| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

PULS ELEKTRONİK SİSTEMLERİ MAK. SAN. İÇ VE DIŞ TİC. A.Ş.

Ömerli Mah. Seciye Sok. No: 8 Arnavutköy / / İSTANBUL / TÜRKİYE

|

Contact Info: +90 506 632 5539

|

Hall: 7

Stand: 722

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Since 2002, Puls Electronic Systems has been dedicated to delivering high-precision industrial solutions, guided by our motto, We know the Load on you, because we can measure it. Based in Turkey, Puls Electronic combines innovative thinking with advanced electromechanical expertise to provide top-quality products for the machine industry. With a strong foundation in R&D, we offer a broad product range that has earned us a solid global presence in 86 countries, supported by a dealership network in over 28 countries. Our innovations in the weighing industry include groundbreaking achievements like the 100 mg precision Checkweigher, Crane Scales, 20-120kV Static Charger, and Web Cleaner. Today, we proudly present over 200 products across three main sectors Weighing Systems, Static Solutions, and Silo Equipment. Puls continues to set new standards worldwide, bringing advanced, customer-focused solutions to the plastics industry and beyond. We invite you to explore our latest advancements at Plast Eurasia İstanbul and see how Puls Electronic s continuous innovation and global expertise can elevate your operations.

Designed specifically for high-precision applications in the plastics industry, our gravimetric single screw dosing systems ensure flawless material dosing in production processes. The entire feeding system is mounted on a weighing platform, performing continuous weighing as the screw feeder operates at timed intervals. The system calculates the decreasing material amount in real time, comparing it with the target value. The motor adjusts the feed rate to maintain a steady, precise flow that meets the desired target. This synchronized control and correction mechanism maximizes dosing accuracy, keeping material flow within a narrow tolerance range. Especially effective for dosing plastic granules and powders, our system is ideal for manufacturers aiming to optimize quality control processes. Experience improved speed, accuracy, and quality with our dosing systems, designed to elevate efficiency in your production line. Visit us at Plast Eurasia Istanbul to discover how our solutions can enhance your operations.

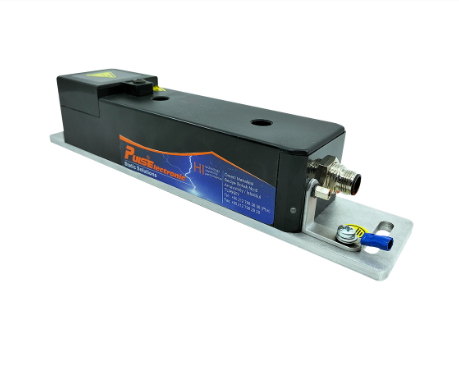

In the plastics industry, where high-speed production lines and stringent hygiene standards are essential, our HIPER Series Antistatic Bars provide a highly effective solution. Featuring next-generation design and a microprocessor-controlled power unit, these bars eliminate static electricity with precision, achieving up to 700 mm ionization range. This extended range makes them ideal for applications requiring remote mounting. Operating with just a 24V DC supply, the PULS HIPER antistatic bar generates high-frequency pulses, delivering reliable performance even at a distance. Free from air dependency, this system is a hygienic, safe, and sustainable solution for plastic processing and packaging lines. With a calibration-free structure and easy maintenance, the HIPER antistatic bar ensures long-term, uninterrupted operation at peak efficiency. The HIPER Series is the ideal choice for Plast Eurasia İstanbul attendees seeking a reliable static control solution for demanding production environments in the plastics industry.

At Plast Eurasia Istanbul, we will be showcasing IML (In-Mould Labeling) Technology, an integrated labeling solution for plastic injection products that enhances durability and aesthetics. Applied directly during molding, IML technology is ideal for food packaging, cosmetic containers, and industrial applications, producing labels that resist peeling, are environmentally friendly, and recyclable. It also saves time and costs by eliminating the need for a separate labeling process. Benefits of IML Technology: Durable Labeling: Embedded labels that resist wear and tear. Eco-Friendly: Recyclable, single-component products. Efficiency: Eliminates the need for extra production steps. Smart Charger is a compact high-voltage generator designed for temporary adhesion needs in the plastics industry. Operating with 24V DC and adjustable from 0-18 kV, it s perfect for close proximity use, even on robotic arms. Equipped with an M12 connector and removable electrode head, it offers remote control, along with arc and overcurrent protection for safe, long-term operation. For those seeking quality and efficiency in plastic production, IML Technology and Smart Charger are on display at Plast Eurasia Istanbul. Visit our booth to discover how these solutions can optimize your production processes.

At Plast Eurasia Istanbul, we are showcasing our RS1 Series Load Cell, PD-20 S Digital Load Cell Signal Transmitter, and HGX1300 Panel Mount Load Cell Indicator ideal for companies aiming to enhance precision and reliability in plastic production. The RS1 Series Load Cell is designed for tension control on winding and unwinding reels, featuring a durable aluminum body with anodized coating for longevity. The PD-20 S Digital Transmitter converts load cell data into digital format for seamless integration into existing systems. The HGX1300 Indicator is suited for panel mounting and provides real-time data for efficient weight monitoring, enhancing overall process efficiency. These products offer dependable solutions for tension and weight control in the plastics industry. Visit our stand at Plast Eurasia Istanbul for more details on how they can support your production needs.

