| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

ÇAĞDAŞ ÇAĞLI KÖKBİR İTHALAT İHRACAT

ATATÜRK MAH. ÇEVREYOLU CAD. NO: 76/8G A BLOK 8ERSAN SANAYİ SİTESİ / LÜLEBURGAZ / KIRKLARELİ / TÜRKİYE

|

Contact Info: +90 505 369 0436

|

Hall: 11A

Stand: 11A-143A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

We are proud of being an approved solution partner for the polymer laboratories and manufacturers of the powder coat and plastics sectors. KÖK BİR Import Export; was established in Istanbul in 2013. Our initial aim was to supply complete polymer processing machines, their spare parts and quality control test-analysis equipment to its customers from different sectors. In the following years; our activities focused on the polymer R&D laboratories, for which we improved our activities by manufacturing parts & complete processing machines and test-analysis equipment, not just supplying them. Our customer portfolio consists of a wide spectrum, from private companies to public institutions and universities. In the recent years; we continued to improve our activities and expertise in accordance with the needs of the sectoral market. We started to manufacture the worn/deformed parts of the industrial polymer process mechines and powder coat grinding machines, of which the worn parts have to be renewed regarding to their running/maintenance time. Following our service; the feedback, we received from our customers were very precious, important and motivating. We decreased the dependency of our customers to specific companies and their agenda. This outcome made our customers save their money and time. These advantages made us be a preferred, referred and recommended solution partner in the sectoral market. We are 100% Turkish company and RTX abbreviation in product codes of KÖKBİR means ROOTEX , which is derived from English translation of our brand name. Despite our short history, we are proud of our references, which is an outcome of our principles and discipline during our service, we provide our customers. It will be understood that the source of our pride is the eligibility in our list of references. Please visit our References page in our web site, whereas the list consists of the important and well-known companies of Turkish Industry. As a result of our - continuously improvement, - reached & approved level of expertise, - improved business opportunities and - economic conditions; we upgraded our targets. Our new aim is to level up our company to the export platform and to respond the needs of the foreign companies and institutions in the foreign markets, as the same in Turkish market. Our first step is to serve the customers in the markets of our neighbor countries and following the countries around the region, whereas our long-term strategic target is to make KÖK BİR a global preferred brand. We are proud of being a trusted company, which is sought and preferred in the sector, asked for its recommendations in local market, which we start to expand to international markets. Thanks to our solution partners, which are contributing our feeling of this pride.

Our SINGLE SCREW EXTRUDER models RTX-S12, 16, 18, 22 & 25 are products, which are designed and preferred for the production of plate/pipe etc. sampling of blown or cast films, 3D filament production in Turkish market. Our TWIN SCREW EXTRUDER models RTX-T12, 16, 18, 22 & 25 are products, which are preferred for R&D purposes in the polymer sector by the polymer and powder coat producers in Turkish market. TWIN SCREW EXTRUDERs are used mainly in the R&D labs of the universities and manufacturers of different sectors. It is very important to know how and how much the final products are affected physically & chemically by the use of some specific raw materials: - Which add different and important values on the final product, but have a high cost and difficult to supply, - Which reduce the costs of the final product. The main purpose is to determine and observe how much economic return and benefits will be added on the final products by the use of some specific raw materials. ROOTEX TWIN SCREW EXTRUDERs are the key polymer processing machines of the R&D laboratories of the factories for an economic way of operation, by saving unnecessary loss of material, cancelling stop-start operations for protype/sample products and saving time. ROOTEX TWIN SCREW EXTRUDERs for the labs can be designed in any required L/D ratio. ROOTEX TWIN SCREW EXTRUDERs can also be operated in higher specific temperature values, which is needed in some polymer processes (PEI, PEEK etc.) as 420°C max., (which can not be reached by most of the manufacturers) and can be operated in the required temperature value as much as required. ROOTEX TWIN SCREW EXTRUDERs have can be equipped with the options of gravitational/volume liquid feeding and atmospheric or vacuum gas venting via different connection ports.

