MGB-PPS-1300

P.P. Sheet Extrusion Line

Category:

Extruders

This product is provided by the company MING JILEE ENTERPRISE CO. LTD. . Please contact for more information.

Product Description

1. Stand of extruding unit can be movable forward and backward which will increase convenience on controlling.

2 Screw is special mixing function and hi-plasticizing capability design, it incorporates with European imported static mixer to ensure melting of resins, homogeneous color and increase on extruding output.

3. T-die is special double throttling design to enable adjustment for sheet thickness to be more accurate.

4. Temperature control uses SCR system, tolerance of temperature for that is±1?, this may precisely control plasticizing processes, sheet thickness, flatness and neatness.

5. Embossing station is operated lifted up and pulled down freely. During operation, this will provide more choices for both thick sheet and thin sheet and to upgrade product quality.

6. Sheet thickness control uses screw and pressing roller two-way adjustment, this may control the sheet thickness precisely.

7. Sheet length is control by PLC and driving by servo motor to get accurate size.

8. Electric control box: it completely uses high class and qualified accessories and it is of save space design, operation for that is simple and convenient.

Other Products of the Company

See AllAir Cooling Type Recycling & Pelleting Machine

MGB-RP-120

PP/PE Zipper Profile Extrusion Lin

MGB-ZIP-45

P.P Blown Film (Tubular) Extrusion Line

MGPP-65

MGR-MINIROLL-1600

Air Bubble / EPE Coreless Rewinding Machine

Similar Products

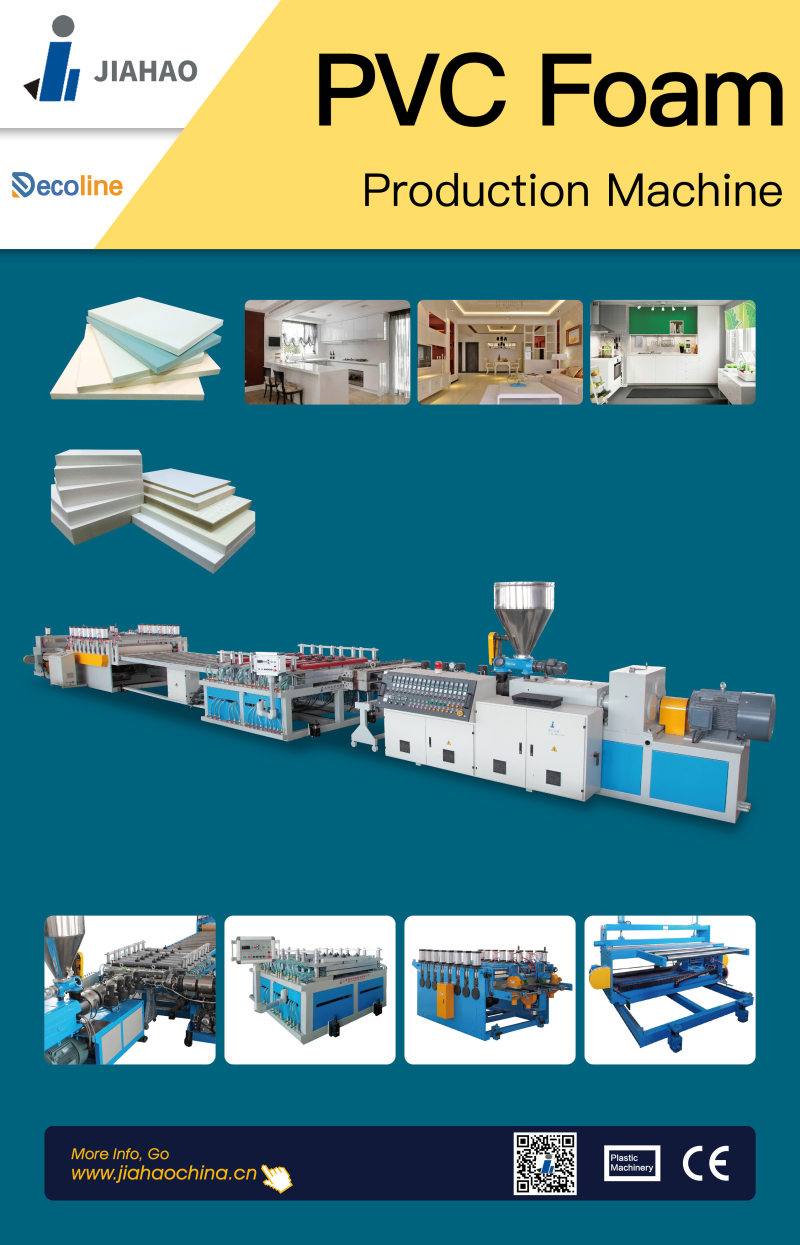

See AllMulti-sheet compatible PVC extrusion production line for furniture boards, cabinet boards, and foam boards. High output, energy saving, and after-sales guarantee.

PVC furniture board and cabinet board production line

UPVC roofing sheet machine

UPVC roofing sheet machine

Strand pelletizer

Stellite cutting rotor

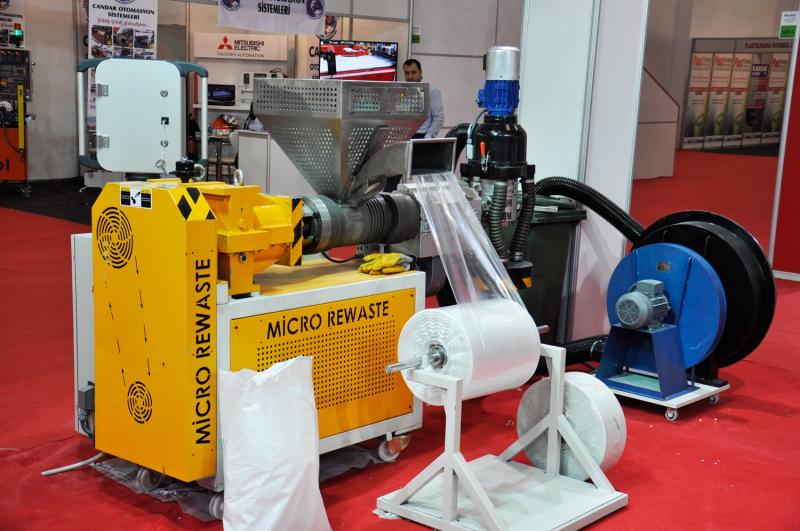

Micro Rewaste Recycling Machine