| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

GUANGDONG BAST EXTRUTECH CO., LTD

NO. 1 ZHANXIANG ROAD, FENGXIANG INDUSTRY PARK, DALIANG, SHUNDE / GUANGDONG PROVINCE / FOSHAN / CHINA

|

Contact Info: +86 138 2559 8416

|

Hall: 10

Stand: 1015E

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

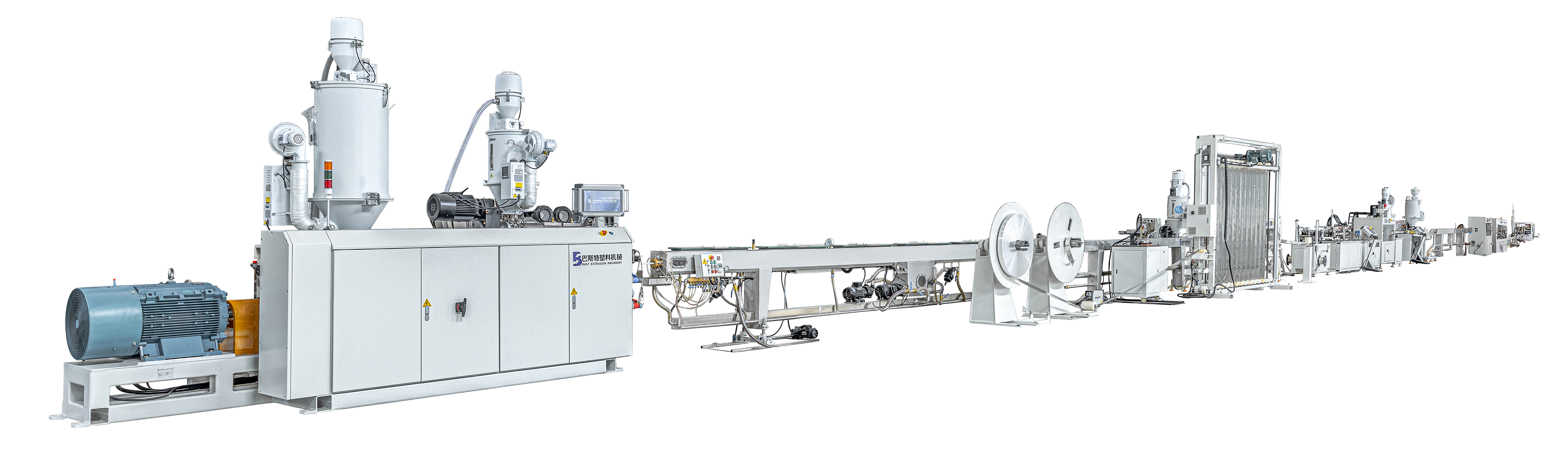

GUANFDONG BAST EXTRUTECH Co., LTD. was established in 2008, and committed to the R&D and innovation of high-end plastic machinery and equipment. The company is oriented to customers in all regions of the world, and its business scope covers three segments Pipe Extrusion Equipment, Laminating & Casting Equipment, Heavy Bags / Cold Stretching / Heat Shrinking Film Blowing Equipment. It is an equipment supplier integrating technology R&D, production and assembly, sales and service.

