| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

İNAN GERİ DÖNÜŞÜM SİSTEMLERİ A.Ş.

KAVAKLI İSTİKLAL MAH. 5006. SOK. NO: 9 PK: 34596 / SİLİVRİ / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 280 0376

|

Hall: 11

Stand: 1110

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

İNAN MAKİNE continues to bring innovation to the Recycling Industry with its half-century experience. SINCE 1962 15.000 m2 CLOSED AREA 90 MASTER STAF EXPORT TO 67 COUNTRIES IN 5 CONTINENTS We bring innovation to the plastic recycling industry INAN MAKINE started its first production in a small workshop in Levent Industry area in 1962, it has been producing plastic size reduction machines and recycling washing, drying, extrusion systems needed by national and global plastic manufacturers and recycling companies in its factory which has 15.000 m2 closed area. Inan Makine has strengthened its position with its service quality, customer satisfaction, finding modern and technological solutions to meet the changing needs and expectations of its customers, timely intervention to problems, training and technical services we provide after sales, as well as the guarantee and trust we have provided. With the pride of leaving behind half a century in the production of these recycling machines, İnan Makine has become an assertive name in the sector and positioned among the best quality manufacturers and continues to offer the solutions needed by the plastics industry without sacrificing quality and principles with its expert staff, manufacturing power, machinery and production technologies. MACHINES AND SYSTEMS MICRONIZING MACHINES, CRUSHING MACHINES, SHREDDERS, WASHING SYSTEMS, DRYING SYSTEMS, GRANULE EXTRUSION SYSTEMS, TRANSPORT AND STORAGE SYSTEMS. RECYCLING SYSTEMS PET/PET-E BOTTLE AND SHEET WASHING LINE HDPE/PP WASHING AND GRANULE LINE (BOTTLE, CAP, DRUM, BARREL, etc ) (3D - RIGID PLASTICS) LDPE/LLDPE/PP WASHING AND GRANULE LINE (NYLON/STRECH FILM, BIGBAG/SACK, etc ) (2D - SOFT PLASTICS) OUR ACTIVITY AREAS Large Volume Wastes Industrial Wastes Plastic Barrels Plastic Cases Plastic Pallets Plastic Extruder Scraps Plastic Film Materials Cable And Computer Scraps Textile Products Paper and Cardboard Wood Aluminium, Copper All kinds of plastic pipe, profile, sheet, copper, scrap, rope, sack, nylon, carboy, pet and hdpe bottle, etc size reduction and recycling of plastics washing, drying, extrusion systems we provide with the technology we produce.

