| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

MULTITECH PLASTİK MAKİNA SAN. VE TİC. LTD. ŞTİ.

Atatürk Mah. Adnan Menderes Cad. Aktim 2 Kıraç No: 15 İç Kapı No: 90 / Esenyurt / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 812 3225

|

Hall: 11A

Stand: 11A-113D

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

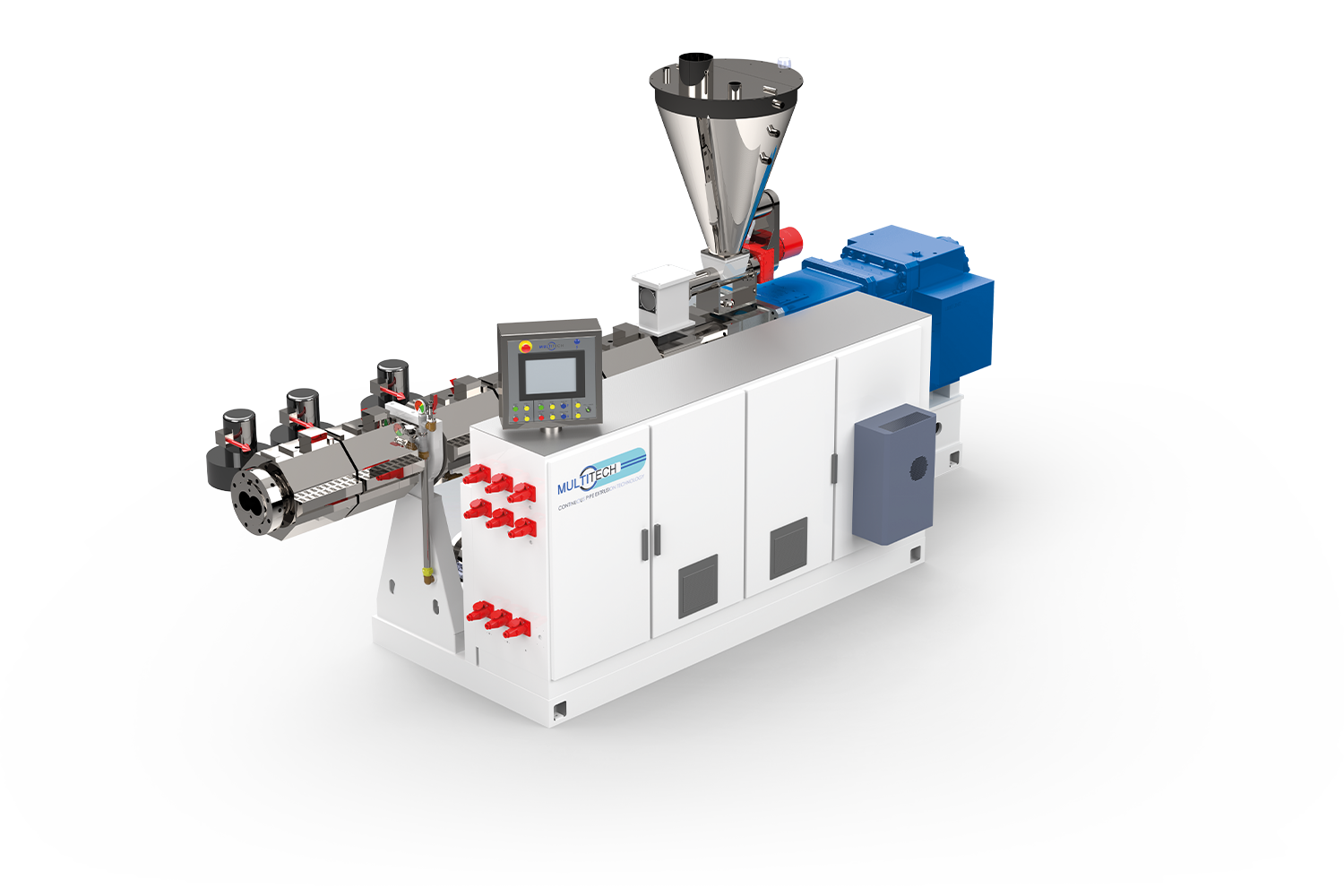

Multitech Plastic Machinery, High efficiency technological plastic extrusion machines and auxiliary equipments have been established to meet the international safety, quality and production standards by combining the power of three partners with 15 years experience in plastic machinery and engineering infrastructure. All of our designs, projects, productions and commissioning stages are carried out by our team. The best technologies are closely monitored and production is carried out using these technologies. Our company is engaged in research and development investments for the skirt to achieve excellence in product quality. The services provided by our company include the design of the infrastructure project for the manufacture of plastic pipes and profiles, the manufacturing of the necessary machines for the manufacture of these machines, the commissioning of these machines, the training of the personnel working in the machines and the commissioning of the necessary machines for the production, and the preparation of the production standards. The equipment we use is selected in full compliance with international standards.

Belling Machines Our machines are designed for belling of waste water pipes, electricity pipes and pipes (PP-PVC-PE) according to demand. It can belling in the length range of 150mm 6000mm. According to your requests, it can be belling up to Ø 32 to Ø 500 mm diameter. The socket structure can be belling according to international standards with inflation system or core expansion system. All electrical and pneumatic systems comply with international CE standards. Our machines are offered to the service of pipe manufacturers with three different models according to the line capacities in order to perform fully automatic belling on the line.

