| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

NM TEKNİK PLASTİK DEPO LOJİSTİK SANAYİ TİCARET LİMİTED ŞİRKETİ

HALKALI MERKEZ MAH. BASIN EKSPRES CAD. MITSUBISHI YILDIZLAR OTO PLAZA NO: 25/1 KAT:3 / KÜÇÜKÇEKMECE / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 503 2424

|

Hall: 11A

Stand: 11A-140G

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

WITH ITS MANY YEARS OF EXPERIENCE AND KNOWLEDGE IN PLASTIC WELDING TECHNOLOGIES, IT INCLUDES ALL KINDS OF PLASTIC WELDING TECHNOLOGIES AND IS YOUR BEST SOLUTION PARTNER IN PRODUCTION WITH A PROFESSIONAL APPROACH IN CONTRACTING MANUFACTURING.

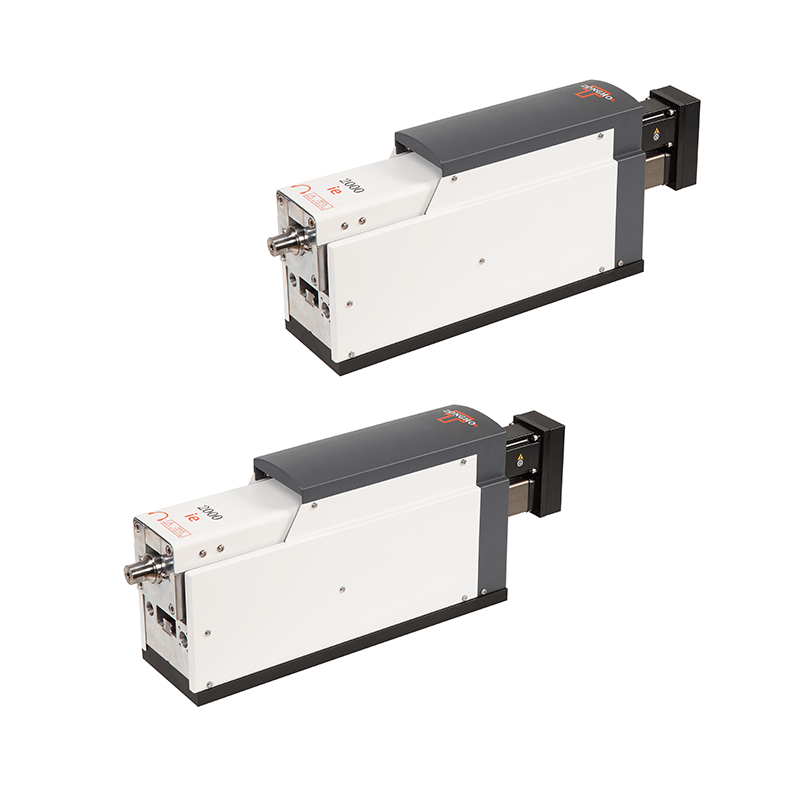

High Precision, Distance Control Digital Technology Fully Automatic Ultrasonic Plastic Welding Machine Multiple welding modes, time, energy and distance controlled welding system. Our touch color screen generators stand out with the future-oriented iQS operating system. Data connection with data collection internal scan page supports Industry 4.0 applications.

Digital Technology, Touch, Color Screen Fully Automatic Ultrasonic Plastic Welding Machine. ● 6th generation iQS operating system ● Internal scan page for data monitoring ● Welding parameters can be saved to USB ● Precise and Accurate Quality, Quality Control diagnostic control ● Automatic press lifting motor mounted for structural adjustment ● Modular structures with multiple welding modes ● Time, Energy and Max. Energy mode working system

Handheld Ultrasonic Plastic Welding Machine Intelligent control technology provides higher quality and sustainable welding quality. It has built-in time, energy mode that can freely program the beginning and end of ultrasonic welding. Touch Color screen, With digital generator technology Low weight, ergonomically designed handle Systems are available at 20kHz, 35kHz frequencies. With digital generator technology Easy to use by reducing operations.