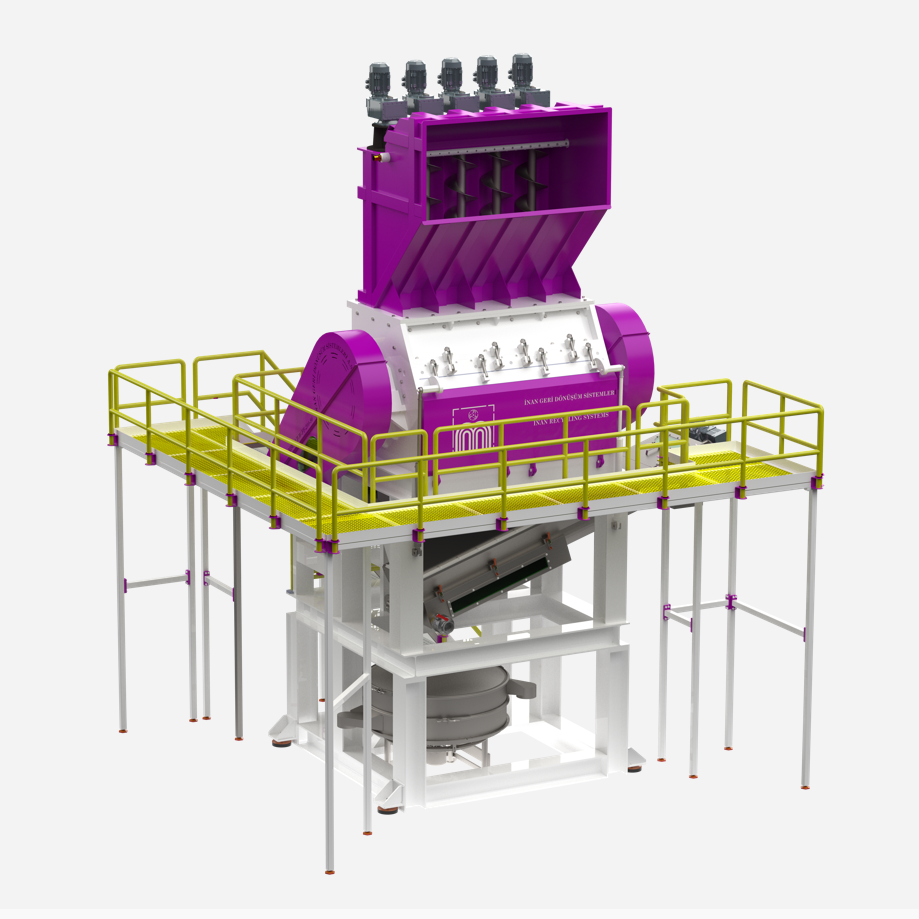

Multi-Blade crushing machines are suitable for high capacity size reduction of both hard and soft plastics such as PET, HDPE bottles, LDPE nylon, PP woven bigbags and sacks. It is widely used for the second step crushing of shredded pieces in soft plastics after the preliminary shredding process. 5 rotary rotor blade application is available. It works with high efficiency on all plastic materials, thanks to the rotor type, blade arrangement and sieve type selected according to the form and type of the plastic material to be crushed.

Turbo friction washing machines are one of the important machines used for cleaning the plastic flakes that are washed in washing lines at various stages (Wet Crushing, Floatation & Immersion, Separation Pools, Hot Washing Units, etc.). High speed rotating centrifugal separation rotor (1500-2200 rpm) provides high efficiency and cleanliness and dewatering by providing the centrifugal force without the need of any heat source, separating plastics from contaminants (sludge and other contaminant residues). These systems, which are widely used in recycling lines, can reduce the humidity level to minimum levels while maximizing the washing quality.