Our RTX-PX is to prepare test samples by keeping in the standard molds to form as required, both increasing the temperature to the melting point of polymer materials and applying high press power. High temperature accuracy and press power make RTX-PX a high-performance equipment. It was designed in accordance with the safety rules for the user. Regarding customer demand, we can manufacture between 5 to 30 tons. Since the heating and cooling tables of our presses are separate, you can put your sample molds, which you have removed under heating and under pressure, between the cooling jaws just below the heating table for rapid cooling and re-pressurize in a cold environment.

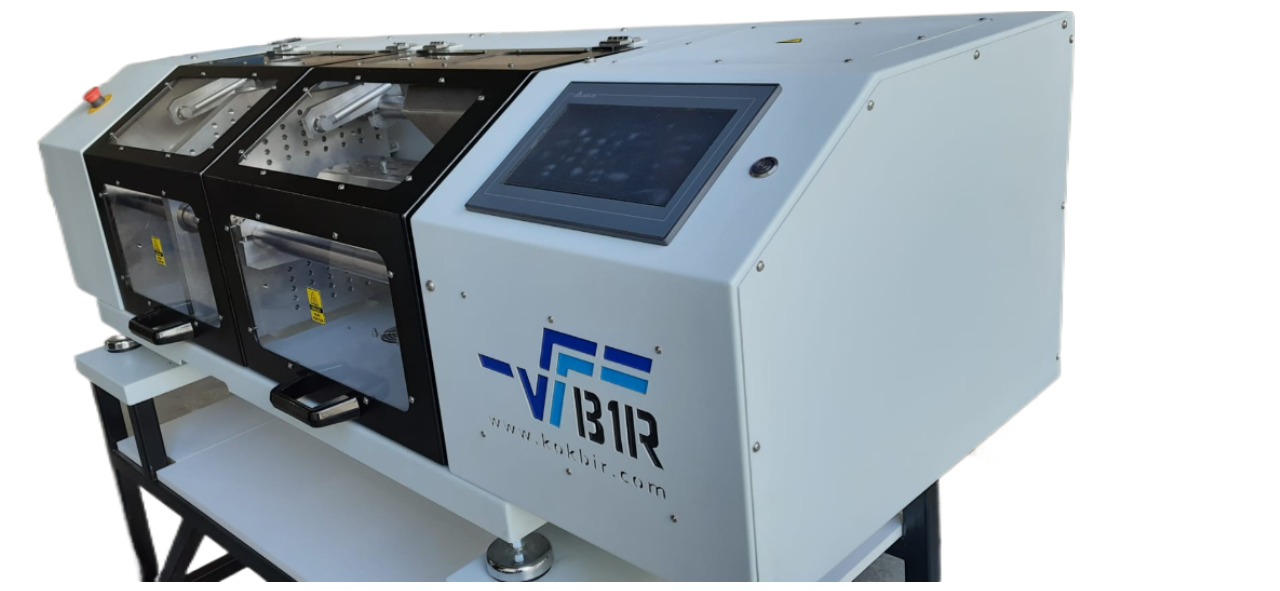

Our RTX-M40 Melt Mixer can mix all kinds of granule and powder type of polymer material with other type of organic or inorganic raw material in granule, powder or liquid forms at the required temperature value and make a homogeneous mixed melt form of polymer. Polymer in melted form can be poured into the required molds and pressed. Test samples can be prepared. It can be broken in shredding/crushing machines after it cools down and can again be injected into molds by using a laboratory injection processing machine. RTX-M40 Melt Mixer is designed with a wide range of temperature scale for operations and different type of geometrical forms of design screws for the manufacturers and factories which use PVC, PP, PE, PA, PLA, PET, EPDM and other types of polymer raw materials. What s New (Torque Rheometer Feature Added): As a result of our improvement studies on the device for a long time, we added on our RTX-M40 melt mixer the Torque Rheometer measuring feature, as of the beginning of 2021. Our RTX-M40 melt mixer can measure and calculate with the software, developed by our engineers, which you can download to any computer you are using. Now it is possible to both make homogeneous mixtures and get Torque Rheometer results with the RTX-M40.

