| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

FAVORİ GRUP PLASTİK VE MAKİNE SAN. TİC. A.Ş.

SELAHADDİN EYYUBİ MAH. 1629. SOK. NO: 3/3 / ESENYURT / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 407 0607

|

Hall: 8

Stand: 824

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

In 2010, we have come to life with a young team who is experienced in the plastic industry and has adopted the principle of unconditional customer satisfaction. Established with the purpose of meeting all the machinery and hardware requirements of the sector, Favori Group aims to provide permanent solutions by analyzing the current and future needs of the plastic industry with the efficiency-oriented service concept. Favori Group, which has meticulously selected European, the Far East and Turkish origin brands in its product range, work with the manufacturers who can offer the service to the plastics industry in the fastest way with technology. New Generation Service, Your New Generation Supplier

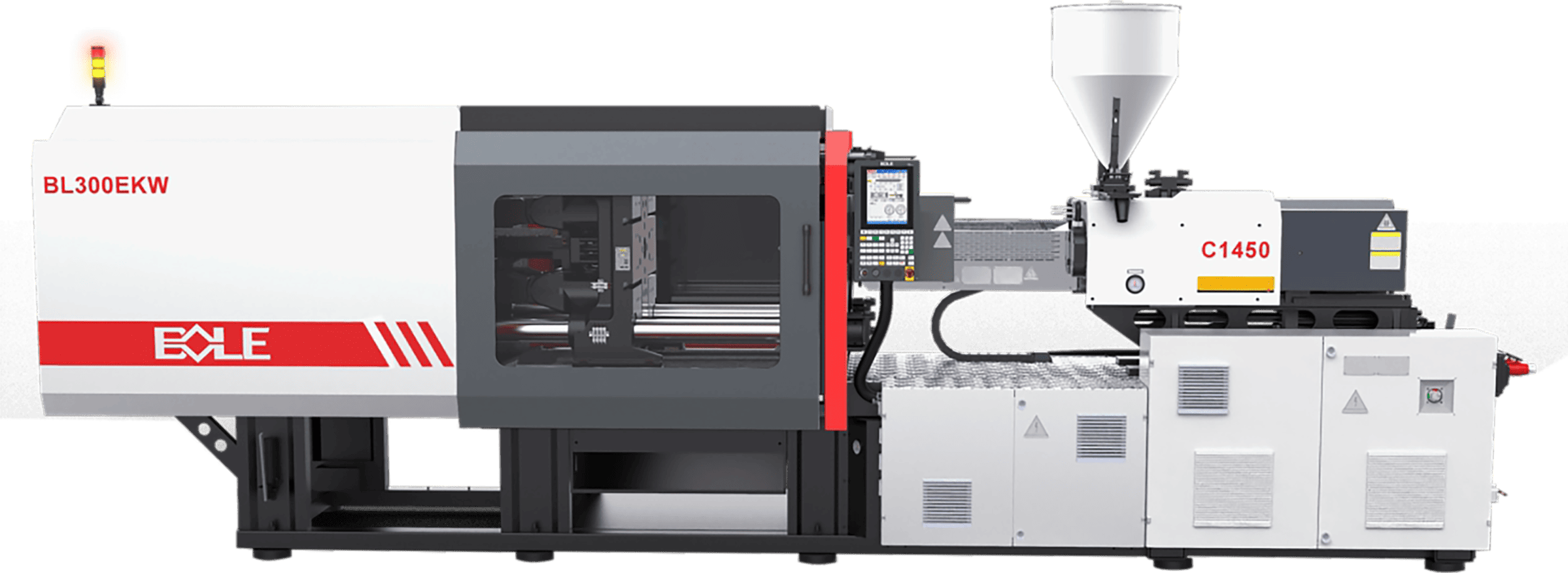

Traditional clamping unit type used in injection molding machines for many year. Platens have both T-slots and bolt holes for setup the mold. In this way, ease of use is ensured as needed. Stylish looking, easy to use automatic lubrication system. Designed by Turkish engineers. Reliable production with Ultra-high rigid platens. Accurace, rigid production with hydraulic blocks and the entire hydraulic system designed by Turkish engineers and produced in Türkiye. Hydraulic parts from famous internatioanal manufacturers, ensure machine with reliable performance. High precision hydraulic block and valve system designed by Turkish engineers. Automatic lubrication system designed and developed by Turkish engineers, providing long-lasting use and high working efficiency. The central lock clamping structure provides bigger opening & ejector stroke and provide install larger mold opportunity. Repetitive positioning accuracy of molf opening&closing: ±1 mm Product weight repetitive accuracy ≤ %0,5 Less possibility of flash and save flash trim process Hydraulic block and valve system designed by Turkish engineers, working with high efficiency and precision Electrical cabinet comform to GB,CE, UL, KCS or other safety standards EST controller is standard