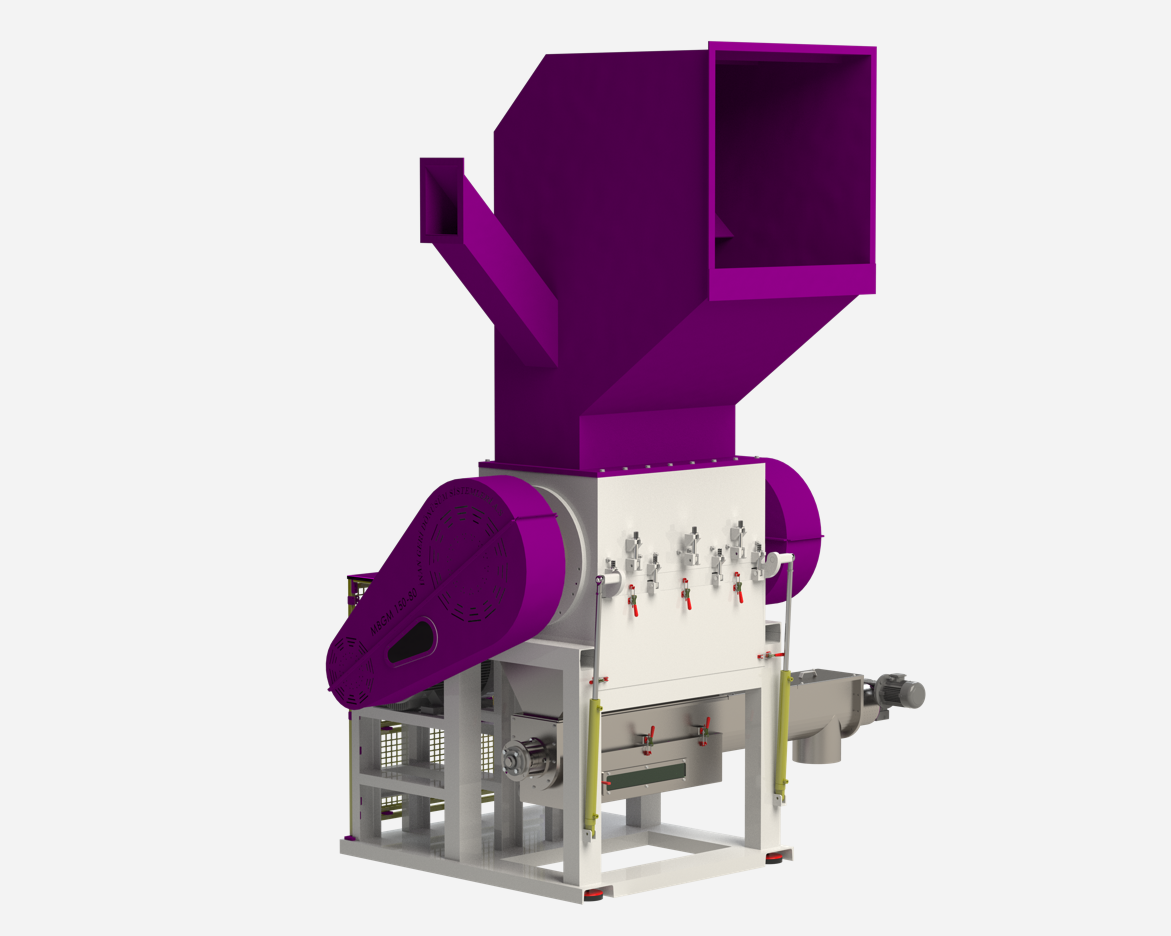

It is used to reduce the size of plastic wastes and scraps of different size and weight (PE, PP, PVC, PET, Rubber, ABS, PS, PC etc ...) by means of rotary and fixed knives. It works with high efficiency in all plastic materials thanks to the rotor type. High capacities are achieved with the special rotor structure. 3 rotary rotor blade application is available. Blade arrangement and screen type selected according to the form and type of the plastic material to be crushing. Heavy-duty crushing machines are ideal for crushing manufacturing scraps and large defective parts, injection products, blow molding products, thermoform waste and coils, and rough and long plastics in pipe and profile form in the plastic processing industry.

Disc micronizers are high-speed fine crushers used for micronizing hard and brittle plastics such as 8 mm size broken PE and PVC flakes or granules at the micron level. The plastic material is dosed centrally into the micronizing machine. The hard plastic entering the grinding chamber is ground between the rotating disk and the hard disk and turned into powder. The waiting time of plastic material between discs is very short. Cooling is provided from three points: the fixed disk, the high-speed rotating disk shaft and the center. In this way, the heat generated due to high friction is reduced and excessive heat accumulation on the material is prevented, preventing deterioration in the polymer structure. Adjustment of the discs is done from outside the body. Discs are easy to change.

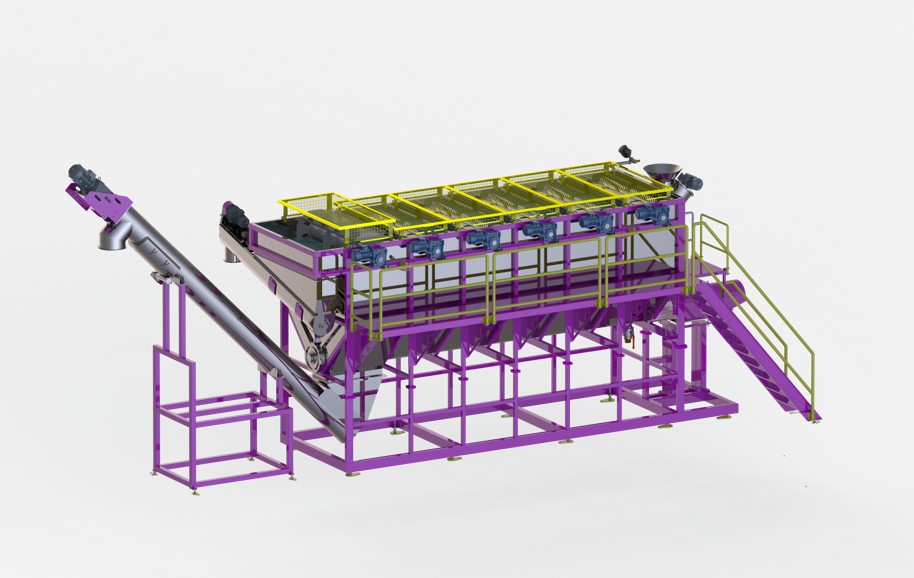

Pools used in washing lines are used for the plastics (PET, HDPE, LDPE, PP) after size reduction process; It is one of the most important separation units used to separate foreign pollutants such as dust, soil, sludge, stone, metal and paper. The mixed plastic is fed into the pool where the high density materials sink and the low density materials will float. As the material enters the separation pool, our specially designed rotary drums carry the material forward and with water. Ideally, we want the material to immerse in water longer. This not only allows the material to be further cleaned, but also allows all sinking material to have sufficient time to move to the bottom of the tank. Due to the density differences of plastics, different sizes of flotation & immersion, separation pools are manufactured for different types of plastics.