KÖKBİR designed shredders are small scale (laboratory type) plastic crushing machine that you can easily use in mixer, press, injection, extruder outputs, which is also commonly used in recycling works Our shredders can be operated easily and user friendly, without any mechanical or electronic based failures for many years...

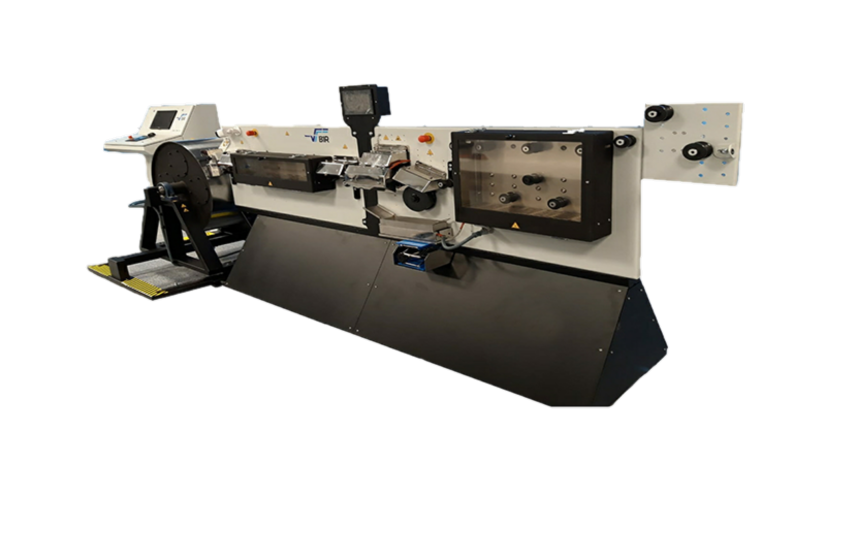

Pre-impregnated fabrics (prepreg) are high-tech materials produced by absorbing thermoset and/or thermoplastic-based matrix materials into fiber-based reinforcement materials at controlled rates and homogeneously. The intense interest in prepreg materials, which has become a type of material needed by many different sectors such as aviation, defense, automotive and wind today, has enabled our company to start working on the production of prepreg production systems as of 2018. As KÖKBİR, we are proud of designing, developing and delivering our first laboratory type of prepreg production system (not only a machine, a complete configured system), which we manufactured mostly domestic systems and materials, but by 100% Turkish engineering. The fact that the prepreg materials have a wide range depending on the raw material and usage areas causes the systems we produce to be shaped according to customer demands (custom/tailor made machines). We are happy to offer suitable engineering solutions for you/your projects and the best we can, to design and manufacture systems/machines regarding your technical specifications, requirements and demands, as mentioned below: - Reinforcement type (such as Carbon, Glass, Aramid, Natural Fiber Reinforcements, etc.) - Resin Type (Thermoset or Thermoplastic) - Product Features (such as Width, Capacity, Environmental factors, etc.) - Line Features (Solvented or Hot-melt)