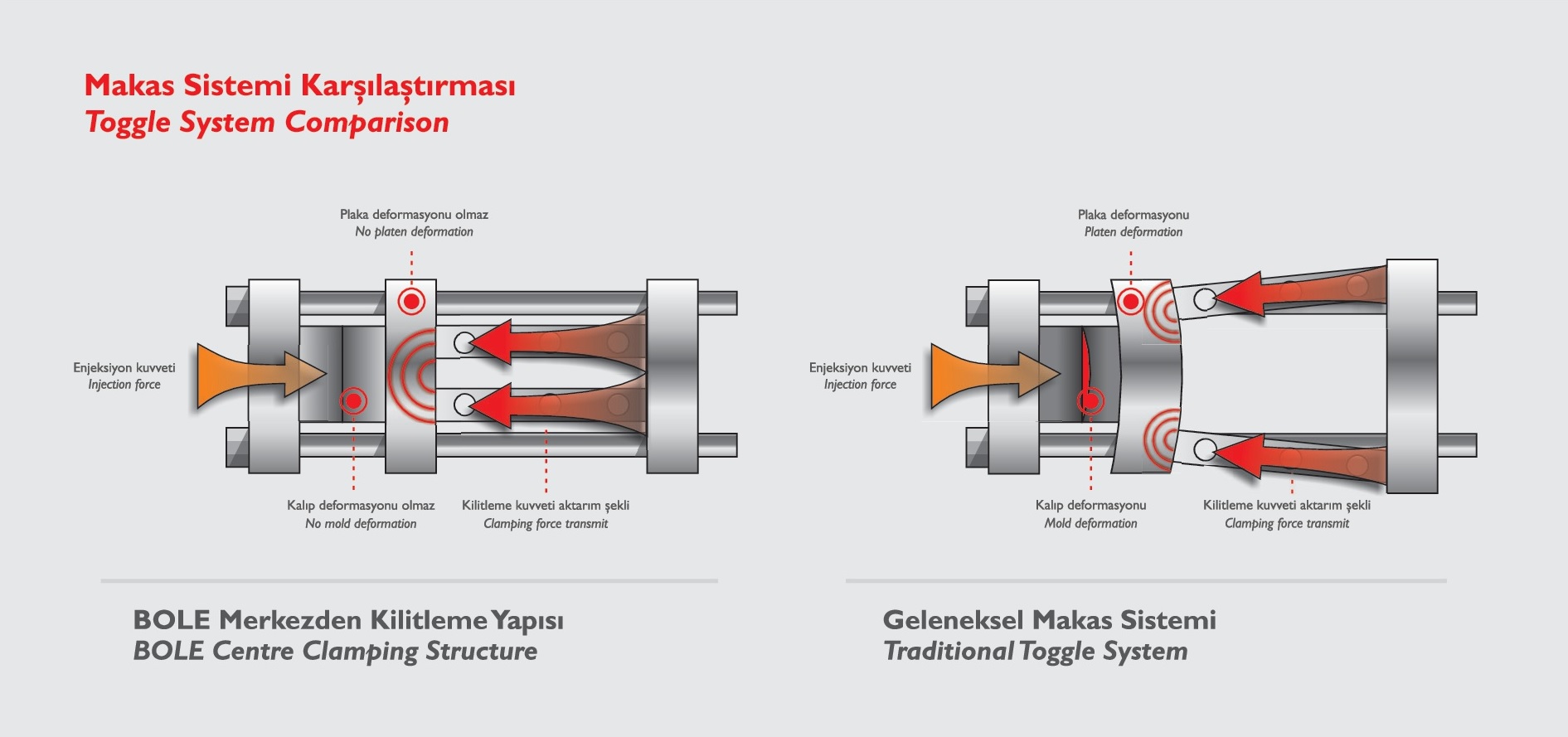

Central Clamping Structure, Invention Patent in China 01.High Utilization of Clamping Force After sample survey, clamping force eciency of BOLE central clamping toggle design can reach 100%. Clamping force eciency of traditional edge clamping force only can reach 80-85%. 02.Material Saving BOLE central clamping toggle design can save 2-5% material for 80% of customers mould (comparing to customer s molds traditional clamping toggle design) 03.High Accuracy Less Possibility of Flash Repetitive positioning accuracy of mold opening&closing: ± 1 mm. Product weight repetitive accuracy: ‑ 0,5%. Less possibility of flash and save flash trim process. 04.Offer Better Protection For Molds and Platens The latest design of clamping structure, averaged force and less distortion for mould platen. Precise low-pressure function for mould closing, proportional pressure control, iso-stress mould platen design, to extend mould life. 05.Bigger Opening Stroke Central clamping structure can provide bigger opening stroke & ejector stroke than other brands stroke and can install larger molds easier (Especially for deep cavity working condition)