It is used to wash very dirty plastics for high quality product demands and to remove plastic from contaminants such as glue, label residue, odor, oil, food and beverage residues. Hot washing units have high washing performance with low energy consumption. Hot washing units used in washing lines are suitable for washing PET, HDPE, PP, LDPE etc. plastics.

Friction Washing machines washes dirty plastic materials under high speed (700 -1000 rpm) with pressurized water and provides deep cleaning with friction. Friction washing is used for cleaning both hard and soft plastic (nylon, bigbag). Thanks to the improved specially designed rotor and rotor blades, the friction is further enhanced and the efficiency of the centrifuge is increased. The screen placed inside the friction washing unit acts as a filter while separating the dirty water from the plastic. The dirty water is discharged by moving in the opposite direction and the plastic is transferred for the next process. It is used in washing lines for both product transfer and cleaning purposes. Friction washers are produced in different sizes according to the capacity. These systems, which are widely used in recycling lines, can reduce the humidity level to minimum levels while maximizing the washing quality.

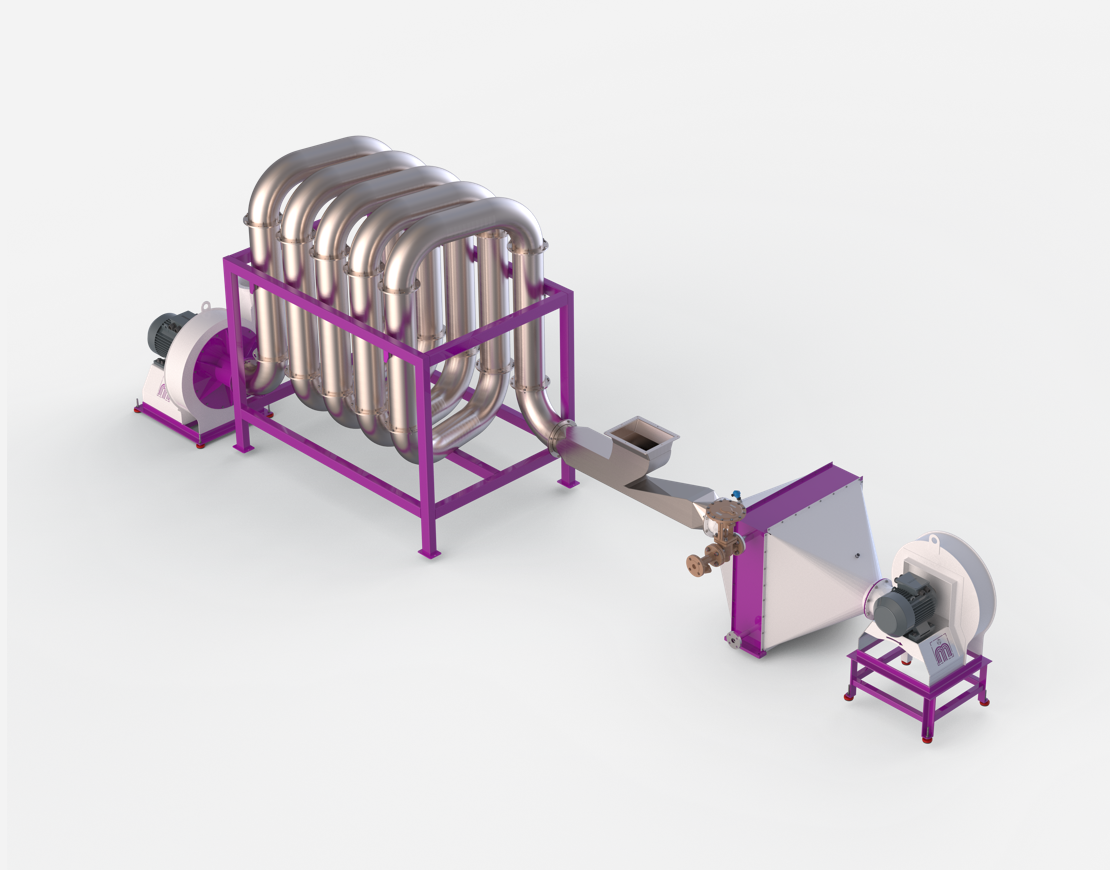

Hot air pipe drying system is the last dryer commonly used in plastic recycling washing line. Suitable for most plastic materials such as PET, PP, PE, etc.(Rigid flakes). After dewatering, the plastic flakes are vacuumed by a fan and conveyed by stirring with hot air advancing along a long spiral set of stainless steel tubes. With the cyclone at the end of the pipeline, moisture is expelled. The spiral tube increases the contact area between plastic flakes and pipes. This increases the drying rate as the plastic flakes passes through the pipes with hot air and reduces the final moisture to international standards. Low consumption, high efficiency, anti-corrosion, excellent performance, make the pipe drying system an ideal equipment for plastic recycling production.

