| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

QINGDAO HEGU WOOD PLASTIC MACHINERY CO.,LTD

THE WEST END AND SOUTH SIDE OF YANGZHOU ROAD, JIAOZHOU CITY, QINGDAO, CHINA / QINGDAO JIAOZHOU / QINGDAO / CHINA

|

Contact Info: +86 150 6392 3327

|

Hall: 10

Stand: 1005J

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

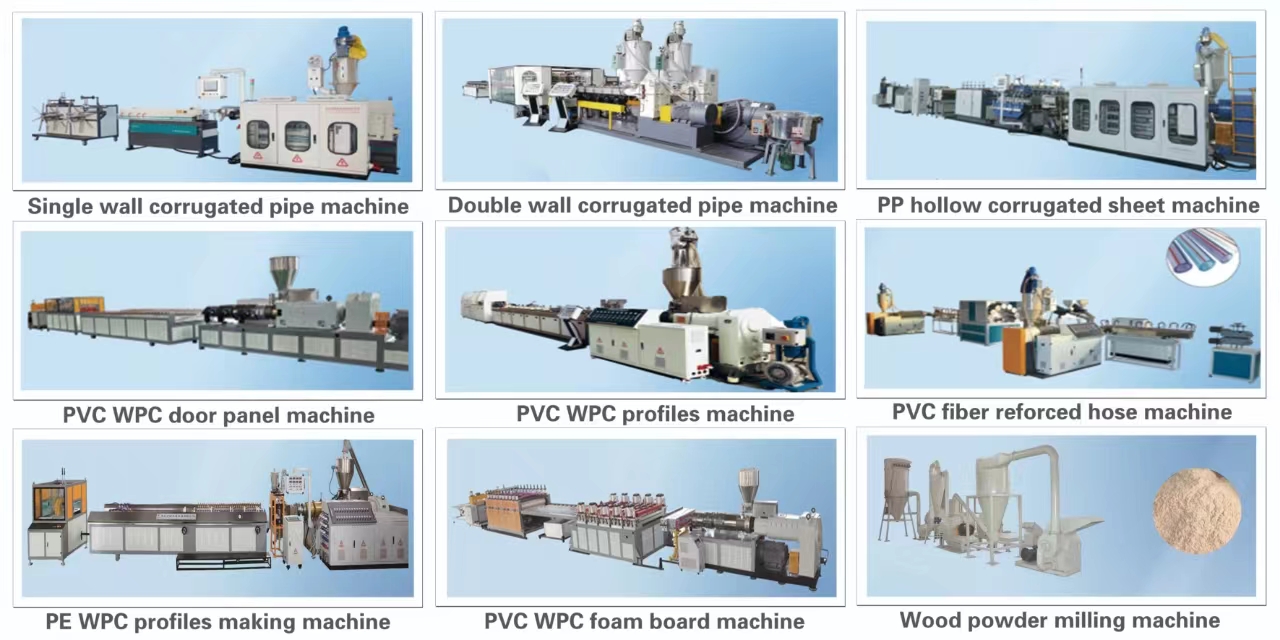

Qingdao Hegu Wood Plastic Machinery Co., Ltd. was established in 1997 as a professional Plastic machinery manufacturer, situated on the prosperous Jiaozhou bay, is exclusively specializing in designing and manufacturing a great variety of plastic machinery. With national scientific manpower, our company is engaged in the researching of late-model plastic machinery, the conversion of the international advanced technology and cooperation with the research institutes and universities to provide plastic machinery with high performance and high technology. The main product of our company is PP Hollow Sheet Extrusion Machinery,Plastic single wall corrugated pipe machinery, Plastic double wall corrugated pipe machinery, P E water supplying pipe machine, P V C water supplying pipe machine, recycled plastic pelletizing machine, W P C profile machine, W P C board machine, W P C foaming board line. And our Products have Obtained CE Certificates. For the future, Qingdao Hegu proposes the development strategy of making a priority to develop international business, comprehensively promoting domestic business to face the two markets, employ two kinds of resources, change development mode, and promote transformation and upgrading, and in creating customer satisfaction projects, to maximize shareholders benefits and pursue the growth of both organization and staff. All the staff of our company adheres to the principle of trust is root, client is god, high quality is first, service is best that we want to do business with the people all over the world on mutual be