Special production for professional production lines, Ultrasonic Welding Modules iTPS Series welding systems have an ultrasonic system that can be flexibly applied to special equipment Easy integration with special applications, systems and production lines; High repeatability and process reliability; High performance and benefits, low maintenance cost; Available for installation at the desired location, installation is easy and simple; Compact and narrow structure.

Dokunmatik Renkli Ekranlı Ultrasonik Jeneratör (Harici Kullanım için) GW-G serisi ultrasonik jeneratör kompakt yapıya ve 7 renkli geniş ekrana sahiptir, zaman ve enerji modlu kaynak ayar parametreleri jeneratörün menü öğeleri aracılığıyla ayarlanabilir ve kullanım kolaylığı modüler ekrandadır. Gerçek zamanlı frekans otomatik izleme ekranı ve USB diske verileri PC aktarma

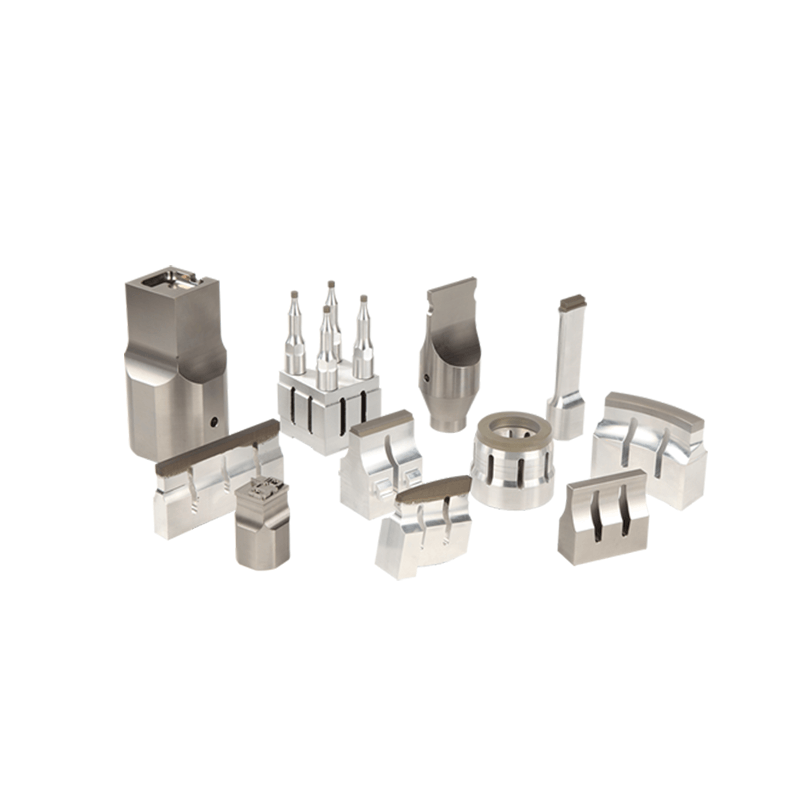

Ultrasonic Welding Molds (Welding Horns - Sonotrode) The quality of welding horns is an extremely important part of ultrasonic welding. In addition to the production team with many years of experience and expertise, our company has reached the same level as European and American manufacturers among the world s leading manufacturers by designing welding horns, which are the most important work of ultrasonic welding, using the latest digital simulation and analysis software. When the vibration system and basic technology of the welding horn are used in parallel with our other machines suitable for the most ideal design, ultrasonic welding quality will reach maximum performance. 15KHz, 20KHz, 30KHz, 35KHz, 40KHz available Can be manufactured from Aluminum, Steel and Titanium Materials. Various designs (round, size, block, carrier, trunnion, cutting etc.) Mechanical amplitude is available as 1, 1/1.2, 1/1.5 and 1/2 Lambda according to the design.

- DONGHO

TR

TR