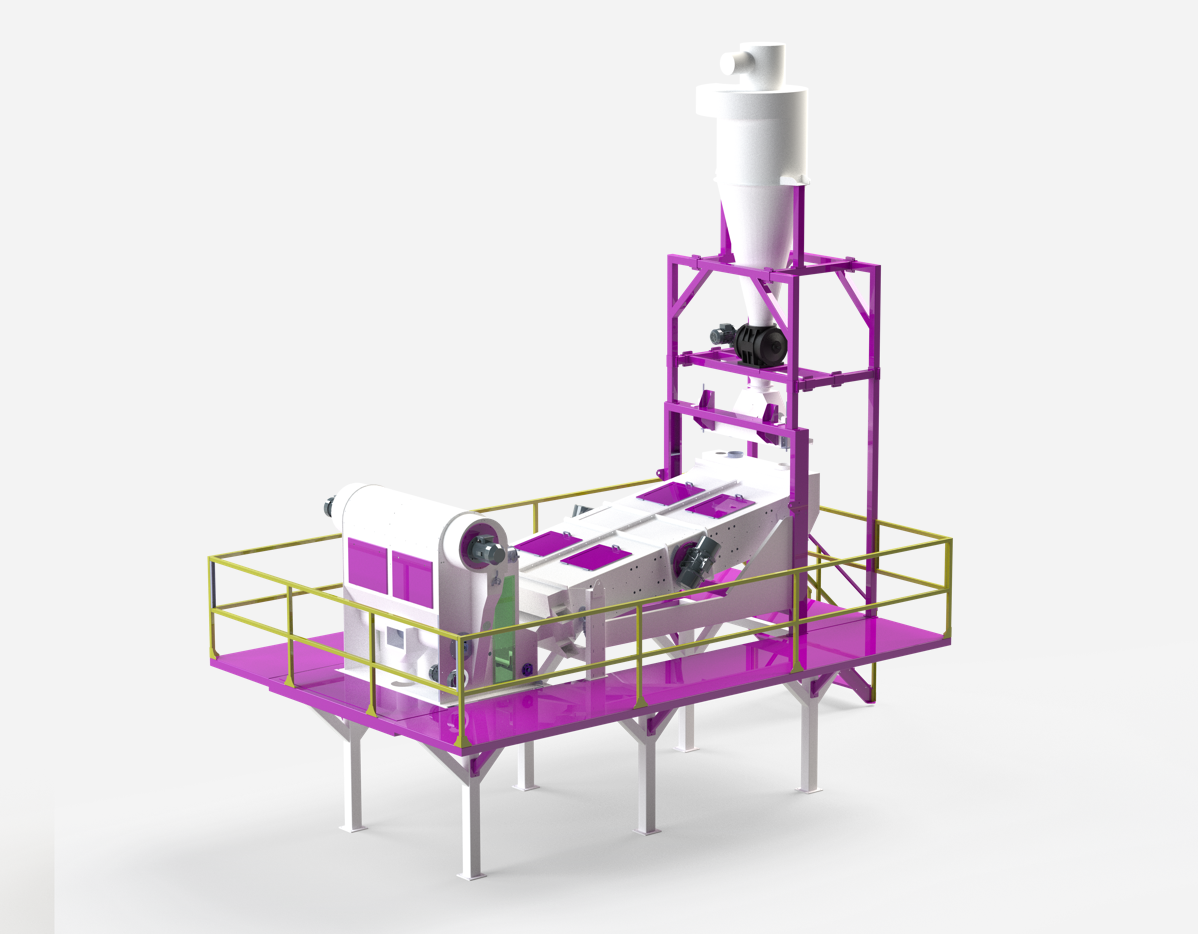

The dust and label separation unit is used to separate light label residues and plastic dust from plastics that are free of moisture and in the form of flake. Label residues and light pollutants in powder form that cannot be separated by conventional methods are separated from rigid plastic flake by vacuuming. It is extremely effective in achieving maximum polymer purity in the final product. Machine operates at high efficiency with its specially designed vacuum system and cyclone.

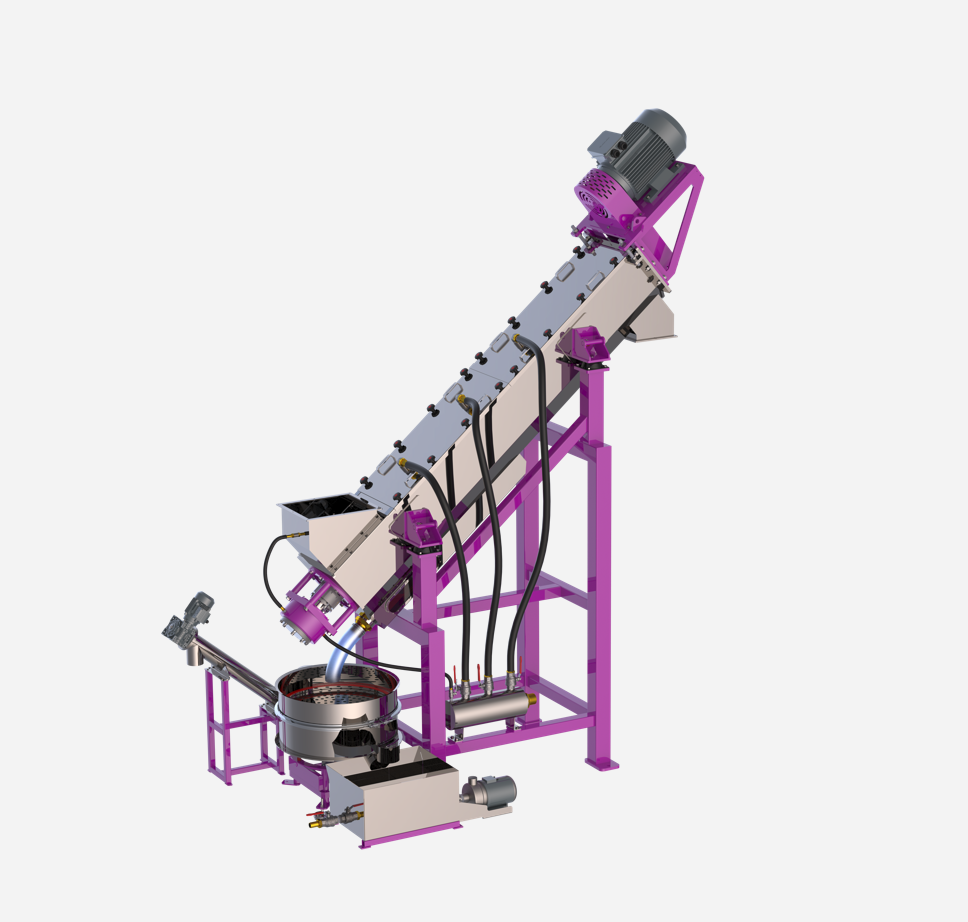

Vibrating screens are one of the most important screening machines used in the plastic recycling industry. Machine is used to classify plastic particles in the form of flake according to their sizes. Plastic particles fed from the vibrating screen inlet move forward on the screen wire at a certain speed through vibration and spread on the screen. At this stage, particles smaller and larger than the screen hole size are screened to obtain plastic particles in the desired sizes. The main product is transferred to the next unit of the line.

No represented companies found.

The company has no registered brand information.

TR

TR