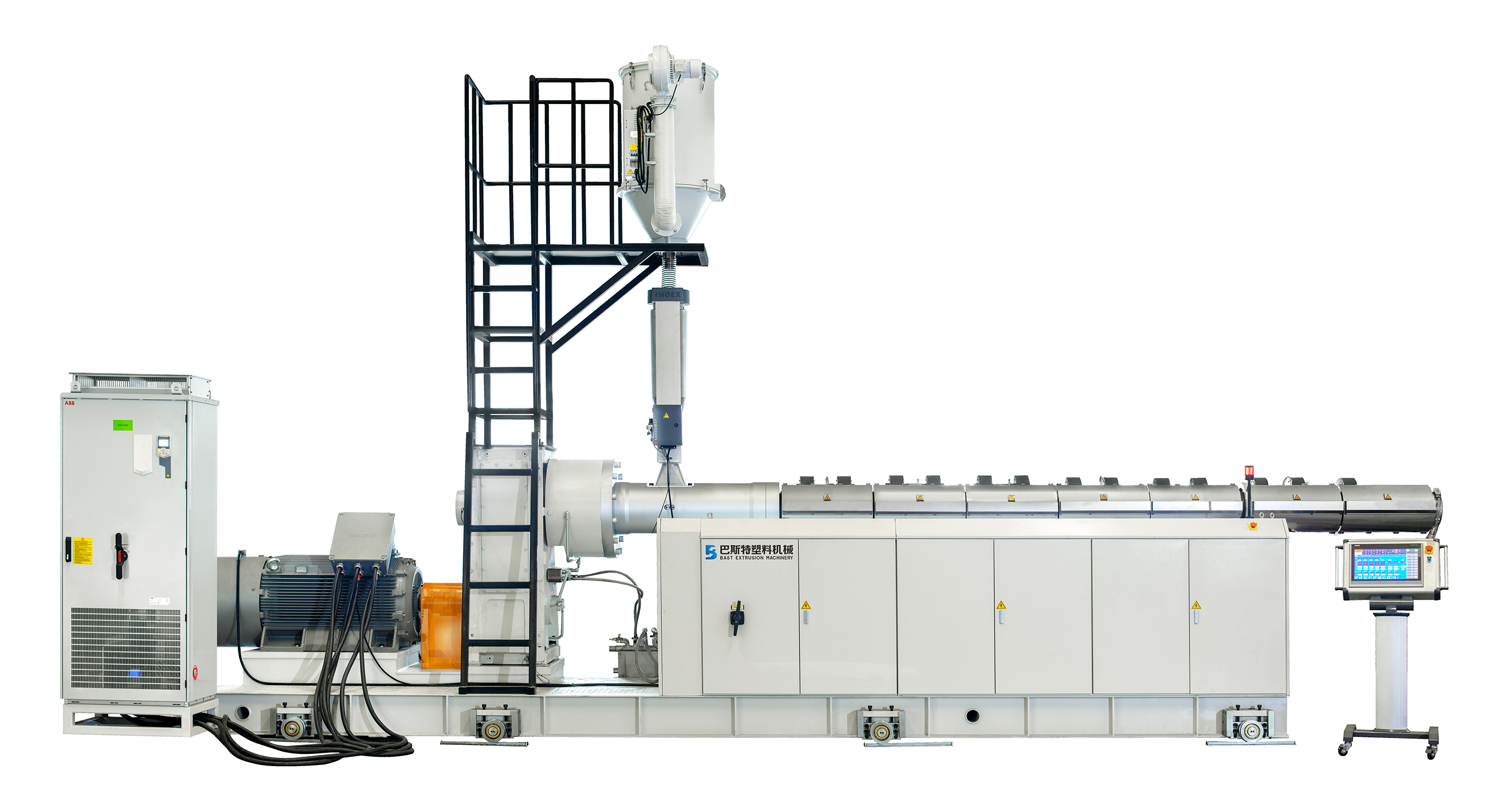

1、Combination of spiral feeding barrel and separate screw design, it guarantees a high plasticizing rate and excellent melt uniformity. 2、Using water-cooled air conditioner, it ensures electric components work in a constant temperature and humidity, which makes them more stable and get longer lifetime. 3、Austria B&R or Germany SIEMENS PLC operating system with touch screen for option, data storage and other advanced function features, for better observation, operation, maintenance, and remote monitoring. 4、Equipped with high quality gearbox, its stability, noise and temperature levels fully meet the imported gearbox performance even at high throughput rates. 5、The communication signal is digital signal, which has strong antiinterference ability and ensure accurate control and feedback. 6、The temperature control range is ±1 degree. 7、Ethernet connection is adopted for all communications to meet the data acquisition requirements of Industry 4.0, visual production and remote monitoring can be expanded in the future.