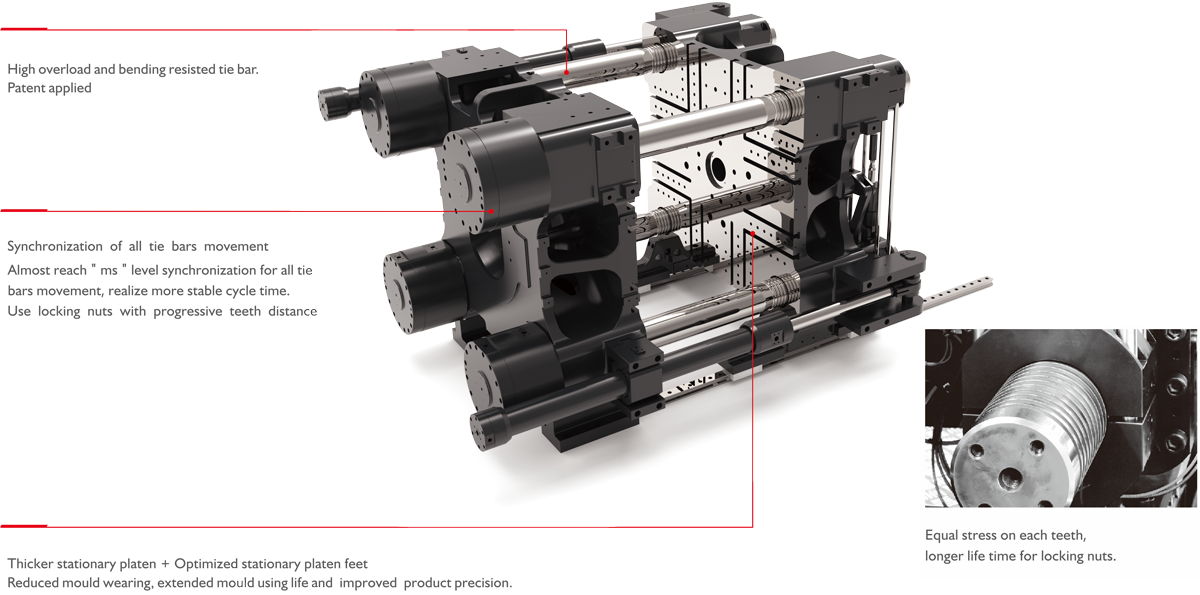

Operate independently to ensure German quality and present European perfonmance perfectly. 01. Break-resisting tie bar Less stress for weak point tie bar, there is almost no risk of fracture. High overload and bending resisted tie bar. 02. High precision & rigidity linear rail DK series two platen machines adopt high precision and high rigidity linear guide coordinates with siliding foot to support movable platen, guaranteening high positioning precision of movable platen and faster opening and closing speed. Without the problem of splashing lıbrication oil, the performance of whole machine gets further impovement. 03. High efficieny German designed plasticising system Orginate from German design Plasticizing System, efficiency excess above 20% of domestic level. Custom made complicated technical requirement, applied to special plasticizing system. All series can fit with A/B/C screw, L/D ratio 23:1, to achive the best plasticizing effect and efficiency. 04. Vertical placed motors & pumps The motor is placed vertically, reducing the footprint. At the same time, the influence of the eccentic load coused by the gravity of the rotor of the motor is reduced, and the motor is more stable. 05. Fast, stable and impact-free locking system Fast, smooth, quiet, more effective lock nut to protect tie bar and nut itself, prolong equipment lifetime. 06. Synchrınized ejection (core) movement Simultaneous eject (core pulling) functions as standard, improve machine cycle efficiency. 07. Special injection cyclinder design The new injection cylinder has extremely low oil return resistance and cooperates with the frame structure of the linear guide to reduce the friction of the injection part and greatly improve the control precision of the injection unit. 08. Equal stress on each teeth Equal stress on each teeth, longer life time for locking nuts. 09. Independent oil filter and cooling system Very compact and less space occupation. Stabilize the entire oil temperature without any other interruption, such as cycle time and other working elements. 10. Stable feding zone temperature The temperature of the lower feed port is incorporated into the closed-loop control of the temperature unit, which improves the efficiency and accuracy of the entire injection unit. Avoiding the influence of unloading agglomeration and misalignment, the injection molding precision is low. 11. Injection pressure sensor The injection pressure is always fed back and the injection curve allows the customer to adjust the product process more conveniently.