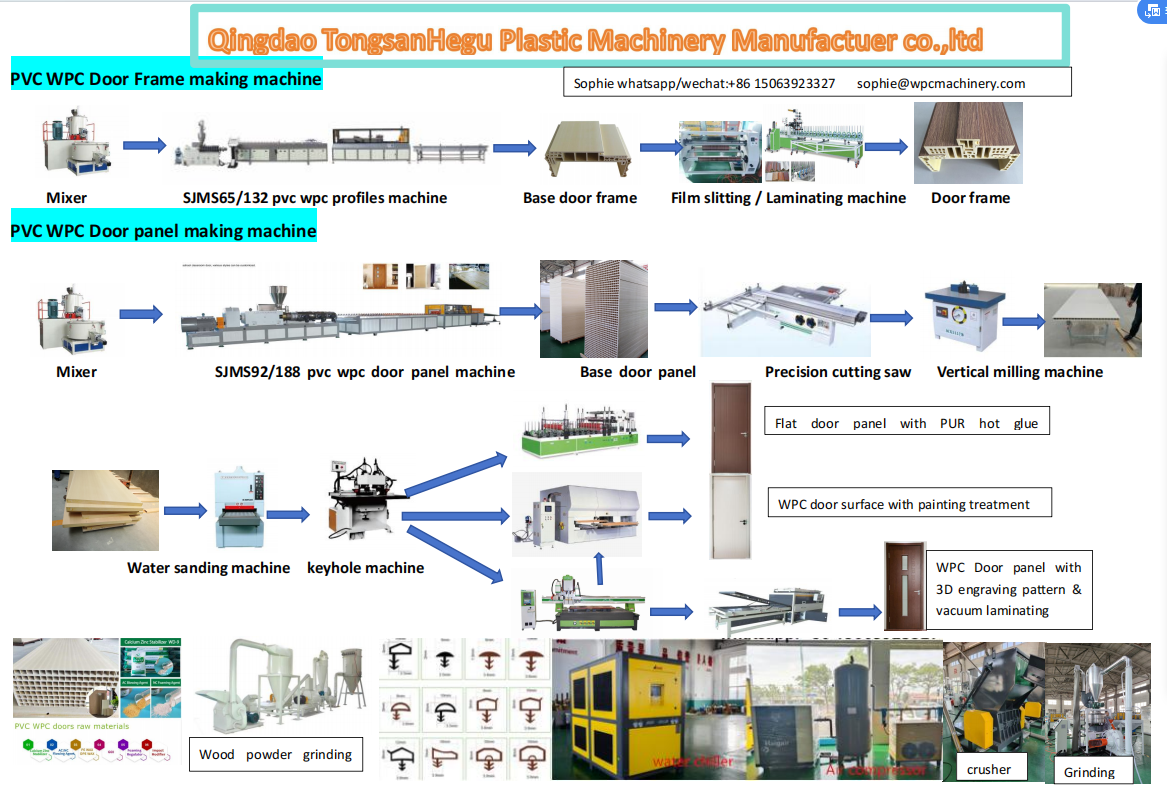

Qingdao HEGU is professional for the Whole WPC production line with turnkey Project Service since 1997. We have different type of WPC machines to make different WPC products from different raw material,such as: 1, PP PE WPC profile machine : Material: recycled 30% PP/HDPE+70% wood powder+chemical additives. Product: WPC decking, WPC wall cladding, WPC fence, WPC pergola.WPC louver. 2, PVC WPC profile machine: Material: 50%PVC+20% wood+20% caco3+ Chemical additives. Product: WPC door frame, WPC wall panel, WPC decoration profiles indoor. 3, PVC WPC door machine : Material:50% PVC+20% wood+20% caco3 +Chemical additives. Product: Hollow Door pane l, Cabinet Door, and other big profiles 4, PVC WPC board machine : Material: 60% PVC+10% wood +20% CaCo3+ Chemical additives. Product: Solid door panel, Furniture board, partition wall panel, decoration solid panel. 5,UPVC window profiles and panel making machines: Material: 40% PVC+50% CaCo3+ Chemical additives. Products:UPVC windows and doors,PVC ceiling,PVC wall panel,PVC rain gutter,PVC profiles.

