| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

HCI CONVERTING EQUIPMENT CO., LTD.

26, 7th Road, Taichung Industrial Park / / Taichung / TAIWAN

|

Contact Info: +886 4 2359 0632

Web: https://www.hci.cc/

|

Hall: 10

Stand: 1009D

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

HCI, a leading company in Taiwan supplying converting equipment to the label, medical and flexible packaging industry, such as Shrink Sleeve Seaming Machine, Rewinding/Inspection Machine, Cutting Machine, Slitting Machine, Pouch Making Machine, Bag Making Machine, etc. has built its reputation on innovation, quality and customer service. Established in 1982, HCI is committed to providing the best solution to clients converting needs with its most comprehensive technology services. For over 40 years, HCI Converting Equipment Co., Ltd. has installed more than 4,000 machines worldwide and assisted its clients increased their efficiency with their technology and experienced teams.

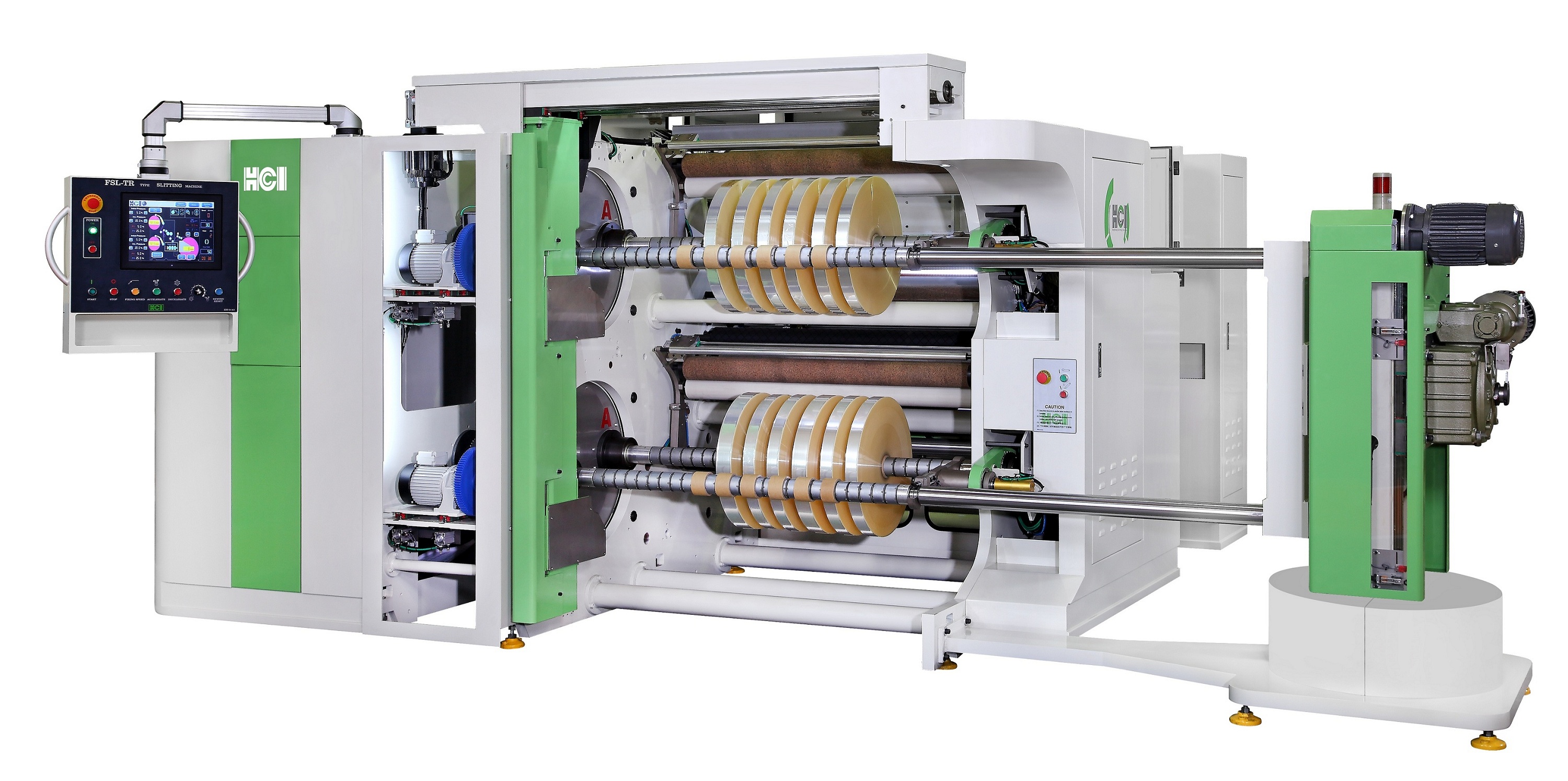

HCI s newly launched FSL-TR1300 turret rewind slitting machine is designed for automatic slitting and rewinding operations, with automatic splicing and roll changing, stand-by paper core auto positioning, finished roll pusher and unloading device to increase productivity and reduce the operation down time. The HMI operating system equipped with a color touch screen provides easy-to-learn operations and memory of operating parameters, which makes the product quality stable.

