| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

LEADER EXTRUSION MACHINERY IND. CO., LTD.

No.235, Sec.1, Gangbu Rd., Wuqi Dist. / / Taichung / TAIWAN

|

Contact Info: +886 4 2638 0888

|

Hall: 10

Stand: 1014A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

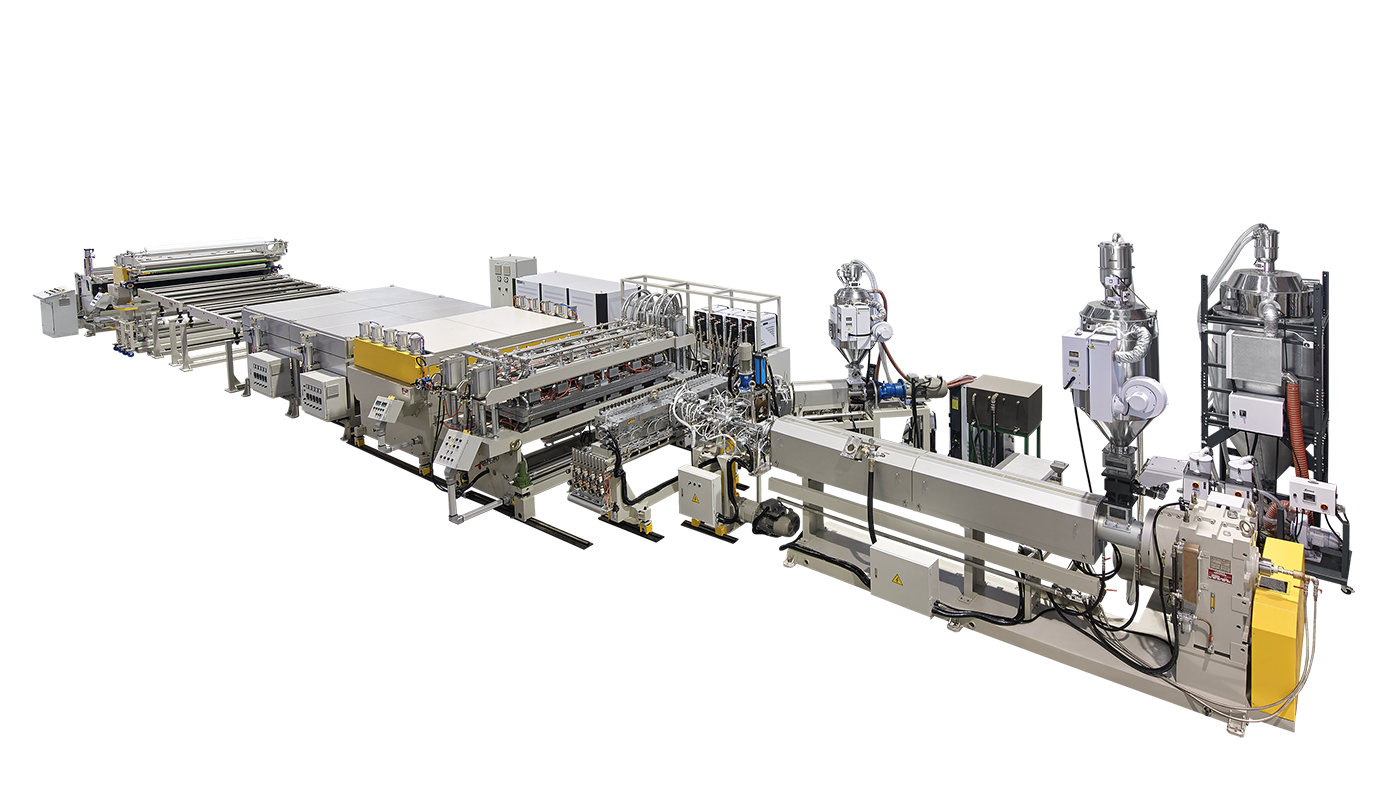

Leader Extrusion Machinery was dedicating in the manufacture of plastic extrusion industry for more than 30 years. We are able to meet customers various kinds of requirement base on our rich experience. We offer high quality machine, Leader extrusion machine from material to finished product; design to manufacturer is all made in Taiwan. To ensure the product quality, our factory has gained ISO-9001 certification and our products have passed CE certification. We also serve customer with customized machine and turnkey project.

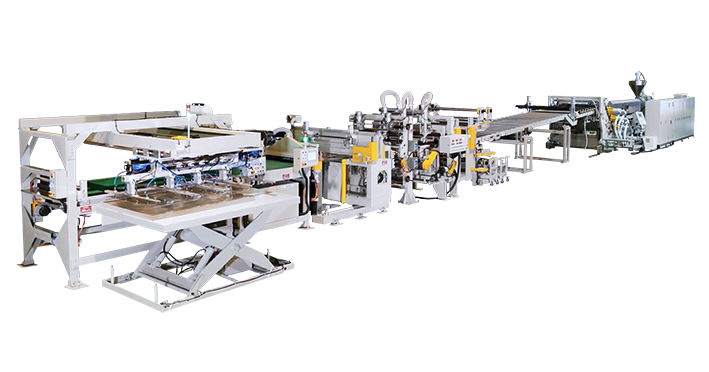

Hollow sheet extrusion production line is suitable for the production of hollow plates of various specifications, special screw structure, control of technical parameters, stable setting equipment, and precise temperature control system. The electronic control equipment effectively optimizes the whole line operation and achieves high quality and high output. PC hollow sheet has good insulation performance than other light-transmissive glasses, which makes it is the first choice for energy-saving and Light-transparent construction. Widely used in light covers, greenhouses, advertising signage, advertising lightbox, and so on.