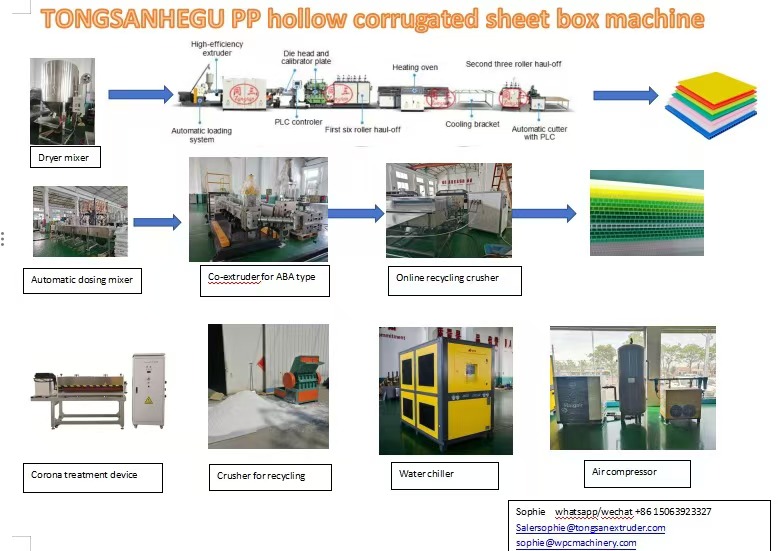

Tongan plastic hollow corrugated sheet production line realizes continuous production of PC/PE/PP hollow grid plate, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packaging box. PE/PP hollow corrugated sheet is an ideal substitute for carton box in making packaging box. It is characterized by light weight, high intensity, dampproof, and anticorrosion. Tongsan have all series high quality PP hollow corrugated sheet machine ,the width of the products is 1220-3150mm, and the thickness is 1mm-12mm.The extrusion line can reach 2-10m/min, the high capacity at 200-600kg/h. We provide high out production line with professional technology support,and auxiliary machine for package box making machines. We have customer in Iran, Dominia, Mexico, Ecuador,Czech Republic, Uzbekistan, Vietnam,India etc.We have won praise from customers for the quality of our machines and service. Tongsan continues to innovate with the industry s leading level.Looking forward to working with you for a win-win cooperation. Any need please contact me freely,my whatsapp is 0086 15063923327,my email is salersophie@tongsanextruder.com.

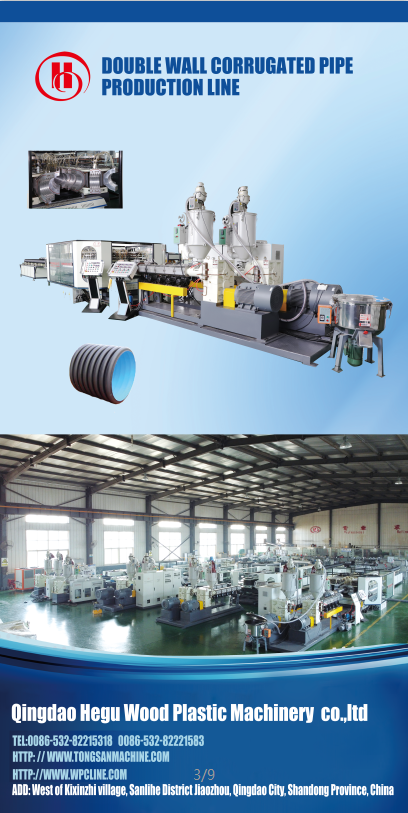

Qingdao HEGU professional for plastic corrugated pipe machine since 1997. The controller with Siemens PLC, easy to operate. Forming machine adopts gear high-speed drive mold block. Automatic lubricating oil system to ensure stable operation. Different types extruders for PP, PE, PVC, nylon, EVA. High speed corrugated pipe machine can reach 30m/min. Tongsan provides good quality machines and best service for you. Our Main Products are: 1, Wood Plastic WPC Decking Profile machine 2, WPC Door Making Machine 3, WPC Board Making Machine 4, Plastic Corrugated pipe machine 5, PP hollow sheet making machine 6, plastic sheet extrusion machine 7, PE PVC PPR pipe extrusion machine If you have any interest about our machine, please kindly feel free to let me know. My whatsapp +86 15063923327,my email is sophie@wpcmachinery.com .

