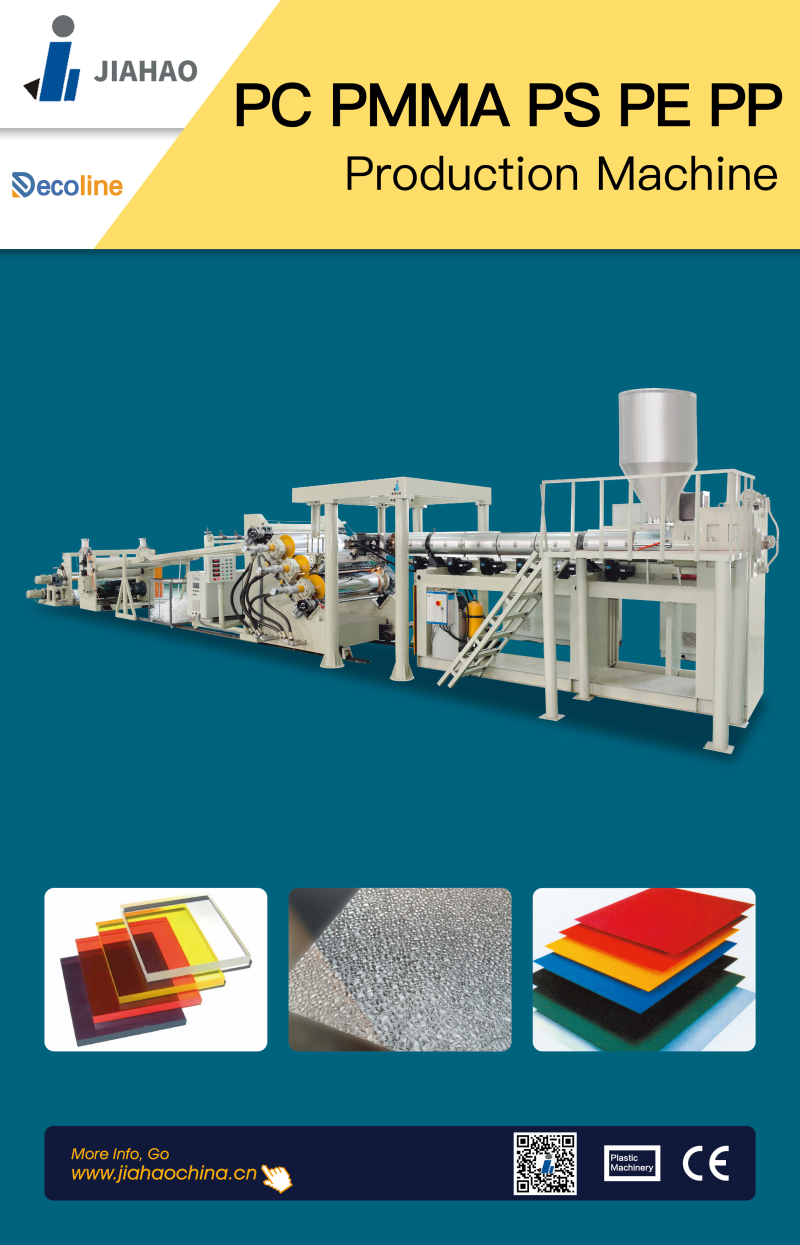

Multi-Material Plastic Extrusion Line Jiahao CE Certified PC PMMA PS PE PP Compatible

PC PMMA PS PE PP production machine

Similar Products

See AllMulti-Material Plastic Extrusion Line Jiahao CE Certified PC PMMA PS PE PP Compatible

PC PMMA PS PE PP production machine

PLASTIK PIPE EXTRUDER

PLASTIC EXTRUDER LINE

Pipe Extrusion Line

PE/PP/MPP Water/Gas Supply and Power Threading Pipe Extrusion Line(20-1200 mm)

PET sheet extrusion