Single screw extruders are the best screw for maximum performance in PP and PE 100 pipe production. Our screws are manufactured from 8550 nitriding steel and are subjected to the most accurate and long-lasting nitriding process that determines the life of the screw barrel. Our screw sleeves are also produced with bimetallic coating technology.

Can be used for PVC Pipe Manufacturing.

Each extrusion line for the tube head is manufactured to meet the specific needs and process parameters of each material processed and the desired end product. All die heads for tubes are equipped with interchangeable pins and bushes to speed up gauge changeover and special coatings designed to optimise the flow of thermoplastic material.

Our vacuum tanks are made of stainless steel and are resistant to corrosion. The drive-controlled vacuum pump provides lower energy and power consumption with quiet and clear battery performance. Easy filter replacement and less maintenance maximises your vacuum performance. Thermoregulation valves provide efficient and low water consumption. Monoblock and double compartment vacuum tanks facilitate your pipe production. Spray nozzles with special conical design and different lengths provide effective cooling. Low Energy Consumption, High Performance

Produced from high-qualiy stainless steel material, used for cooling of the just extruded pipes with sprayed cold water.

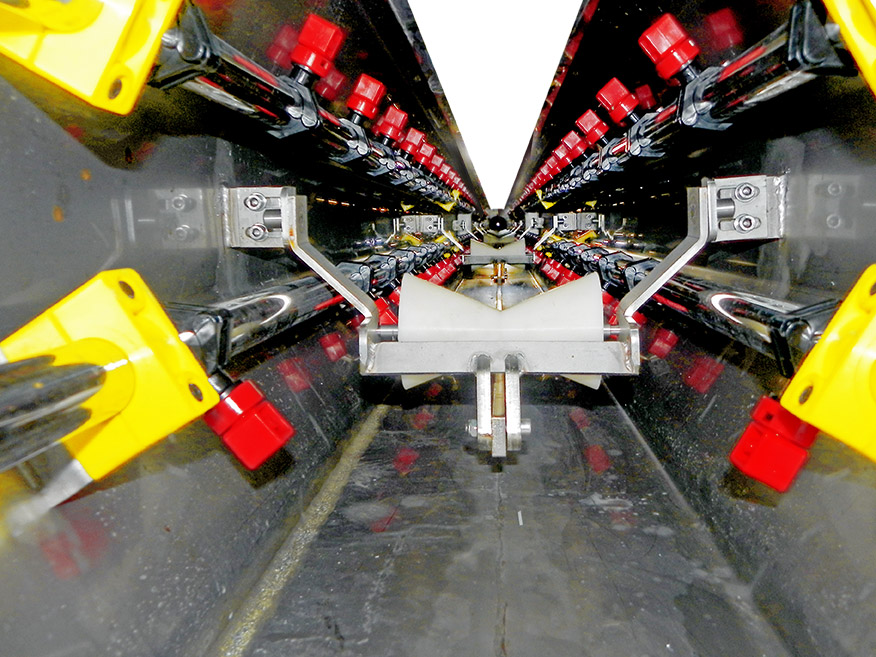

It is specially diaznised according to pipe diameters and wear-resistant special polyurethane coated belts are used in 2 pallet hammers. For 3 pallets and above, rubber coated pallet chains are used. With servo drives, pallet speeds provide maximum power even at very low speeds. The pallet contact surface varies between 0.75 m and 3 m. Individual motor control, communication and control with extruder Can be controlled by remote control The hammer pallets are designed to best grip the pipe. Upper pallets are provided with pneumatic regilation adjustable pistons for pressure adjustment. Mechanical motor driven adjustment mechanism is available on the lower tracks. In our hammers, the pipe is drawn in a precise form without vibration and interruption.

CUTTING WITH A KNIFE Ideal for HDPE pipes (polypropylene). This type of machine cuts without burrs and thus produces neither dust, chips nor noise. It grips the pipe with conventional clamp holding or universal clamp system. Developed for 16-1200mm HDPE and PPRC pipes. By attaching a chamfering device to this cutter system, a perfect chamfer can be obtained on PP waste water pipes. CUTTING WITH PLANER SAW Planetary saw system equipped with disc and milling cutter for cutting and chamfering PVC pipes or other plastic materials. It grips the pipe with conventional clamp holding or universal clamp system. It has a high flow rate dust extraction system. MULTITECH precision cutting saws are the perfect solution when high extrusion speed, short cutting lengths and small tolerances are required. The cutting carriage assembly is driven by a servo motor and drive. It moves together with the pipe being extruded. This enables precise and short multiple cuts. Developed for 16-1200mm PVC pipes. Rotary Type Cutters: Developed for Ø16-1200 mm HDPE and PPRC-C pipes. Saw Type Cutters: Developed for Ø32-1200 mm PVC pipes.

Our coilers designed for coiling pipes up to Ø 16- Ø 125 mm with our different models. Winding speed is provided with torque control and it can perform rigid winding. The winder arms are opened and closed pneumatically and when the arms are opened, the coil removal takes place comfortably. Servo motorised pipe guiding traves system and a precise winding is realised. Values to be entered from the screen according to the pipe diameter and the parameters change automatically from the PLC system. Our coilers work synchronously with pipe extrusion lines.

Multitech machinery manufactures PE-PEX-PVC-PP pipe calibers for plastic pipe extrusion lines. Calibers are made of special bronze alloy to minimize friction during pipe production. We offer special designs for each pipe extrusion line to reach the maximum pipe production speed. We have calibers adjusted according to the barrel classes. Minimized friction, maximum speed and performance, accurate calibration in accordance with measurement standards.

No represented companies found.

The company has no registered brand information.

TR

TR