Energy-saving By sampling test, the application of the latest servo system technology fort he sama tonnage model to do the same product, under the same condition, Bole machines save 15% at least than the traditional servo energy saving machine; It is recommended to choose the latest electric charging solution onto Bole. Fort he same tonnage model, the energy consumption of charging unit can save more than 35%, and the energy consumption of the whole machine can save more than 15%. Accurate Precision control adopts the latest hydraulic oil circuit design & patent intelligent software control. The repeat precision of opening/losing mold position reach ±0.5 mm; Injection unit adopts linear guide rail & special cylinder with low oil return resistance & patent intelligent software control, and the repeat accuracy of injection weight reach 0.2% according to the inernational standart GB/T25156-2020. Efficienct By sampling test, Bole central clamping structure can save 2-5% raw materials for more than 80% of molds. For example, using the same mold with the same amount of raw materials to do 100 pcs, Bole machşne can produce 102-105 pcs. With German design plasticizing unit, plasticizing efficiency is greater, saving the charging time.

With excellent performance and quality, BOLE MK series multiple IMM will better meet the demand of automobile, household appliances, Daily necessities, food packing and toy industries for their appearance and personalized designand will help custumers improve their core competitiveness. 01.Precise Muld open & close positioning accuracy: ±0.5mm Injection weight accuracy: 3%。 02.Flexible The injection moulding progress is set according to the characteristics of product to ensure product quality 03.Energy Saving Hydraulic servo system has advantages of saving energy, protecting environment and high control accuracy. 04.Economy After sample survey, BOLE central clamping toggle design can save 2-5% material for 80% of customers mold (comparing to Customer s molds clamping toggle design).

Rhong Medium Speed Granulator Integral body design, sturdy and durable, insure a stable performance even after long time using due to granulating material. Low granulating speed and sharp angle design of rotating blades are helpful for smooth and continuous operation. The motor mounted overloading and power source interlock two protection devices, double protection for personnel and motor safe. Special knife blade structure adopting shear principle, made of high contented chromium steel, shred the various plastic in a easy way. The gap of knife is adjustable. they can be dismounted when blunt, to be used repeatedly, long time using life. Separable design, the bunker, main body, mesh frame are dismounted easily, convenient for cleaning. Small size and quipped with casters so as to move easily. High safety grade design to comply with European safety standard. Rhong Heavy Duty Granulator Integral body, sturdy and durable, keep excellent performance after using long time. New designed V-type rotating cutters which can send the feeding material into the center of rotating cutters so to prevent the material from adhering onto the inner side of the cutting chamber. Special cutter design adopting shear principle, made of high-chromium shred, work together with high-speed motor, shred various plastics wastes easily. Electric interlock and motor overload protector provide double protection for the safety of operator and motor. The gap between knives is adjustable, they knives can be dismounted blunt, to be used repeatedly, achieve long time using life. Separable design, the bunker, main body, mesh frame are dismounted easily, convenient for bunker cleaning. With vibration-resistant feet, reduce the noise of vibration. Compact Sound - Proff Granulator Compact design, fully enclosed body, very low noise. New designed V-type rotating cutters which can send the feeding material into the center of rotating cutters so to prevent the material from adhering onto the inner side of the cutting chamber. Special cutter design adopting shear principle, made of high-chromium shred, work together with high-speed motor, shred various plastics wastes easily. Adjustable material inlet in order to feed by conveying belt easily. Shock-proof pad installed in order to absorb vibration while breaking. Equipped with cyclone dust-collector to separate dust efficiently. Special-designed blower conveying system with powerful conveying capacity.. Suitable for breaking various plastic objects including film and bottles. Integral body, sturdy and durable, keep excellent performance after using long time. Single-Shaft Shredder Outside bearing seat design, in order to avoid the dust entering into the bearing, long time using life. Adopt material pusher to increase cutting efficiency. Overloading protector for motor and interlock device, double protection for the safety of personnel and motor. Special designed cutter structure, high-chromium blades, crush various plastics material easily. parcaliyici-bicak Blades and blade-bed are easily to be taken-off and cleaned. Modern design, nice appearance. Equipped with shock-proof feet, reduce the noise of vibration. European design with compact structure, room-saving and easy cleanout. High safety grade design to comply with European safety standard.