Hollow sheet extrusion production line is suitable for the production of hollow plates of various specifications, special screw structure, control of technical parameters, stable setting equipment, and precise temperature control system. The electronic control equipment effectively optimizes the whole line operation and achieves high quality and high output. The feature of PP hollow profile has non-toxic, 100% recycled, lightweight, low-temperature resistance, waterproof and moisture-proof, corrosion resistance, impact resistance, energy absorption, and noise-blocking effect. Widely used in architecture for light partitions, building material protection boards, and packaging for aquatic vegetable and fruit packaging boxes, turnover boxes, etc. In addition, PP hollow sheets are colorful, printable, and processable that are also widely used in stationery, Card supplies, etc.

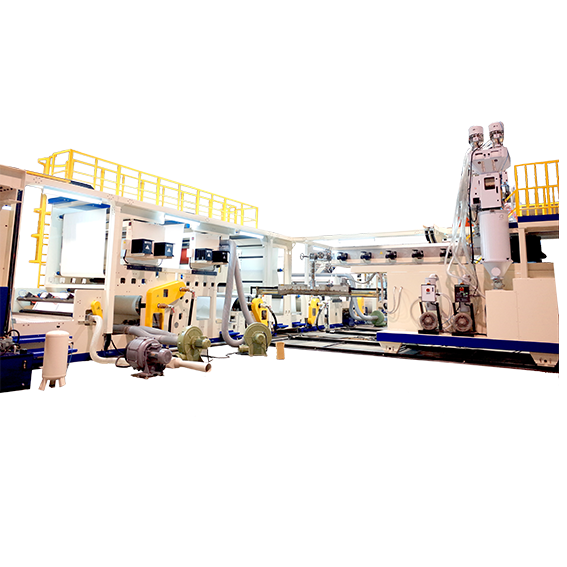

This line is designed for high temperature thermoforming applications, manufacturing thick plates, thin plates, various surface embossed plates and optical plates according to customer requirements. It can also produce wedge-shaped light guides, which are high-tech and high value-added equipment.

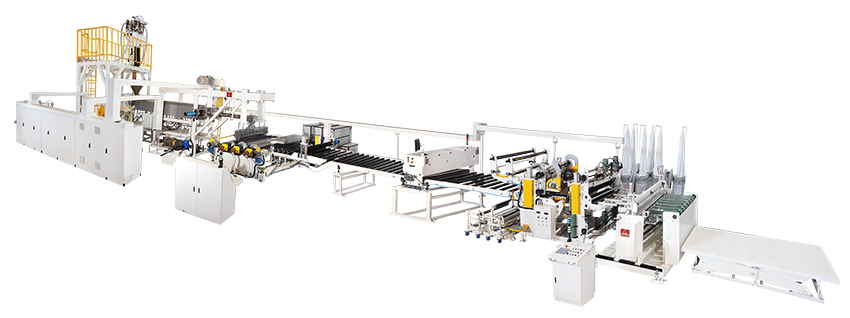

The transparency and barrier properties of PET sheets make them versatile in thermoforming applications. It is widely used in various blister/printing decoration fields such as toys, stationery products, panels, signs, handicrafts, water treatment, etc., as well as in the fields of pharmaceutical and food packaging containers

This model can produce optical PMMA sheet and impact resistance PC sheet. The optical PMMA sheet has excellent light transmittance, and high transparency, and it is not easy to change color after long-term use. It is widely used in various electronic instrument panels, touch panels, mobile phone screens, flat-screen TVs, light guide plates, diffusers boards, and so on. It also has characteristic of easy forming, it used in various of groceries and as decoration sheet. For example, reflective sheet for transportation, light cap for traffic light and furniture. PC sheet has excellent anti-impact, used in widely temperature range, high transparency and good anti-flaming. It also could coat UV layer to extend using time and reduce yellowing. It is used to apply in display window, skylight, lightbox and so on.

PP sheet is one of the most widely used industrial materials at present. The presses sheet has the characteristics of heat resistance, fire resistance, wear resistance, impact resistance, and corrosion resistance. It s generally used in acid-resistant sheds, cold storage partitions, and used as a compartment material board for dust factory engineering and special places.

