| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

HİDROPAR HAREKET KONTROL TEKNOLOJİLERİ MERKEZİ SAN. TİC. A.Ş.

İnönü Mahallesi Cumhuriyet Caddesi No: 31 Gebze Plastikçiler Organize Sanayi Bölgesi / Gebze / KOCAELİ / TÜRKİYE

|

Contact Info: +90 262 643 8411

|

Hall: TÜP GEÇİT

Stand: F14 - F17

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

In 1998, we set out with the goal of integrating engineering with art, industry with nature, factory with the environment and technology with life. Our aim has been to understand the nature of movement, to develop and direct it, and in the process to take control of it by being inspired by it. Since our foundation, we have been collaborating on major projects with our solid engineering infrastructure and specialized partner companies. By deeply specializing in different motion and control technologies, we are taking firm steps towards providing multidisciplinary engineering solutions. With this vision, we aim to become the center of industrial motion control technologies in the world. As HKTM, we realize automation solutions and projects in the fields of robotics and hydraulics. We also distribute many global industrial equipment brands such as Bosch Rexroth and offer high quality products and services to our customers. We are taking a leading role in the production of injection molding machine robots by integrating the extensive knowledge we have gained over the years into the plastics industry. We continuously focus on innovation and quality to meet the needs in this field and continue to add value to the industry. With this approach, we continue to offer our customers the most advanced and reliable solutions.

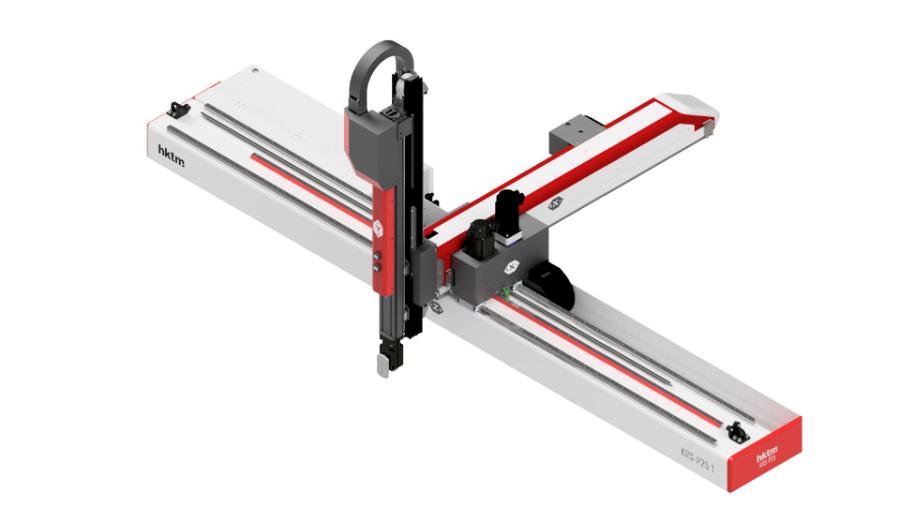

KRS series robots are designed for injection molding machines by combining HKTM s know-how and 25 years of industry experience with advanced technology. Thanks to their proven software, these robots work in synchronization with every movement of your injection machine, keeping the robot s cycle time to a minimum. Thanks to their dynamic servo motors, high-precision linear motion components and engineered design, KRS series robots can operate at the same speed and positions in every cycle for part picking, insert placement, IML (in-mold labeling) and quality control applications. Thanks to its internationally recognized software base, it integrates seamlessly and easily with all injection molding machines and applications. Servomotors with absolute encoders are used in all axes, which allows the robot to remember its position after power failures, avoiding time losses. Axes using helical rack and pinion keep the noise level during movement at an optimum. The rail carriage assemblies used maximize precision movement and rail carriage wear times. The torque control (X Free) feature on all three axes prevents damage to the robot axes during the product picking process.

With our automation systems, we meet all your needs from a single point and in the most accurate way. Our team of experienced and specialized engineers works to provide you with the best, most suitable and fastest solutions. With systems designed specifically for your needs, high quality components and innovative technologies, we offer solutions that will optimize your operations by increasing your productivity. We are happy to provide you with professional support every step of the way, prioritizing customer satisfaction.

No represented companies found.

The company has no registered brand information.

TR

TR