At Plast Eurasia Istanbul, we will showcase the PULS Web Cleaner, a compact system designed to quickly neutralize static electricity on surfaces and remove dust and particles. This contactless cleaning technology effectively eliminates unwanted particles, including visible and microscopic dust and dirt, from statically charged surfaces. By lifting particles from the surface and securely trapping them in a sealed chamber through vacuuming, the Web Cleaner ensures a high standard of hygiene. Equipped with the latest PULS Antistatic bars, the Web Cleaner delivers high-performance cleaning in sectors such as packaging and printing, effectively cleaning surfaces on materials like plastic, glass, and packaging products. It prepares surfaces before printing to enhance print quality and supports winding efficiency in production processes. For applications where hygiene is critical, such as food packaging, the Web Cleaner prevents contaminants from coming into contact with the surface of the plastic, thereby protecting the hygiene of the packaged contents. The PULS Web Cleaner is an ideal solution for professionals in the plastics industry looking to achieve precise surface cleaning, improved print quality, and secure hygiene standards. Visit our experienced sales engineers at the fair for more details and to explore tailored solutions for your needs.

At Plast Eurasia Istanbul, we re excited to present the PCW Combo and PCW-1 Checkweigher Automatic Weighing Systems, developed to enhance product safety, quality, and operational efficiency for the food, beverage, and plastics industries. The PCW Combo features an integrated metal detector, automatically removing products with detected metal contamination, ensuring high-quality standards and delivering safe products to end consumers. Its stainless steel construction and robust industrial design provide long-lasting durability with easy maintenance. The user-friendly 7-inch touchscreen interface allows detailed reporting, and four reject system options piston pusher, air blower, separation arm, and drop-down conveyor boost operational efficiency by adapting to various product needs. The PCW-1 Checkweigher performs precise and automatic weight control for both packaged and unpackaged items in the plastics industry, supporting quality assurance with high accuracy and uninterrupted operation. With a durable build and easy installation, it ensures reliable long-term performance on production lines. These solutions are ideal for companies in the plastics industry seeking to improve quality, boost customer satisfaction, and optimize productivity. For more information, visit our stand at Plast Eurasia Istanbul or explore our website. Proudly produced in our Hadımköy factory, all Puls checkweighers come with dedicated after-sales support from our expert team.

At Plast Eurasia Istanbul, we will showcase our Static Electricity Charging Power Supply, engineered for high-voltage industrial applications and DC-powered bar systems. With adjustable output voltage from 0 to 20 kV and current up to 1 mA, this power supply provides flexibility to meet various operational requirements. Easy-to-set parameters from the front panel ensure a stable and reliable operation process. Equipped with remote on/off and voltage adjustment capabilities, the power supply enhances operator control and is available in both positive and negative polarity options. The easy installation and 180-degree rotating front panel simplify setup and improve usability. Featuring digital output adjustment and 4x HV output options, this device integrates all essential functions for high-voltage applications and DC-powered bar systems in one compact solution. Our Static Electricity Charging Power Supply stands out as a dependable solution for high-voltage applications in the plastics industry. We invite you to visit our booth at Plast Eurasia to explore this innovative product and learn how it can benefit your production processes.

At Plast Eurasia Istanbul, we will present our Rotary Paddle Type Level Sensor, specifically designed for accurate monitoring of solid materials such as powders or granules in silos or bunkers. The sensor s rotating paddle spins freely when no material is present. As the level of powder or granules rises and restricts the paddle s movement, a mechanical switch engages, cutting power to indicate that the desired fill level has been reached. This durable and reliable level sensor is ideal for production facilities managing plastic granules or similar solid materials. It ensures continuous monitoring, supporting uninterrupted production and automatic fill level tracking without operator intervention. For those looking to enhance their silo and storage solutions, our Rotary Paddle Type Level Sensor offers a highly efficient solution, especially for applications in the plastics industry where precise material control is essential.

At Plast Eurasia Istanbul, we will showcase the Puls Perforation Detector, a high-precision device developed for detecting perforations in the packaging industry. Designed to identify tearing perforations in bag production lines, it enables automatic counting and significantly enhances efficiency with its ability to detect up to 900 perforations per minute. The device offers an adjustable output voltage between 6kV and 21kV, easily controlled via the adjustment knob on the front panel. During perforation detection, the counting LED flashes to alert the operator. The Puls Perforation Detector is mounted onto the application surface with a high-voltage bar or single-pin probe. When arcing occurs from the bar to the ground through a perforation, the device generates a 30 ms optocoupler pulse, ensuring fast and reliable perforation detection. This device stands out with its easy installation, long operational life, and cost-effectiveness. It has a broad range of applications, including automatic counting in bag production, micro-crack detection in plastic tubing, perforation detection in thermoform sheets, plastic cup and PET production, tear detection in plastic raw materials, and perforation detection in appliance hoses. The Puls Perforation Detector is an ideal solution for professionals looking to enhance quality control processes in the plastics industry, offering high precision and user-friendly operation.

At Plast Eurasia Istanbul, we will showcase our Anti-Static Power Supply, a reliable power unit designed to operate seamlessly with anti-static ionizing bars, air guns, and blower nozzles, specifically engineered to eliminate static electricity. This unit delivers the high voltage required for active ionization devices, offering rapid setup and easy operation. Low-maintenance and efficient, this power supply can support multiple anti-static eliminator bars simultaneously, with a recommended total bar length of no more than 4 meters. The Puls Anti-Static Power Supply is equipped with a safety protection board to ensure secure operation. This protection board cuts off current in case of short circuits in the high-voltage cable or ionizer, thus extending transformer life and maintaining safe operation. Additional features include galvanic isolation and magnetic current limiting to enhance network safety, and the unit s fully grounded metal casing prevents electromagnetic emissions. CE-certified, this power supply is built to meet industrial standards. Compatible with products such as Anti Static Air Nozzles, anti-static bars, Anti Static Elimination Bars, high-voltage static eliminators, and Anti Static Air Gun, the Puls Anti-Static Power Supply offers a safe, efficient, and durable static control solution ideal for plastic industry professionals looking to improve production processes.

No represented companies found.

The company has no registered brand information.

TR

TR