Rhong Vertical Color Mixers Vertical mixers that take up little space and can be used anywhere with their wheels. Due to the vertically positioned motor, low noise ratio and longer operating times have been achieved. Design with low energy consumption and high capacity. The top cover and body parts of the mixer are manufactured for high speed operation. The mixing timer can be adjusted between 0-30 min. Due to the unique structure of the mixer, the time of mixing is shortened and electricity saving is provided. The mixing blade is produced stainles steel and can be easily cleaned. Rhong Spiral Color Mixers Materials in the tank can be round stirred like swirl to decrease mixing time. The surface of machine made of stainless steel where will be contact the equipment and raw material in order to clean easily, and avoid rustiness. Low power, large mixing capacity, sealed mixing ,mixed evenly in short time, no leakage. Overload protection device for motor and chain protection device for power source to double protect the safety of motor and workers. Equipped with oil refueling device and dust-proof plate under the frame in order to durable bearing. (Apply to RSM-500/100). Auto-stop device, the setting range for auto-stop is up to you, easy and durable. Equip with hand-operated cut-off plate for discharge port, convenient for discharging.

The VLM single-phase feeders are designed to automatically convey plastic granules to processing machines, drying hoppers and dosing units. Single-phase feeders are equipped with a built-in extraction unit. Material extraction capacity of up to 600 Kg/h and maximum distance of 15 m. The microprocessor board controller and the programming keyboard allow the operator to program and control the machine easily. TECHNICAL SPECIFICATIONS: Microprocessor board controller for 8 vacuum line pumps and 56 receivers. Portable keyboard with digital display. Integrated management of: 900W double stage blower (the VLM 25 model mounts a 1800W brushless blower) Automatic filter cleaning with compressed air Inspection hatch with stainless steel venting filter Control through a keyboard and a LED digital display signalling the operating status and any alarms Built-in double lid dividing the motor area from the blower, for improved operation. Aluminium fastening ring, for 360° installation Extraction pipe and probe included. ACCESSORIES: Skill and professionalism PVN proportional valve, with percentage settings. Acoustic alarm. Pirex mini-hoppers for direct installations on machines. THE ADDED VALUE: Skill and professionalism EASY TO USE LOW MAINTENANCE SAFE AND RELIABLE QUICK INSTALLATION VLV model compressed air feeder for small production batches of up to 20-30 kg/h. Entirely made of anodized aluminium with a Pyrex stub pipe with adjustable level sensor, the VLV feeder is equipped with a high-efficiency suction probe for a Venturi-based pneumatic conveyance. It can be installed directly on a machine or on a small maintenance hopper. The AMM series automatic manifolds are the ideal solution for the distribution of plastic materials inside the plant. There are 4 models available, with pipe diameters of 40 - 50 - 60 - 70mm. TECHNICAL SPECIFICATIONS PLC Siemens controller and touch screen interface The controller can manage up to 4 modules. Gearmotor with built-in self-braking system. Internal structure made of wear-resistant stainless steel. THE ADDED VALUE Reliable The precision of the mechanical components, and the PLC control unit with its position sensors ensure absolute reliability. Does not require floor space and can be expanded Its design, modular and with the possibility of expanding its functions at a later time makes of this product an innovative solution in the plastic industry. Safety No risks for the operator. The moving parts are all inside the machine. The VLP powder feeders are a smart solution for the pneumatic conveyance of plastic materials in powder form. They can also be used to convey food, pharmaceutical and chemical product under top hygienic standards. Ideal for free-flowing powders with particle sizes from 10 to 200 μm and bulk density from 0.35 to 1.8 kg/dm3. They can be used also with smaller sized particles, using special sintered filters. Available also in the version for Matrix centralised systems and external PD vacuum pump. The TMM series stainless steel receivers are suitable for use in MATRIX 4.0 centralised systems. There are 8 models available, ranging from 2 dm3 to 100 dm3. TECHNICAL SPECIFICATIONS: Stainless steel construction. Hinged cover. High negative pressure operation. Automatic filter cleaning Flap-type drain valve and wear-resistant gasket. Air vent with hatch and integrated metal filter. ETHERNET connection ACCESSORIES: Pneumatic drain Proportional valve MWS weighing system-ready THE ADDED VALUE: Easy to use Easy to clean and maintain Safe and reliable Quick installation with a 360° orientation Lighted status indicator The PM series extraction units with power from 3 to 30 kW are used for the pneumatic conveyance of production batches of up to 4500 kg/h over distances of up to 200m. They are used in Matrix centralised loading systems. TECHNICAL SPECIFICATIONS: 1-3 stage side-channel blowers Cam pumps Lobe pumps Self-cleaning filters with polyester cartridges and

The company has no registered brand information.

TR

TR