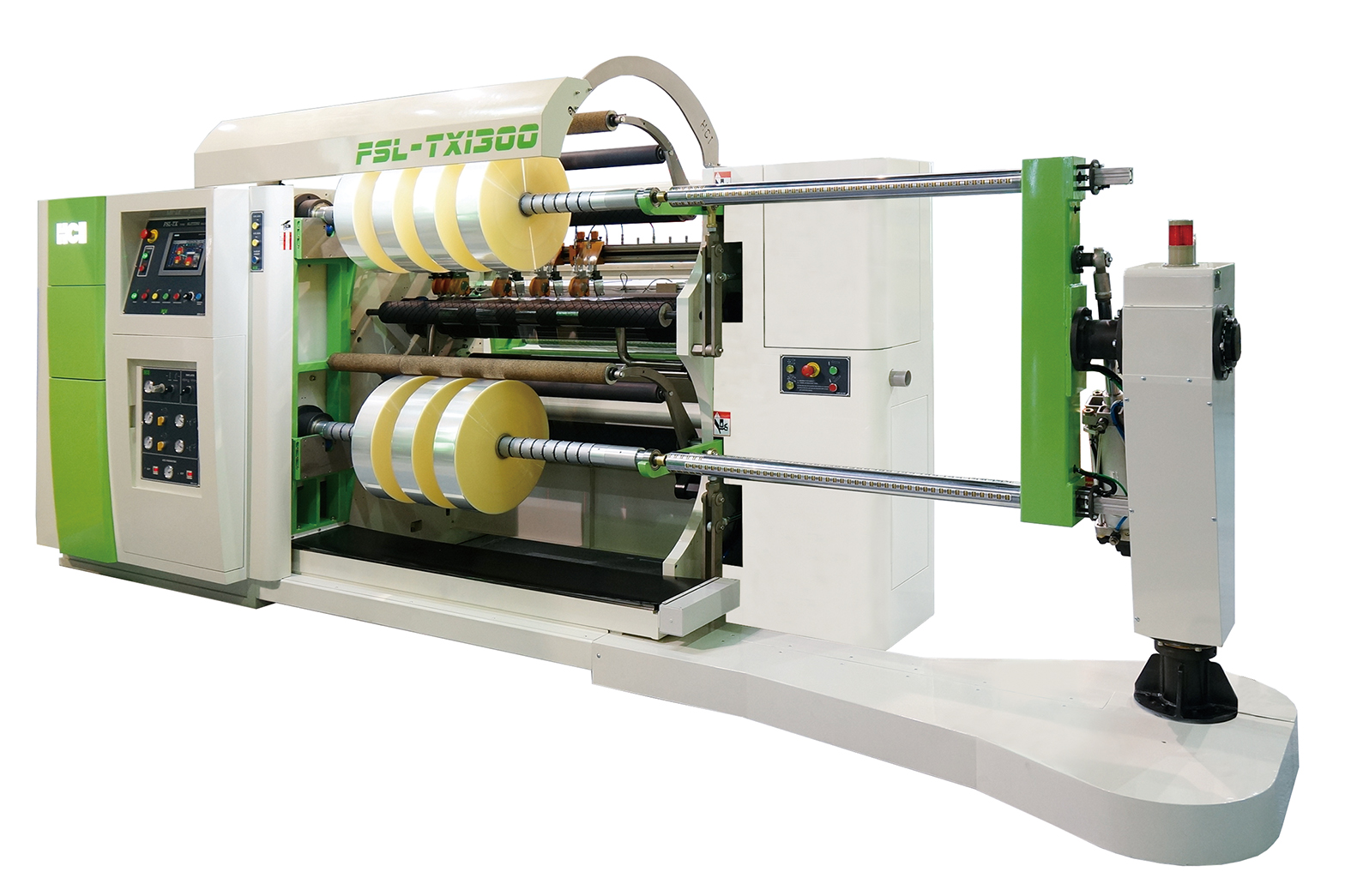

800 Rewind Slitter Rewinder has been purposely designed for large rewinding OD requirement, for slitting product OD as large as 800mm and line speed up to 400m/min. Solid shaft-less unwind stand design for roll weights over 1 ton; shortest web path design, all cutter set ups can be completed at the front of the machine. With all new rewinding shaft technology, it is suitable for slitting and rewinding of all kind of film roll of uneven thickness.

