Aircraft Product Mold

APM

Category:

Plastic molding equipment and machines

This product is provided by the company FANSTAR (DONGGUAN) SMART TECHNOLOGY CO., LTD. . Please contact for more information.

Product Description

Fanstar Injection Mold Manufacturer: Focus on High-Quality Injection Mold Services for Aircraft Interior Plastic Parts

In the modern aviation industry system, aircraft interior plastic parts have long transcended the single attribute of "decorative accessories" - they are not only "comfortable carriers" that enhance passengers' flight experience, shaping the visual aesthetics and tactile texture of the cabin, but also "key components" that ensure flight safety. They need to maintain structural stability and reliable performance under harsh environments such as high-altitude low pressure, temperature fluctuations, and long-term high-frequency use. Relying on years of technical accumulation in the field of precision molds, Fanstar Injection Mold Manufacturer focuses on the segmented needs of aircraft interior plastic parts, with "millimeter-level precision" and "aviation-grade standards" as the core, providing global aviation customers with full-process high-quality services from mold design, R&D to processing and manufacturing. It is committed to endowing every detail of aircraft interiors with the dual guarantee of "exquisite appearance" and "solid core".

In the high-threshold field of aviation molds, Fanstar has built a profound technical barrier and experience system. We deeply understand the special requirements of aircraft interior plastic parts: in terms of materials, it is necessary to adapt to aviation-grade modified plastics (such as high-temperature resistant PA66, flame-retardant PC/ABS, lightweight PEEK, etc.), balancing strength, toughness and environmental compliance; in terms of process, it is necessary to cope with the molding challenges of complex structures (such as integrated armrest shells, special-shaped air outlets, precision fasteners); in terms of precision, it is necessary to meet the dimensional tolerance of ±0.02mm to ensure seamless assembly between components and long-term use stability. To this end, we have established a "full-process strict quality control system": from the early stage of working with customers to optimize product structure (DFM manufacturability analysis) to avoid risks in mold processing and plastic part molding; to using advanced equipment such as five-axis machining centers and high-precision EDM machines for processing core mold components to ensure the precision and surface finish of mold cavities and cores; and then to simulating the entire process of filling, holding pressure and cooling through mold flow analysis (Moldflow) to optimize process parameters, ensuring that there are no shrinkage marks, bubbles, warpage and other defects after plastic part molding. Finally, the perfect balance between "lightweight design" and "high-strength durability" is achieved, meeting the extreme requirements of the aviation industry for interior parts.

In the actual processing link, Fanstar overcomes the manufacturing difficulties of aircraft interior plastic parts with advanced injection molding technology and professional team strength. We have introduced closed-loop control injection molding machines, combined with customized temperature control systems and precision metering devices, to realize real-time control of injection pressure, speed and temperature. This ensures that aviation-grade plastics are fully melted and uniformly filled, and finally presents a smooth, delicate and flawless plastic part surface, which can meet the visual and tactile standards of aircraft interiors without additional secondary processing. At the same time, our core team is composed of senior engineers and technical craftsmen with more than 15 years of experience in aviation molds. They are not only proficient in the mold design logic of aircraft interior parts, but also can provide customized solutions based on the personalized needs of different customers (such as differences between passenger aircraft and cargo aircraft interiors, functional distinctions between business class and economy class). Whether it is the precision small part manufacturing experience extended from the pen mold field, or the complex structure handling capabilities accumulated in the electromechanical shell mold field, they can be seamlessly transformed and applied to aviation interior mold projects, ensuring that each set of molds can accurately match the customer's product positioning and production needs.

In addition to high-quality mold processing services, Fanstar is also committed to providing "full-life cycle technical support" for aviation customers. In the early stage of the project, we will send a technical team to conduct in-depth docking with customers, participate in technical discussions in the product design stage, and provide mold feasibility suggestions to help customers shorten the R&D cycle; after mold delivery, we provide free technical training and installation and commissioning guidance to assist customers in quickly starting production; in the later cooperation, we have established a "24-hour rapid response mechanism". For the mold maintenance and process optimization problems encountered by customers in mass production, we provide solutions in the first time to ensure the continuity of customer production. Relying on this all-round service system, we have established long-term and stable cooperative relationships with a number of domestic and foreign airlines (such as major domestic airlines, regional feeder airlines) and first-tier suppliers of aviation components (such as aviation interior system integrators). We have participated in the interior upgrading of many civil airliners and business jets and the R&D projects of new aircraft models. With the delivery record of "zero quality accidents" and "exceeding expected cooperation efficiency", we have won high trust from customers and a good reputation in the industry.