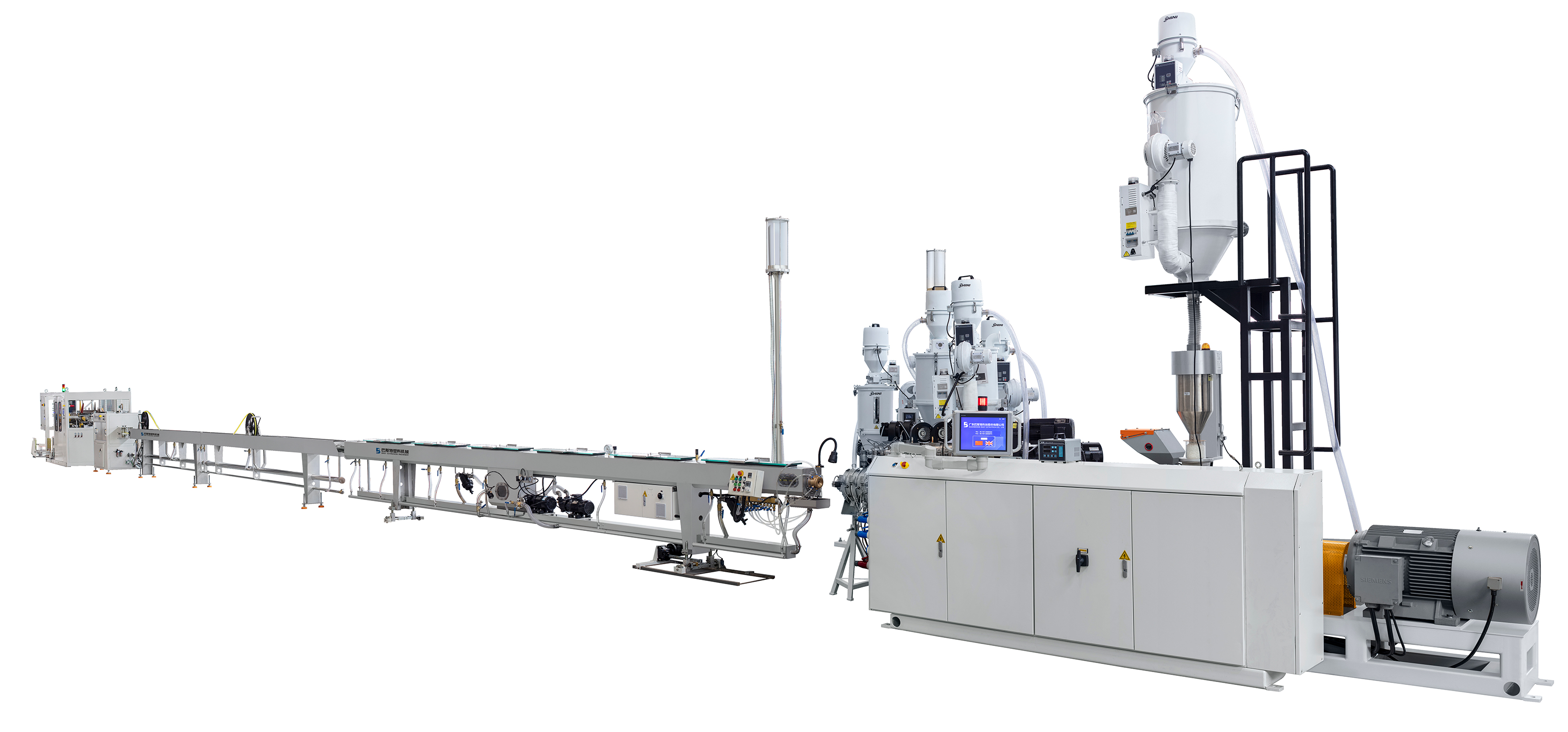

Pipe specification: HDPE 16-2000mm 1、The motor speed of extruder and haul-off are measured and feedback by the encoder, which ensures the stability of screw speed and traction speed. 2、With optimized screw design for extruder, it can guarantee a good plasticizing effect under the high screw speed, and achieve high output and low power consumption. 3、The inner cooling system of die head improves the cooling effect, shortens the cooling length, reduces production costs, and increases output. 4、The extrusion line can achieve various control of downstream equipment by the extruder. 5、The extrusion line uses multiple internationally reowned brand components.

1、Suitable for the high speed pipes less than 32mm. The line speed can achieve 100m/min. 2、Pipe Standard: PERT 16 2.0mm 3、Line Speed: 60m/min 4、Output: 320kg/h

1、High integration control, communication integrated gravimetric, energy consumption sheet, color master machine etc. 2、PPR extrusion line with color master batch feeder system, automatically matching of Color Master batch proportion according to the transporting of main material, to ensure quality of product and save more raw material. 3、The vacuum calibrator adopted integrated design of the tank, and tempered glass cover is easy for observation. Heat circulation system is used inside of the tank to reduce energy consumption and also the cold-brittle of the material. 4、The combination of Haul-off and cutter with 4 single working station, reduce land occupancy and control synchronously with extruder. 5、lt can realize production and packing at the same time, to make the production efficiency maximize.