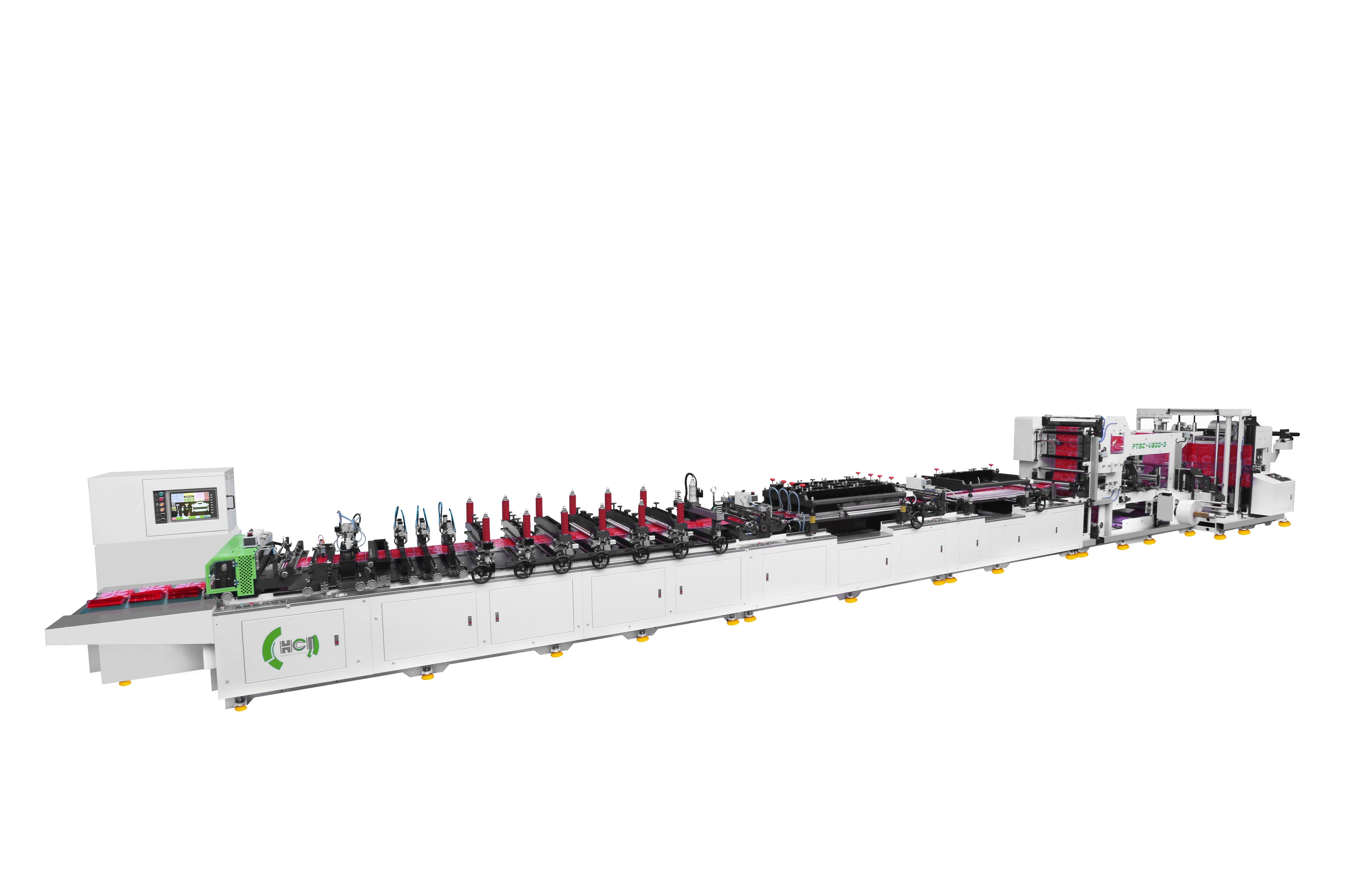

Main drive and material feeding by servo motor which providing the constant sealing time even cutting speed varied.

Suitable for sealable co-extrusion films, multi-layer films such as laminates of Polyester, BOPP, and CPP This machine is ideal for the production of 3-side sealing bags, stand-up pouches, bottom gusseted stand-up pouches, zipper bags, combined stand-up/zipper pouches, four side seal bag

Unwind / Rewind Tension Auto Control, equipped with loadcell and dancer roller device, which can eliminate all kinds of tension fluctuation and instantaneous changes caused from auto splicing.

This cutting machine is suited for perforating and cutting operations for various shrink labels or electronic material and optical film.