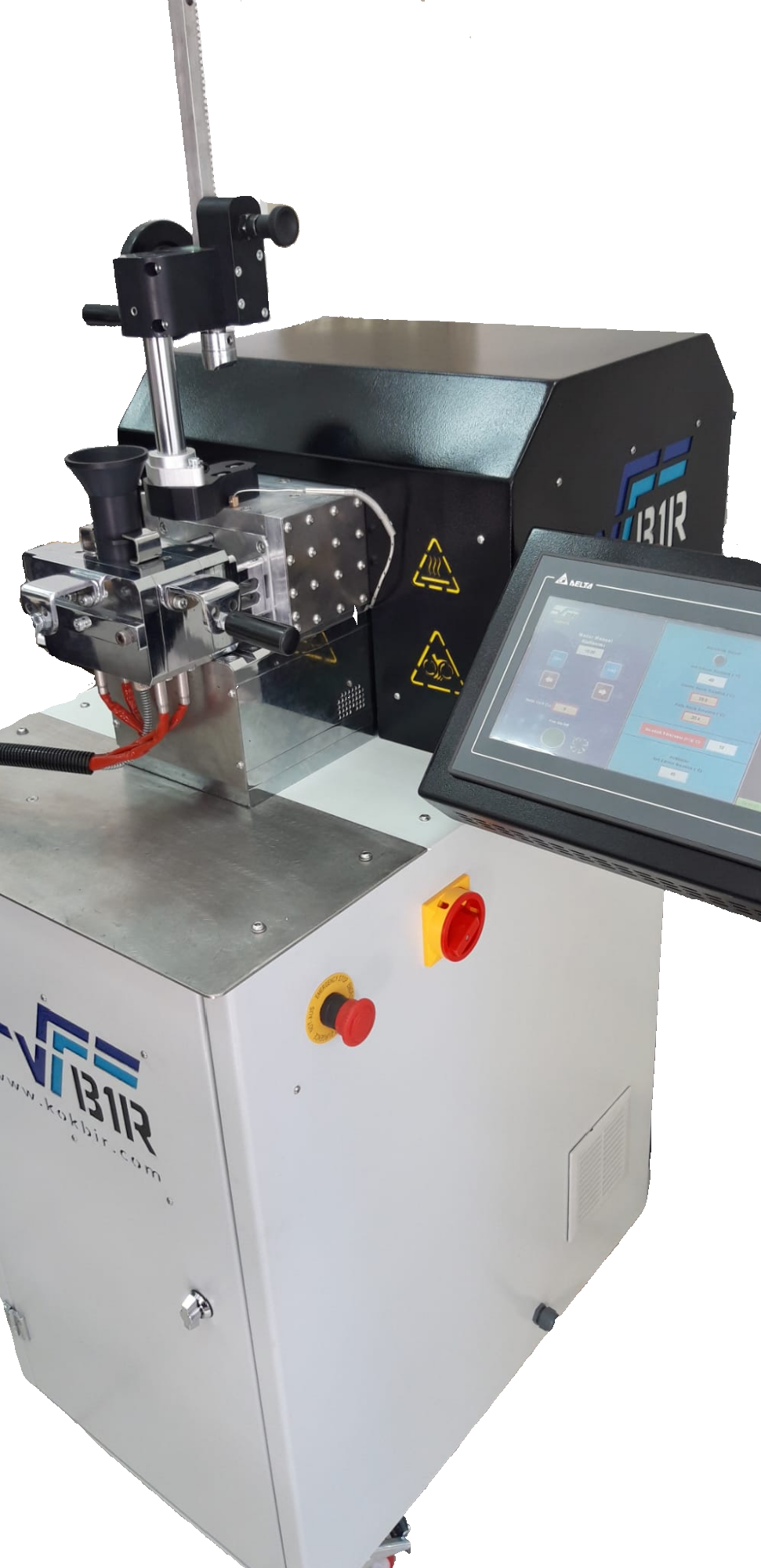

RTX-E20 benchtop injection molding machine is designed to solve the problems of research & university laboratories. Color charts, tensile / compression and impact charpy test samples can be easily manufactured by using RTX-20 benchtop injection molding machine. With the precision of the stepper motors and the power of the planetary gearbox, with the automation integrated into the machine; RTX-E20 allows you to work either automatically or manually.

