| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

GNEUSS KUNSTSTOFFTECHNIK GMBH

Mönichhusen 42 / North Rhine Westfalia / Bad Oeynhausen / GERMANY

|

Contact Info: +49 5731 53070

|

Hall: 11A

Stand: 11A-140A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

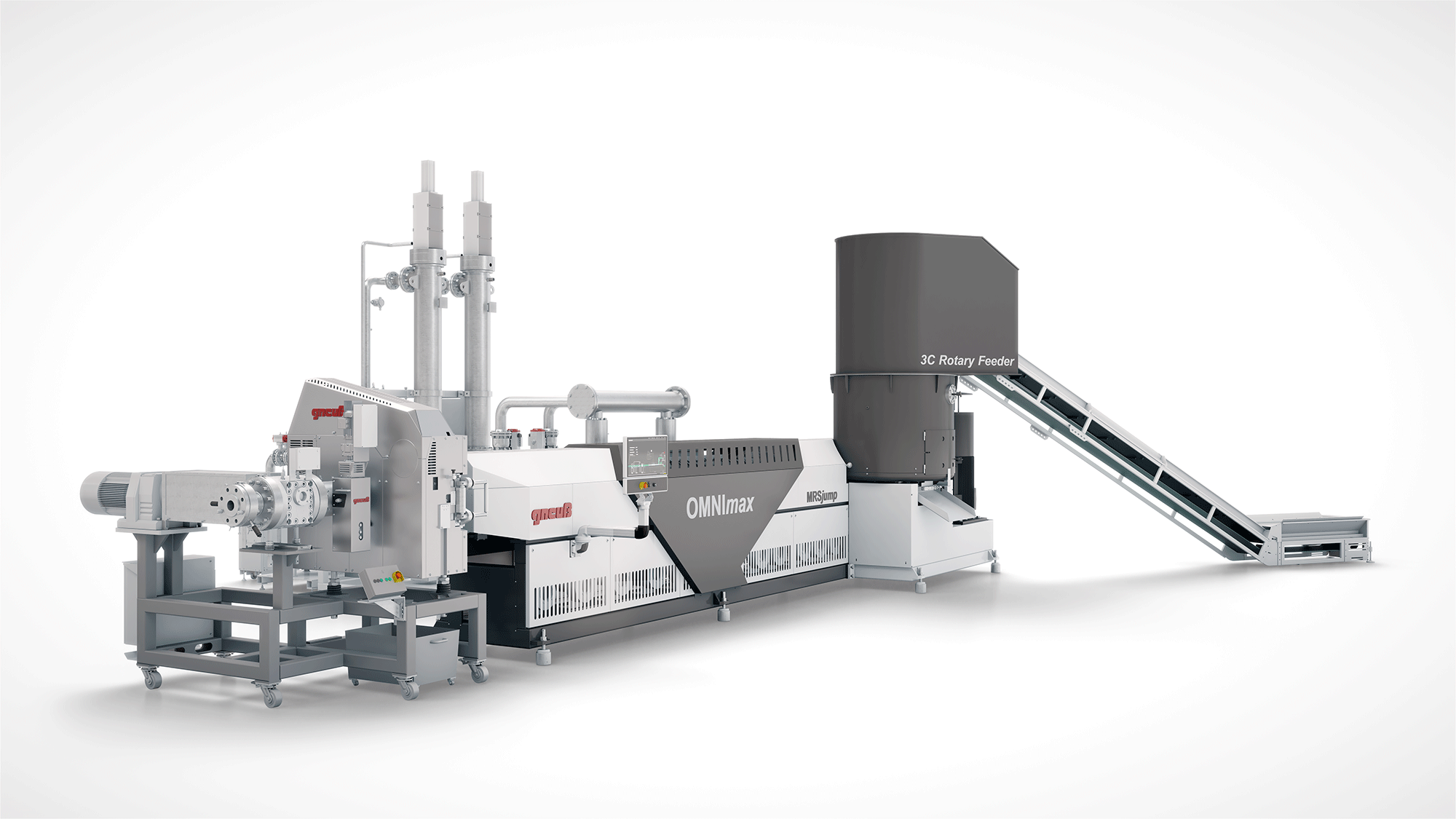

With over 40 years of experience and over 100 patents, Gneuss is a supplier of innovative solutions for the recycling industry. Based in Bad Oeynhausen, Germany, Gneuss is committed to upholding the expectations of its customers with its equipment made in Germany but delivered and supported worldwide. The Gneuß MRS extruder (patented) is a key element of the Gneuß OMNI Recycling Systems and offers new possibilities for recycling, with its highly efficient devolatilisation for extrusion of hygroscopic polymer such as polyester and for the extraction of volatile contaminants. Additionally, and as part of the Gneuß OMNI Recycling Systems, Gneuss offers its unique and also patented process constant and fully automatic screen changers and high-quality melt pressure and temperature sensors, making the efficient processing of highly contaminated materials possible.

An OMNImax recycling system consists of a combination of different Gneuss products and technologies optimized for a specific end application. The system typically consists of a 3C rotary feeder, an MRS extruder, a vacuum system, a fully automatic RSFgenius melt filtration system and a VIS online viscometer.

The MRS extruder is based on the conventional single screw extruder, but is equipped with a multiple screw section, for optimum devolatilisation. The MRS extruder has a robust design and a wide range of applications. It is particularly suitable for recycling applications, such as bottle, fibre or sheet recycling. Various international approvals confirm the high cleaning efficiency.

With regard to achievable product quality, economic efficiency and in terms of operator and maintenance friendliness, the RSFgenius offers unrivalled possibilities. This fully-automatic and pressure-constant filtration system can be used in virtually any application, for automation of the production process and for the manufacture of a high quality final product. The RSFgenius is particularly well suited for ultra-fine filtration, the filtration of thermally-sensitive melts and the filtration of materials with a high contamination level.

The company has no registered brand information.

TR

TR