It is specially designed for the production of medical sterilization pouches and reels. The sterilization reels making machine can be produceed in multiple lines and with four-shafts winding station, which greatly improves the production efficiency.

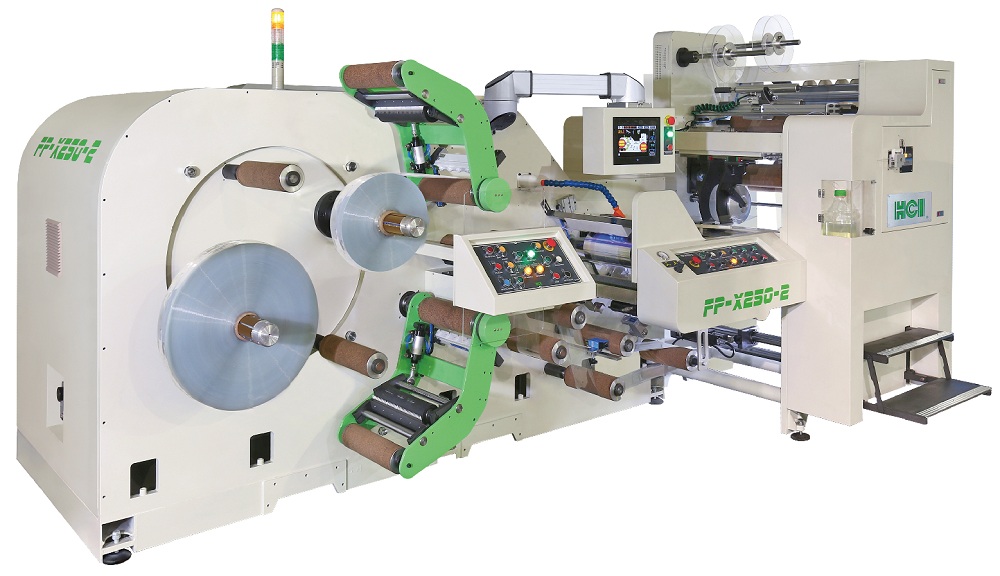

Both unwind and rewind equipped with servo-motor for precise tension control. The winding direction can be changed any time with forward / reverse jogging functions.

Single winding direction, entry level rewinding/inspection machine.

Cantilevered unwind air shaft for quick change over, the roll diameter can reach to 700 mm with 2 different web path for inspection of printing defects or seaming quality.

- HCI

TR

TR