MFI tester is used to measure melt flow index, melt volume flow rate and melt mass flow rate (MFI, MVR, MFR) of thermoplastic materials according to GB 3682, ISO 1133, ASTMD 1238, ASTMD 3364, DIN 53735, UNI 640, JJGB 78-94 standards. It is possible to measure the melt flow indexes of PA, PE, PP, PS and ABS materials, including PC materials with high melting temperature. Our MFI device, which is PLC controlled and has an automatic sample cutting knife, can perform manual or automatic tests thanks to its 7 inch LCD touch screen and sensitive encoder. The temperature range is from room temperature up to 400 ºC. It is possible to retrieve PDF data from the results via USB or to connect the device to a PC for storage on the PC. In addition, our new MFI model, which can measure IV (intrinsic viscosity) for PET very precisely, has started to take its place in the market.

Gel Time Analyzer is a test equipment used for the detection of gel time of especially resin based polymer products and powder coat, glue in liquid form etc. in specific required temperature conditions. Our user friendly Gel Time Test Analyzer is certified by TSE and in the market with an attractive price.

Microtomes are used to take samples as sections, profiles from the surface of the polymer as a film, granule or final product. Our microtome devices can cut thinner than a strand of a human hair from the polymers to examine. Samples as sections between 0.05 and 100 µm can be taken. It is easy and user friendly to operate our device, which also has a high sensitivity property. We manufacture manual, servo and digitally controlled microtomes regarding to customer requirements and demands.

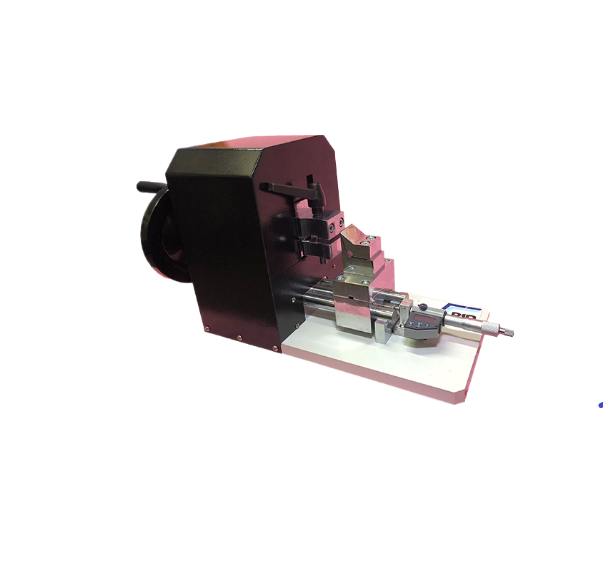

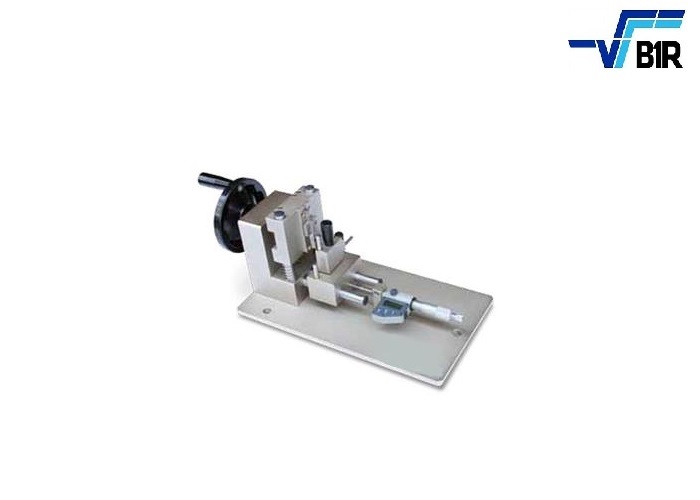

Designed to notch samples for impact resilience. Izod, Charpy and Tensile impact test methods and procedures are used. The linear knife avoids overheating and consequent stresses during the operation.

No represented companies found.

- KÖKBİR

TR

TR