Machine Vision

Smart Optical Inspection & Geometry Measurement

Category:

Extruders

This product is provided by the company EXTRUDER MAKİNA ÜRETİM A.Ş. . Please contact for more information.

Product Description

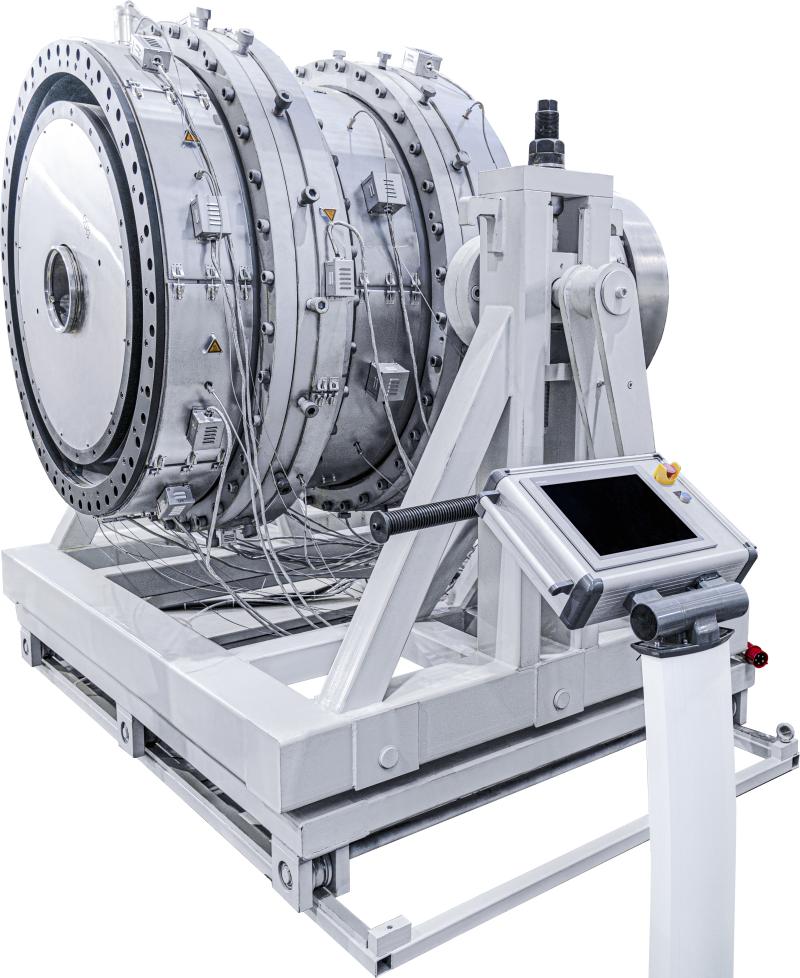

The Machine Vision system operates with VisionApp 360, where all sensors are fully calibrated and synchronized. Calibration is performed easily using a dedicated calibration object, ensuring precise alignment and unified accuracy across every sensor. After the calibration phase is completed, the entire outer geometry of the profile is analyzed as a single, coherent structure through uniVision software or the customer’s own evaluation platform. The system offers measurement tolerances between ±0.05 mm and ±0.3 mm, supports production speeds up to 12.5 m/min, performs 300 measurements per second and requires a short warm-up period of approximately 15 minutes to stabilize temperature and profile alignment. It is compatible with multiple profile types on the same extrusion line and detects a wide variety of defects, such as dimensional deviations, inclusions, scratches, dents, cavities, missing or misaligned seals, edge ripple, incorrect wall thickness and faulty internal webs. The software environment combines VisionApp 360 with uniVision under a single interface, allowing all sensors and cameras to be managed through one control unit. The system offers a user-friendly setup, fast parameter adjustment and full customization according to customer-specific requirements.

