| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

HASTEK PLAS. TEKN. OTOMASYON SİST. PAZ. SAN. TİC. LTD. ŞTİ.

Akçaburgaz Mah. 3108 Sk. No: 6 PK: 34522 Kıraç, Esenyurt / İSTANBUL / Esenyurt / İSTANBUL / TÜRKİYE

|

Contact Info: +90 534 741 5842

|

Hall: 8

Stand: 801 - 806

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

HASTEK Ltd. Sti. It was established in Istanbul in 1998 with its sectoral experience and knowledge on plastics for more than 60 years. HASTEK provides service with its general directorate, showroom and warehouse area in Istanbul Kıraç on an area of 3500 square meters, and Aegean regional directorate in Izmir Gaziemir. With its expert staff, HASTEK closely follows the developments in world plastic technology and provides machinery, automation systems, auxiliary equipment and most importantly, instant technical service to the Turkish plastics industry. HASTEK has been maintaining its steady development since the day it was founded and represents companies of Asian and European origin that have proven their expertise in their field and become brands.

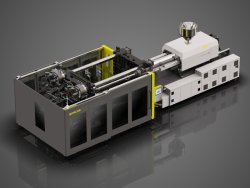

Borche BU6800 is the biggest two platen injection molding machine in Asia in terms of combination of clamping force and injection volume as well as power saving effect. The clamping force reaches to 68000 KN. Borche Intelligent Two-Platen IMM are with superlong lasting tiebar, precise, stable and reliable performance, less footprint and less mainetenance headaches. Borche BU two platen injection molding machine can be widely applied to aerospace field, automotive industry, transportation field, household appliance, and new rural construction.

The Bi-M Series offers high power, precise control, stability, and a high level of versatility to meet various production requirements.

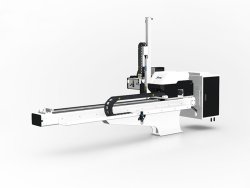

With its robust and durable structure, the ST3 series take-out robots offer excellent performance and speed. Thanks to the servo motors used, they are ideal for applications requiring positioning at various points. They can be used with plastic injection molding machines ranging from 100 to 3600 tons. Available with standard or telescopic arm options, the ST3 series supports stacking, quality control, and insert (in-mold product placement) applications.

The INDUSTRIAL FRIGO brand GR1AC series Industrial Chiller is designed for use in all industries requiring chilled water between 8°C and 25°C (down to -5°C if needed). The GR1AC series, offered with a high standard of equipment, can be customized at many points based on the needs of the process (high-pressure pump, high-pressure fans, redundant pumps, integrated remote control capabilities). Thanks to its tropical-type condensers, the GR1AC series can operate at ambient temperatures up to 45°C. These industrial chillers, equipped with scroll compressors, soft-start automatic speed-controlled fans, and large condenser surfaces, provide low energy consumption. They are ready for operation with built-in tanks and pump groups. The user-friendly design, which allows easy access to all internal components, facilitates maintenance and repair, offering significant convenience to operators and maintenance teams. With a hot-dip galvanized body and an IP 55 protection rating, it is durable in harsh outdoor conditions.

The dry cooler BRW/A have been designed for refrigeration systems in pressurized closed circuit able to dissipate the heat generated by production processes without requiring water consumption and with minimum energy consumption. Units are composed by an heat exchange coil, a hydraulic circuit complete with pump, axial fans and control panel.

Products manufactured with injection molding machines may be defective due to improper mold temperature settings. This is especially critical in the production of engineering plastics (PET, PC, PA group, ABS) that require high strength and aesthetic quality, where mold temperature precision and control are of great importance. Production using molds that are not at the correct temperature can result in surface and shape defects, lower strength values in products, incomplete products, and dimensional variations. Additionally, improper mold temperatures can cause unnecessary increases in injection pressure. Water-type mold conditioners eliminate these and similar problems, ensuring dimensional accuracy of the products.

The MC-WEIGHT device is specifically designed for extruder applications. Based on the loss-in-weight measurement principle, the MC-WEIGHT precisely monitors the amount of raw material consumed in kg/hour. In addition to being used for gram/meter line control, it also provides the actual extruder capacity value for additive dosing units.

SSM-U is mainly used for mixing plastics such as raw materials, masterbatch and recycled materials. SSM-U can not be used dealing with plastic powder and all kinds of foods, chemicals, and inflammable, explosive and volatile materials. Bulk density should be taken into account when the dimension of material is uneven or in other forms. Collocated with suction pipe for convenient material transport

The SCR Series Closed-Loop PET Crystallizers are used to crystallize PET materials, such as bottle flakes, that are intended for recycling before further processing. Depending on the application, the crystallized material can undergo a secondary moisture removal drying process for direct processing. The system typically consists of an insulated silo, heating elements, and a mixer unit. The mixer unit ensures the movement of the low-flow raw material inside the silo, allowing the heat effect required for the crystallization process to be evenly applied to all the material. Raw Material Drying Systems are used to remove moisture and dry plastic raw materials before the injection process.

The GXC Series Shredders are specifically designed to provide efficient shredding performance at very high capacities. With various models available in rotor widths ranging from 800 to 2000 mm and motor powers from 55 to 315 kW, they offer the necessary power and capacity for demanding applications. Thanks to different rotor configurations, they are highly versatile in handling even the toughest products in plastic production facilities. Whether for hollow and voluminous items, or flexible materials like rubber, film, and non-woven fabrics, as well as profiles, pipes, and thick sheets, the GXC Series ensures excellent efficiency in your facility.

- BORCH MACHINERY CO., LTD.

- GENOX RECYCLING TECH CO., LTD

- SHINI PLASTICS TECHNOLOGIES, INC.

- INDUSTRIAL FRIGO S.R.L.

- MOVACOLOR B.V.

- MAGUIRE IMEA FZCO

- MESUTRONIC

- GAUSS MAGNETI

- ACERETECH

TR

TR