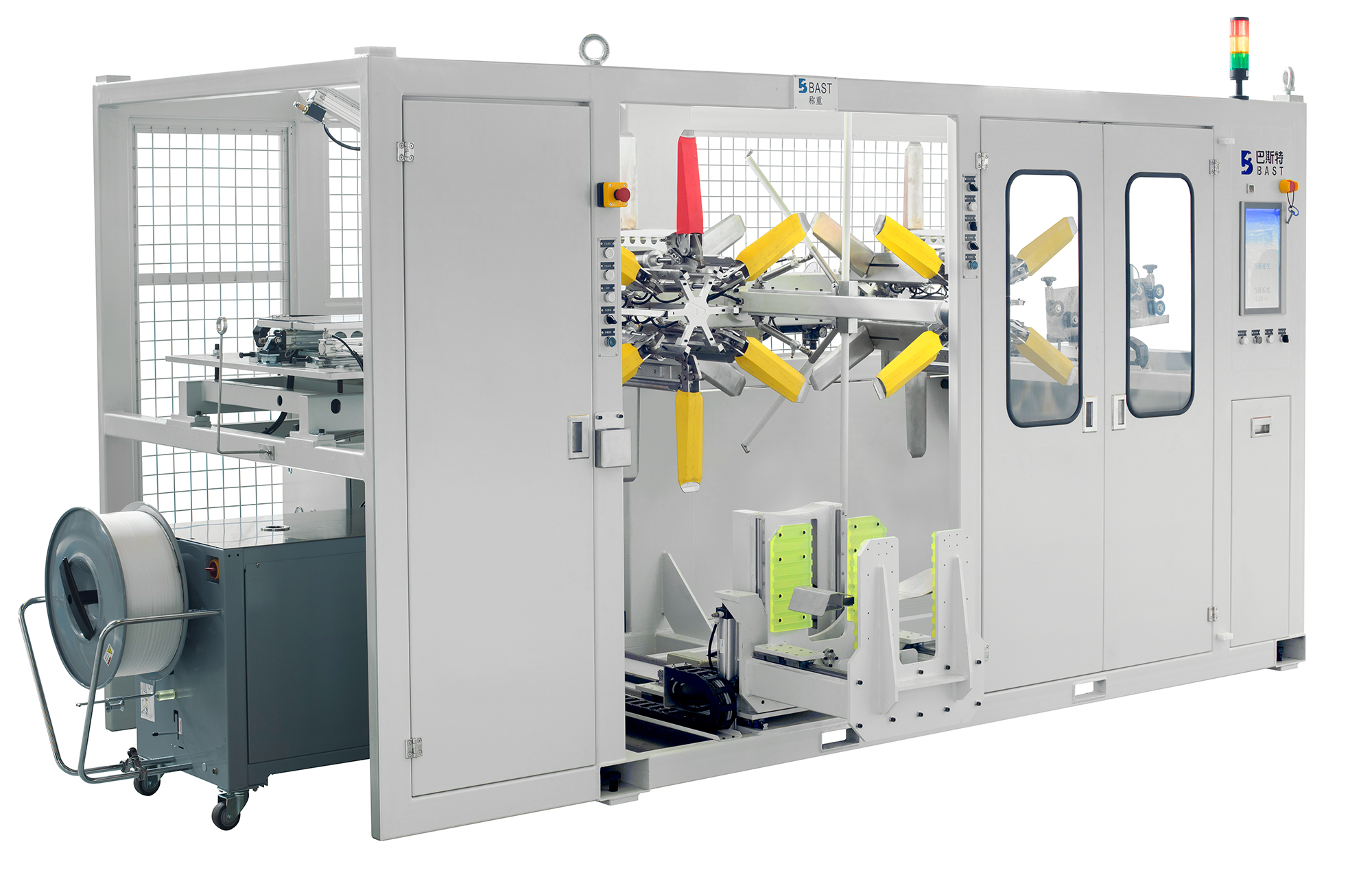

1、For automatic coiling and strapping of 8~32mm PA、 PE、 PERT pipe. 2、With the function of automatic emissions wiring, cutting, roll-changing, strapping, unloading, online weighing. 3、Through digital programming control, the emissions wiring, coiling and roll-changing are driven by separate servo motor. 4、Roll-changing, cutting and clamping are completed automatically, avoiding time wasted for caching, rewinding and possible misoperation. 5、The integrated design of feeding guide and reel greatly reduces the failure rate.

1、Product: Stretch Hood 2、Output: Feed Section Grooved Up To 650 Kg / h 3、Line speed: 80-150 m / min 4、Film thickness deviation: (2sigma) ±4%

1、Product: Heavy Duty Packaging Bag Film 2、Output: Feed Section Grooved Up To 350 Kg / h 3、Line speed: 100 m / min 4、Film thickness deviation: (2sigma) ±4%

1、Model: 1550 - 2700mm; The whole machine adopts integrated PLC for control+ distant diagnose module. 2、The extrusion system adopts high effective single screw/double-screw + metering pump, with stable extrusion and good plasticization. 3、Optional for manual/auto die+ manual/auto thickness gauge; Online trim reclaiming 4、Pre-heating crystallization unit; Automatic dual-station rewinder

1、Ekstruder Vida Yapılandırması:Ф100/Ф180/Ф110, Ф150/Ф150/Ф150/Ф150 2、Film Yapısı: ABCBD, 5 katmanlı ko-ekstrüzyon 3、Kalıp Genişliği: 350-5500mm; Cpp Film: 20-100 μm 4、Üretim Hızı: 80-220m/dak; Geri Sarma Dış Çapı: 1000mm, 1200mm 5、Üretim Çıktısı: 1600Kg/saat

1、High integration control, communication integrated gravimetric, energy consumption sheet etc. 2、Highly automated, SIEMENS PLC control system with high precision, equipped with fully automatic coiler with stripping and unloading device to reduce labor costs. 3、The aluminum pipe adopts imported butt welding argon arc/laser welding, with tight & smooth welds, stable & reliable welding quality and strong productivity. 4、High layering accuracy, professional coating die extrude glue thinner and more uniform, reducing consumption of raw material. 5、Ethernet connection is adopted for all communications to meet the data acquisition requirements of Industry 4.0, visual production and remote monitoring can be expanded in the future.

No represented companies found.

The company has no registered brand information.

TR

TR