Other Products of the Company

See AllExtruder For Plastic & Rubber

Extruder

2,3 and 5 rolls Calenders

Calender

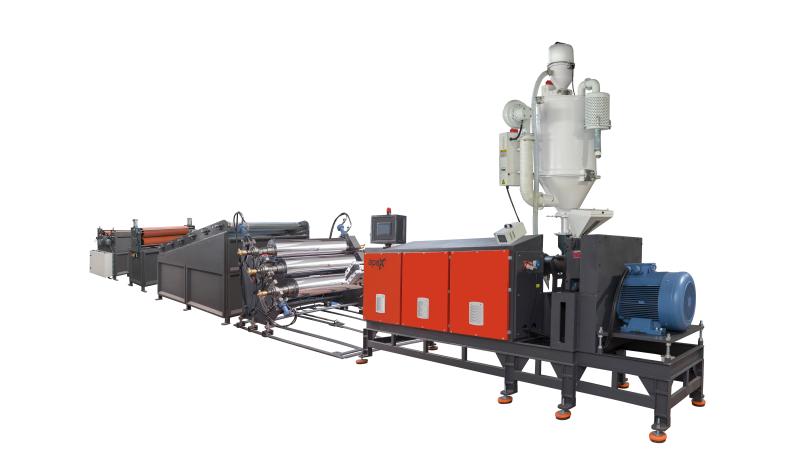

Fim & Sheet Extrusion Line

Sheet production line

Single Screw Extruders with Co-Extrusion

Single-screw Extruder

Similar Products

See AllDIE HEAD

EXTRUSION DIE HEAD

Conical twin screw extruder

Conical twin screw extruder

High Precision Plastic Door and Window Production Line Jiahao Manufacturer Supply

PLASTIC DOOR AND WINDOW PRODUCTION LINE

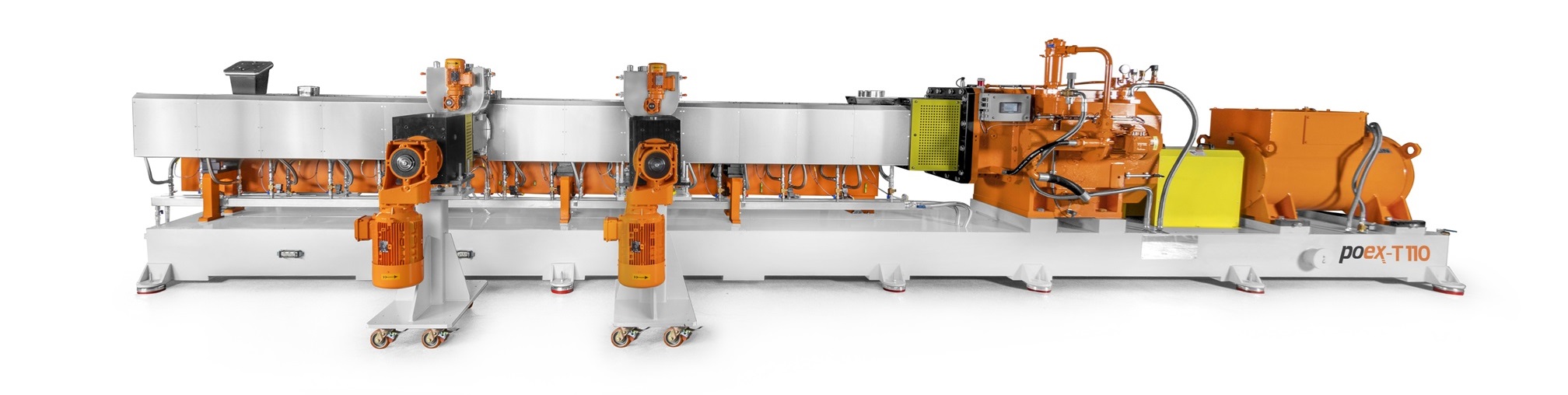

co-rotating twin screw extruder