Choosing Fanstar Injection Mold Manufacturer means choosing "aviation-grade quality standards" and "partner-style reliable services". We always treat each set of molds with the rigorous attitude of the aviation industry and pursue our own value based on the success of customers. In the future, we will continue to invest in the R&D of aviation mold technology, explore lighter, more environmentally friendly and higher-performance mold solutions, and look forward to working with more customers in the aviation field to jointly promote the improvement of aircraft interior manufacturing standards, making every flight more valuable due to a safer, more comfortable and more exquisite interior experience.

Other Products of the Company

See AllSimilar Products

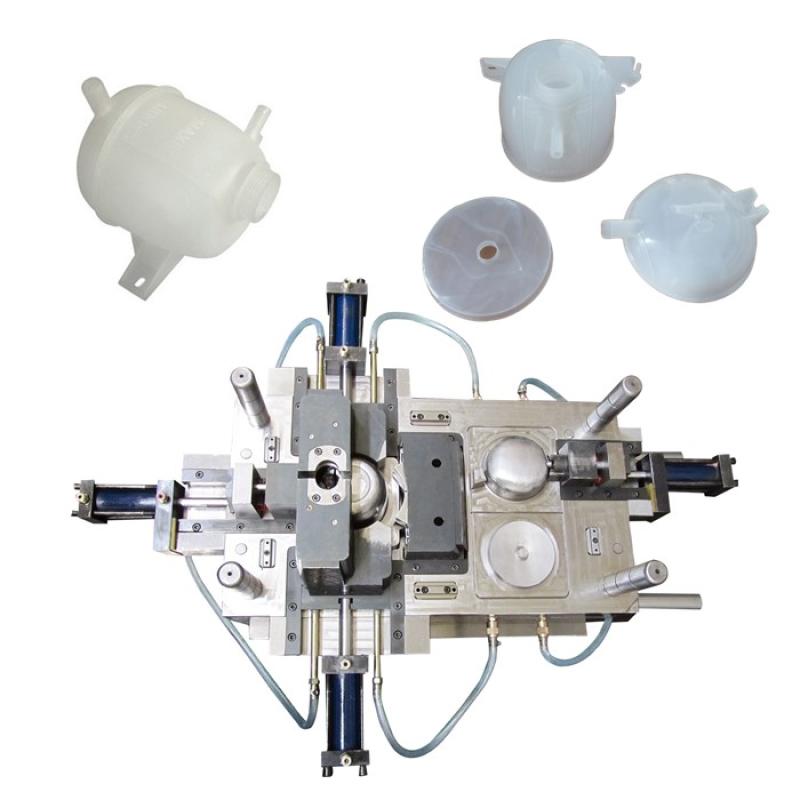

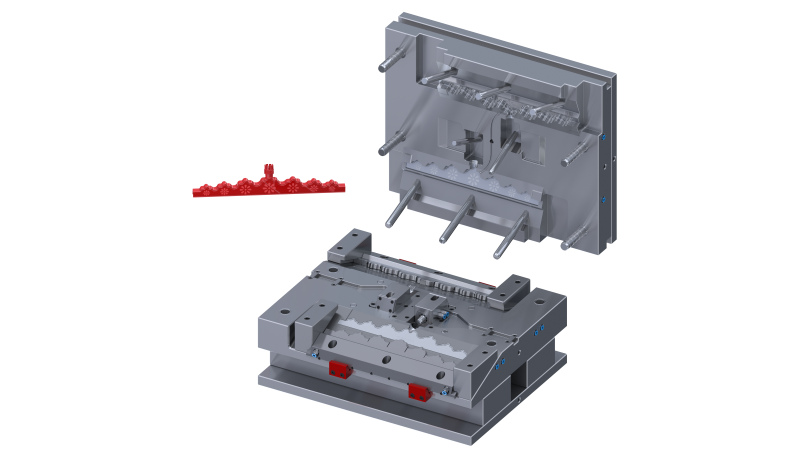

See AllSoğutma Suyu Rezervuarı Genleşme Tankı Enjeksiyon Kalıp Üreticisi

Mold For Coolant Reservoir Expansion Tank

PLASTIC INJECTION MOLD

FLOOR SQUEEGEE MOLD

Shampoo Flip top cap moulds-Injection

Shampoo Flip top cap moulds

Flip top cap mould with IMC-Injection