SBWG-315 double - wall corrugated pipe production line can continuously produce HDPE double - wall corrugated pipe and this line can achieve on-line belling. The machine has the function of automatic demoulding when power is off. The extruder adopt high-efficiency screw, the die head adopts double-layer spiral structure, mould die and core die being nitrided , The forming machine adopts vacuum forming type, equipped with automatic lubrication system.Forming mould is made of aluminium alloy, adopt water cooling type. The pipe can be cut by on-line cutting machine automatically.

SJHB/SJFHB series plastic sheet/board production line can continuously produce PP/PE/ABS/PS/HIPS/PMMA material sheet/board, The sheet/board widely used in home appliances, sanitary ware, automobile and other industries.Different material sheet/board, use different extruder (exhaust type or non-exhause type). The machine equipped with non-stop screen changer, T-type die head and melting pump. To ensure the stability of raw materials and uniformity of extrusion .The three rollers calendar and haul off machine equipped with servo motor.The material of haul off roller is NBR.Machine can equipped with guillotine cutter or cutting machine according to different plate thickness. Using servo motor meter counter or rotary encoder meter counter. HGMSX series profile production line can continuously produce PVC/WPC profile,such as door and Window, wall panel, skirting etc.The production line consists of extruder, mould, calibrating platform, haul off and cutting machine and stacker.The extruder can produce PVC and WPC material profile by changing screw and mould.The calibrating platform adopts two-section structure and adopt double water tank, to ensure the stability of machine in production.The haul off and cutting machine is one body structure, the advantages of this unit are saving space and high precision cutting ,this unit also equip with dust collection system.The production line can optionally equip with PLC.