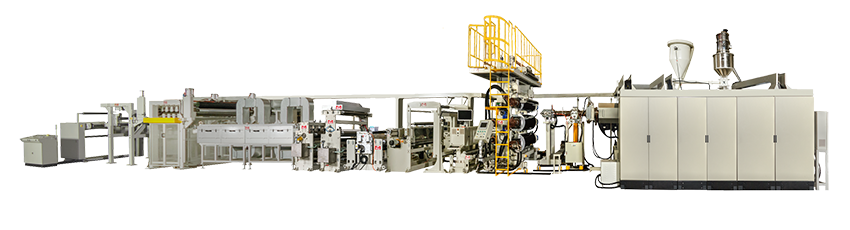

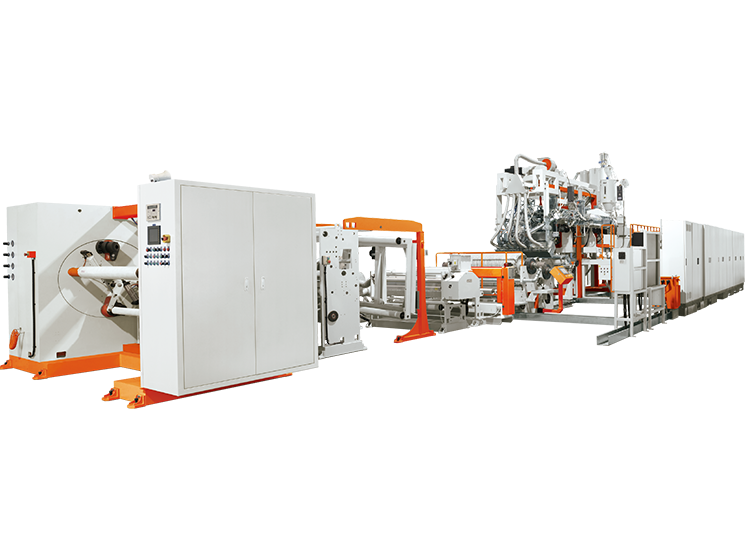

This production line is a multi-layer co-extrusion extrusion design to make the film flexible, and through the layering effect strengthen the layered adhesion, so as to improve the product tension. Multilayer films have been widely used in daily life and have brought great convenience to life. Functional films have unlimited possibilities in the application of materials, such as adding antioxidants, barrier agents, or laminating composite materials, which have light control, weather resistance, conductivity, barrier properties, antifouling properties, decorative properties, etc characteristics. Cast film has the advantages of high heat seal strength and low production cost, and its strength, gas barrier performance, and tearing performance are completely comparable to BOPP film. It can be used to produce packages, labels, and special packagings, such as heat-sealing film, synthetic paper labels, food packaging, pharmaceutical packaging, festive decorations, and sequins.

This line can produce TPU film with high transparency and high quality. The film produced can be used for optical applications. It s different from the traditional TPU film application in the market and is a high-grade TPU film production equipment.

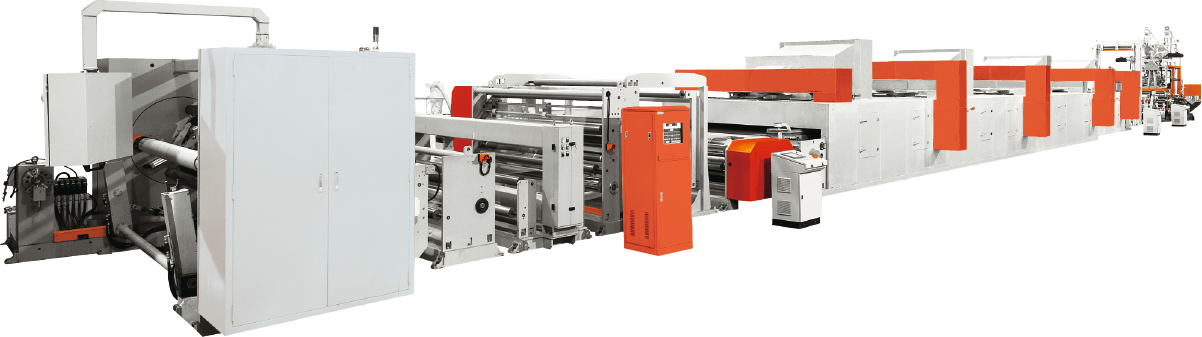

PET film has excellent mechanical properties, and its strength and toughness are the best among all thermoplastics. Its tensile strength and impact strength are much higher than ordinary films; it has good stiffness and good stability and is suitable for printing, paper bags, etc. PET shrink film is known for its excellent transparency and barrier properties. After bisynchronous stretching, film transparency is especially high. PET shrink film is used for generic packaging, labeling, special packaging (such as for DVDs), baked goods, keeping fresh fruits and vegetables, and synthetic paper labels.

This double-sided film extrusion equipment has mechanical high precision, high productivity, and high efficiency and economy. The winding station includes a surface rewinding and a fully automatic shaft switching system. The laminating machine offers a wide range of applications and processes, including single extrusion, double extrusion, and coextrusion lines. The machine offers many paper or film coatings, high quality, and stable lamination, which can be tailored to your needs. The film extrusion equipment is extruded and cast, and adhered to the surface of a flexible substrate such as paper or film after stretching, and is cooled and shaped to form a composite material having both plastic toughness and functional properties of the substrate. Widely used in woven fabrics, paper tableware, food packaging bags, etc.

No represented companies found.

The company has no registered brand information.

TR

TR