| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

RENK MASTER PLASTİK VE KİMYA END. SAN. VE TİC. A.Ş.

Ikitelli OSB.Mah. Hurriyet Blv. S.S. Deparko Sanayi Sitesi Sade Plaza 1/44 No. 5 Zip:34490 / Başakşehir / İSTANBUL / TÜRKİYE

|

Contact Info: +90 212 675 1110

|

Hall: 2

Stand: 206A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Renk Master Plastik is one of the growing masterbatch manufacturers in Turkey, as the young and dynamic brand of the industry in the manufacture of masterbatch. As the main production of our company, which was established in Istanbul İkitelli, in a closed area of 7000 m2, engineering compounds and concentrated plastic paint production; It consists of 4 types as product which are color, black, white, compound and additive masterbatches. Our high quality, fast and innovative products are prepared with meticulous studies in line with the demands of our customers, whom we aim to be solution partners. We offer permanent and creative solutions to the needs of businesses with our R&D, Quality Control and New Color Studies. Our experienced colleagues,, production technology and wide color archive we have accelerate our sustainable growth rate in the sector of plastics. We serve with our colors to companies that produce in many variety of sectors such as automotive, defense industry, white goods, small household appliances, cosmetics, cables, glassware, household appliances, toys, garden and office furniture. We aim to continue to grow by offering our customers the best service and products with a competitive price policy. We believe that the secret of our success based on quality management is sustainable with unconditional customer satisfaction.

Our Color Masterbatches have high pigment rate. It has excellent dispersion, high heat resistance, high light fastness performance and bright. This product, which can be made to include fluorescent, pearlescent and gilding effects, has different pigment ratios. Usage Areas: Kitchenware, blow molding group, automotive sector, household goods, toys, agricultural products, pipes and fittings, electrical / electronics, injection group, as well as all engineering such as PS, SAN, ABS, PC, PA, PET includes plastics. In line with the demand, all products are produced and shipped in the fastest time with high quality

Our black masterbatches have a high carbon ratio. It is economical as well as perfectly dispersed, matte and glossy and resistant to high temperatures. This product, which can be made to be opaque and transparent, is more than 25 percent, It has different carbon ratios up to 50 percent. In line with the demands of our customers, we can quickly meet the demands with high coverage, high dispersion and high concentration. Areas of Use; Packaging, injection, automotive, pipes and fittings, electrical/electronics, cable, plate.

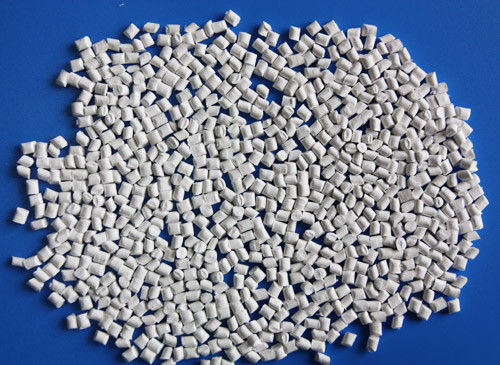

Our TiO2 (titan) high white masterbatches; It is unique with its strong covering, strong whitening and high heat resistance. In line with the demands of our customers, the concentration density is between 30 percent and 70 percent. Usage areas; Kitchen products, Film, Injection, White goods and household appliances, Pipes and fittings, Electric / Electronic, PVC, Cable

It is a process application that provides efficiency to plastic polymer groups and helps the performance of products. ANTIBLOCK ADDITIVES: It creates a gap between the polyolefin films and prevents them from sticking to each other and blocking. ANTIMICROBIAL ADDITIVES: It prevents the growth of microorganisms such as bacteria and fungi on the polymer. SLIP ADDITIVES: Enables easy opening of polyolefin films by allowing them to slide on each other. ANTISTATIC ADDITIVES: Prevents Static electricity accumulation on the surface of the plastic. FLAME RETARDANT ADDITIVES: Prevents the plastic from igniting or from advancing even if it is ignited. UV STABILIZER & ABSORBER ADDITIVES: Delays the deterioration of the structure and appearance of the polymer with the effect of UV over time, depending on the rate of use. ANTIOXIDANT ADDITIVES: Delays the deterioration of the structure and appearance of the polymer over time with the effect of air oxygen and UV, depending on the rate of use. OPTICAL WHITENING ADDITIVES: When the whiteness of the plastic is not enough, it makes it a little whiter and brighter.

No represented companies found.

The company has no registered brand information.

TR

TR