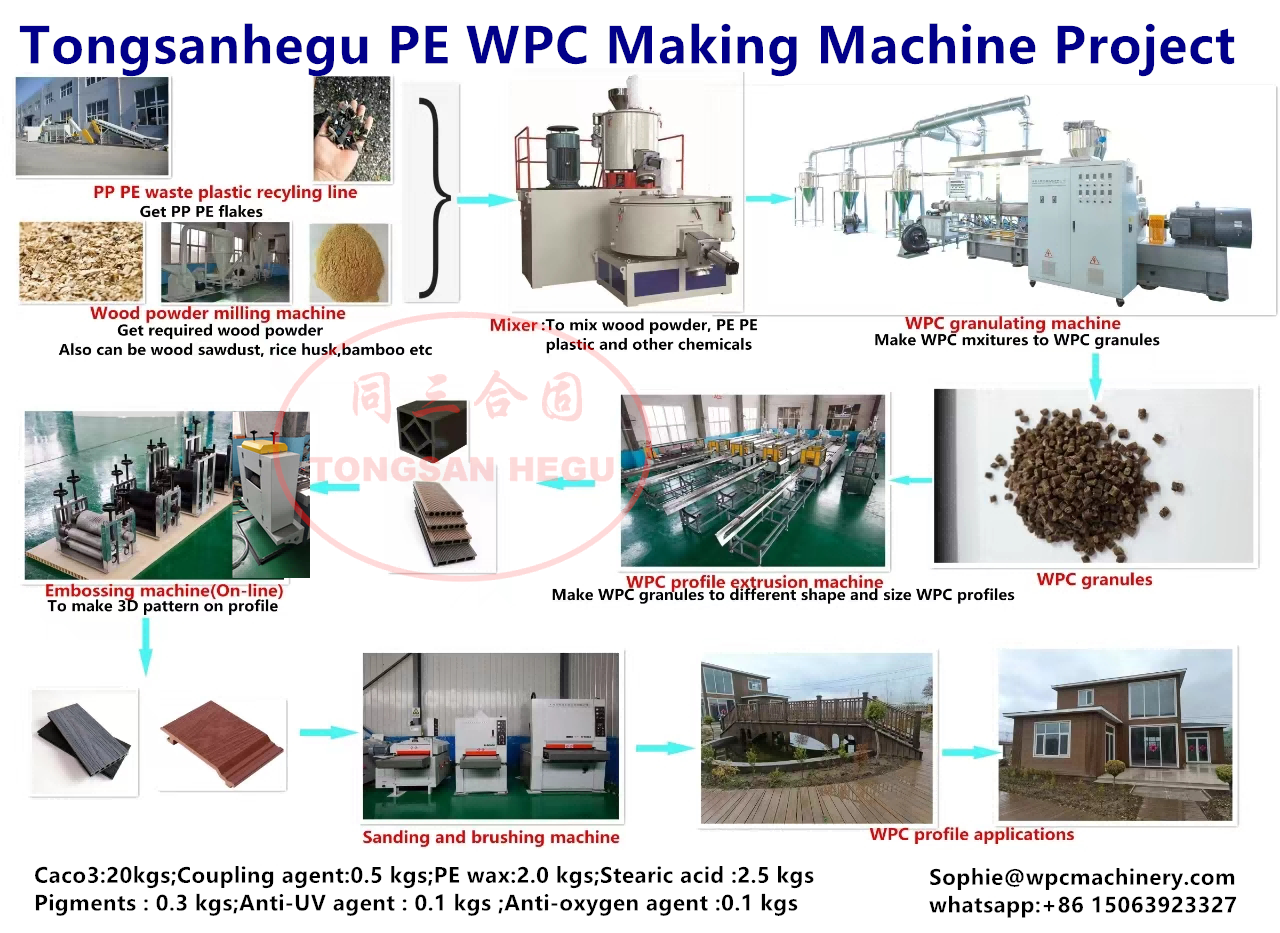

The PE WPC profile extrusion line is suitable for producing the hollow/solid PE WPC profiles. This profile has the advantage of fireproof, waterproof, moisture proof, moth proof, mildew proof and environment friendly. It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes, outdoor landscapes, pallets etc. HGMSE series PP/PE WPC profile production line can continuously produce PP/PE WPC profile. The WPC profile adopts two -step production process. The granulating machine make WPC pellets using PP/PE recycled materials, wood powder and auxiliary agent. Then use this production line produce WPC profile.Customers can choose embossing machine for the production line to achieve 3D pattern performance.Customers can also make PE WPC single color or double color co-extrusion profile by adding extruders.The profile produced by this production line can be sanded and brushed by sanding machine and brushing machine.

PVC WPC door panel extrusion line is for producing preparatory PVC WPC door panel. We can provide the turnkey project for integrated door panel and door frame. The whole production line includes the PVC WPC door frame extrusion line. WPC door panel extrusion line and subsequent processing equipment. The PVC WPC door has the advantage of fireproof, waterproof, anticaustic, moisture proof, moth proof, mildew proof and environmentally friendly. The PVC WPC doors can be widely used in interior doors, hospital ward doors, school classroom door, various styles can be customized. The PVC WPC profile extrusion line is suitable for producing hollow or solid PVC WPC foaming profiles. This profiles have advantages of fireproof, waterproof, anticaustic, moisture proof, moth proof, mildew proof, non-toxic and environmentally friendly. The profiles are widely used in the fields of interior decoration, furniture making, such as door frame, skirting, photo frame, plastic door and window profiles.

SJPEG Series Plastic Pipe Extrusion Line can produce PP/PE/PPR material single layer and multi layer pipes continuously. Extruder equipped with special designed screw for polyolefin . It has the features of high capacity, even plasticization, stable extrusion. Mould adopt spiral structure,processed from 45# forged steel. Calibrator is made by copper alloy, surface is fine finish and high hardness. The caterpillar of haul off machine is made of silicone synthetic material, which has high friction and durability. SJPVCG Series Pipe Extrusion Line can produce PVC/CPVC Pipes. This PVC Pipe Production Line is consists by conical twin screw extruder,mould,vacuum calibrating, tank-water spraying tank,haul off machine,cutter,stacker Extruder and Haul Off Machine adopt AC frequency speed regulator. Mould is processed from SC 45# forged material. Mould inner wall is chromed, surface is smooth. Haul Off machine could use 2 caterpillar, 4 caterpillar etc according to the pipe diameter and wall thickness Cutter could use saw cutting and planetary cutting, equipped with meter counter. The machine has reliable performance and high production efficiency. By changing extra mould or extruder, this machine could also produce spiral wall pipe, hollow wall pipe, and foam core layer pipe.

No represented companies found.

- HEGU

- TONGSAN

- TONGSANHEGU

TR

TR