Electrical Swith Panel Mold

ESPM

Category:

Plastic molding equipment and machines

This product is provided by the company FANSTAR (DONGGUAN) SMART TECHNOLOGY CO., LTD. . Please contact for more information.

Product Description

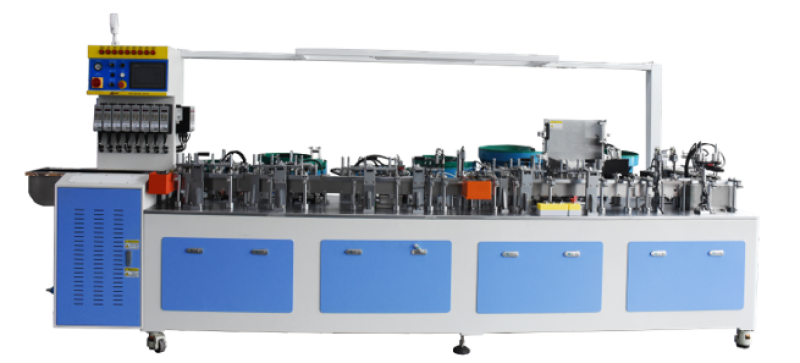

Fanstar Electrical Switch Panel Mold

The Fanstar Electrical Switch Panel Mold is a high-precision injection molding tool designed exclusively for the mass production of electrical switch panels. As a core component in the electrical equipment manufacturing industry, it integrates advanced mold design concepts and strict quality control standards, catering to the functional and safety requirements of electrical switch panels—such as structural durability, electrical insulation, and dimensional accuracy.

Core Technical Advantages

High-Precision Molding for Reliable PerformanceCrafted from premium mold steel (e.g., S136, H13), the mold boasts exceptional wear resistance and thermal stability. Its refined cavity structure and precision machining ensure that each switch panel maintains consistent dimensional tolerance (controlled within ±0.03mm) and a smooth surface free of burrs. This not only guarantees a tight fit with internal electrical components but also enhances the panel’s mechanical strength, preventing deformation or damage during installation and long-term use.

Safety-Oriented Design for ComplianceThe mold is engineered to accommodate flame-retardant, high-insulation plastic materials (e.g., PC, ABS) that meet international electrical safety standards (such as IEC, UL). It features a rational venting system to eliminate air bubbles in the molding process, ensuring the final product’s electrical insulation performance and flame-retardant effect. Additionally, the mold’s design supports the integration of safety structures like anti-shock edges and dust-proof seals, helping manufacturers produce switch panels that pass strict safety certifications.

Efficient & Customizable for Mass ProductionEquipped with an optimized cooling system, the mold shortens the plastic solidification cycle to 20-30 seconds, significantly improving production efficiency. It is fully compatible with automatic injection molding lines, enabling continuous mass production with an output of 800-1200 panels per hour. The mold also supports customization of panel sizes (e.g., single-gang, multi-gang), surface finishes (matte, glossy), and mounting hole positions, adapting to diverse application scenarios such as residential, commercial, and industrial electrical systems.

Application & Brand Value

This mold is an ideal production solution for electrical equipment manufacturers specializing in switch panels. It inherits Fanstar’s commitment to precision and reliability in industrial mold manufacturing, ensuring stable product quality and low defect rates. By using this mold, manufacturers can efficiently produce high-quality electrical switch panels that balance safety, durability, and aesthetics, enhancing their competitiveness in the global electrical equipment market. Moreover, the mold’s long service life (up to 1 million cycles) and low maintenance costs reduce long-term operational expenses, delivering sustainable economic benefits for enterprises.

Other Products of the Company

See AllSimilar Products

See AllPlastic Injection Mould

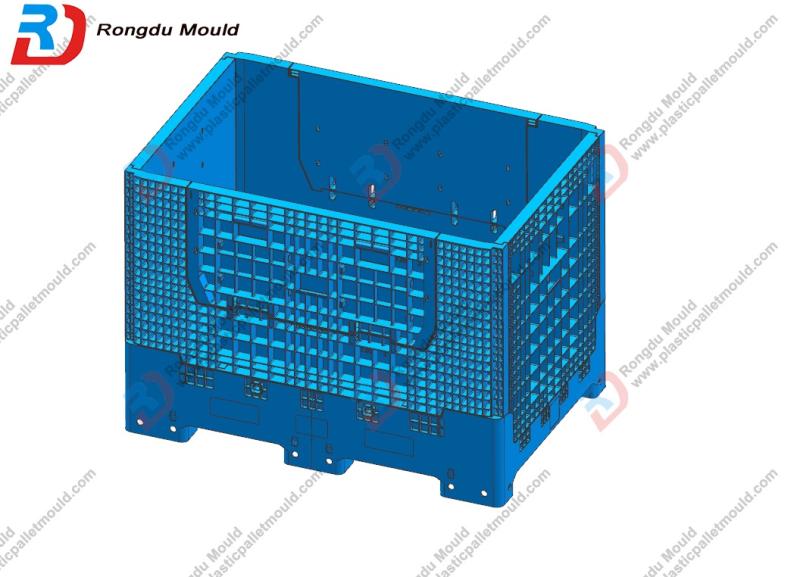

Plastic Foldable Pallet Box Injection Mould

EPS batch pre-expander

pre-expander

plate stacking mould

plate stacking mould

Restaurant supplies mold