| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

RÜSTEM POLAT PLASTİK EĞİTİM DANIŞMANLIK MÜH. İTH. İHR. SAN. VE TİC. LTD. ŞTİ.

Cumhuriyet Mah. Hisar Cad. No:40/3 / Nilüfer / BURSA / TÜRKİYE

|

Contact Info: +90 532 371 1729

|

Hall: 12A

Stand: M2

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

The first and only Training and Consultancy company on Plastics. The main purpose of our organization is to eliminate the basic material knowledge in the field of polymers, to ensure efficient use of resources by raising awareness in the sector, and to increase added value on a country basis by ensuring more efficient use of plastic materials. In addition to Training and Consultancy, our other field of activity is to provide guidance to companies that do not have their own R&D units by carrying out product/project development.

Topics such as concepts related to plastics, plastic groups, purposes of use, advantages, mechanical and thermal properties, performance and price balance, degradation properties and protection methods, fillers used and the properties they impart, processing methods, test methods and color concept are discussed in general terms.

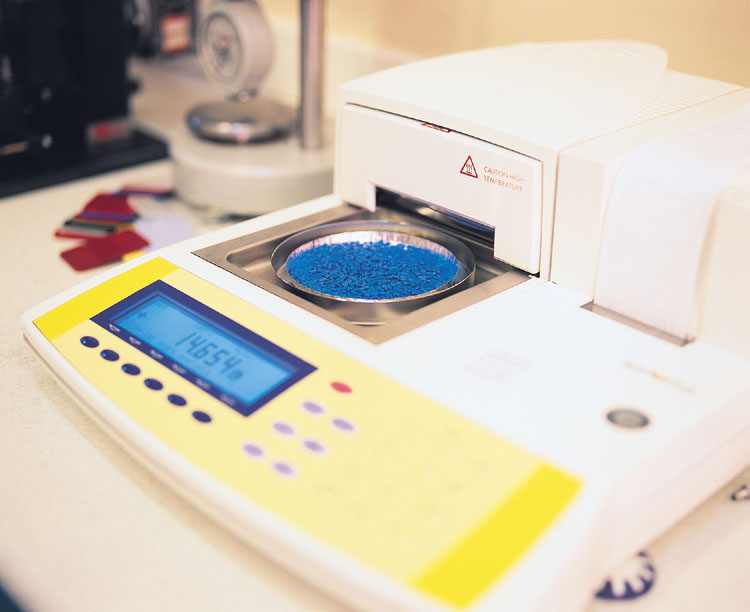

The procedure of selecting appropriate raw materials starting with the design process in enterprises, determining the basic input quality tests to be carried out for the selected material, performing the tests according to appropriate standards, preliminary preparations and methods of performing the tests, comparison of standards and standard printing samples, interpretation of the results and decision making, basic polymer concepts and quality definition issues are discussed in detail.

The details of the injection process, which includes the stages of selecting, processing and producing the appropriate material starting with the design process in the enterprises, are given in this training. Raw material, knowing the injection machine, mold and mold features, machine mold suitability, production settings are touched upon in-house production issues. The side processes, material drying, in-house activities and control issues are reinforced. In the conclusion section, the definition of approximately 30 errors that occur in injection production, their possible causes and elimination methods are discussed in detail.

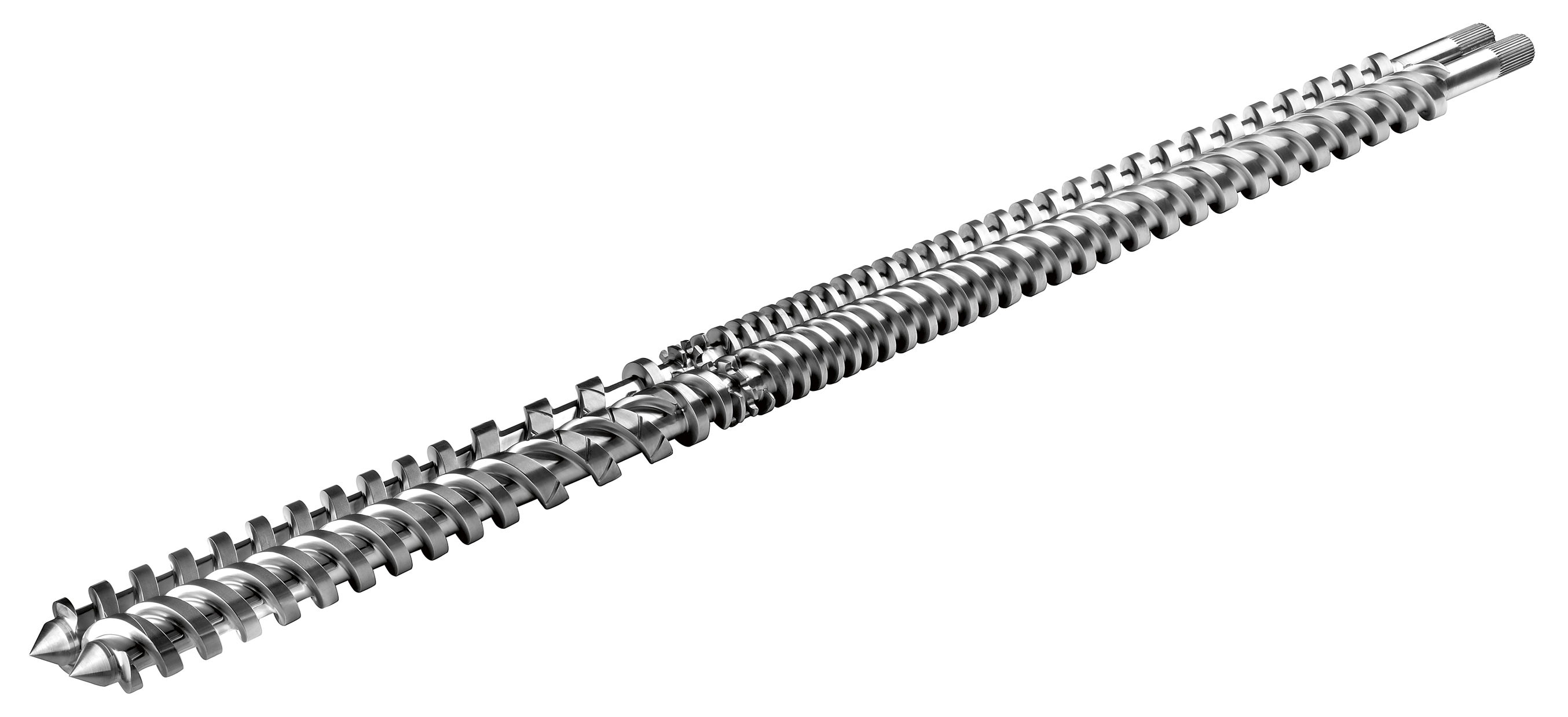

Details of the compound extrusion process as the basic processing technology, machine selection in the compound processing process, determination of auxiliary equipment, establishment and management of the business, material selection, formulation, R&D logic, additives used, additive properties, product development and product control methods are discussed in detail.

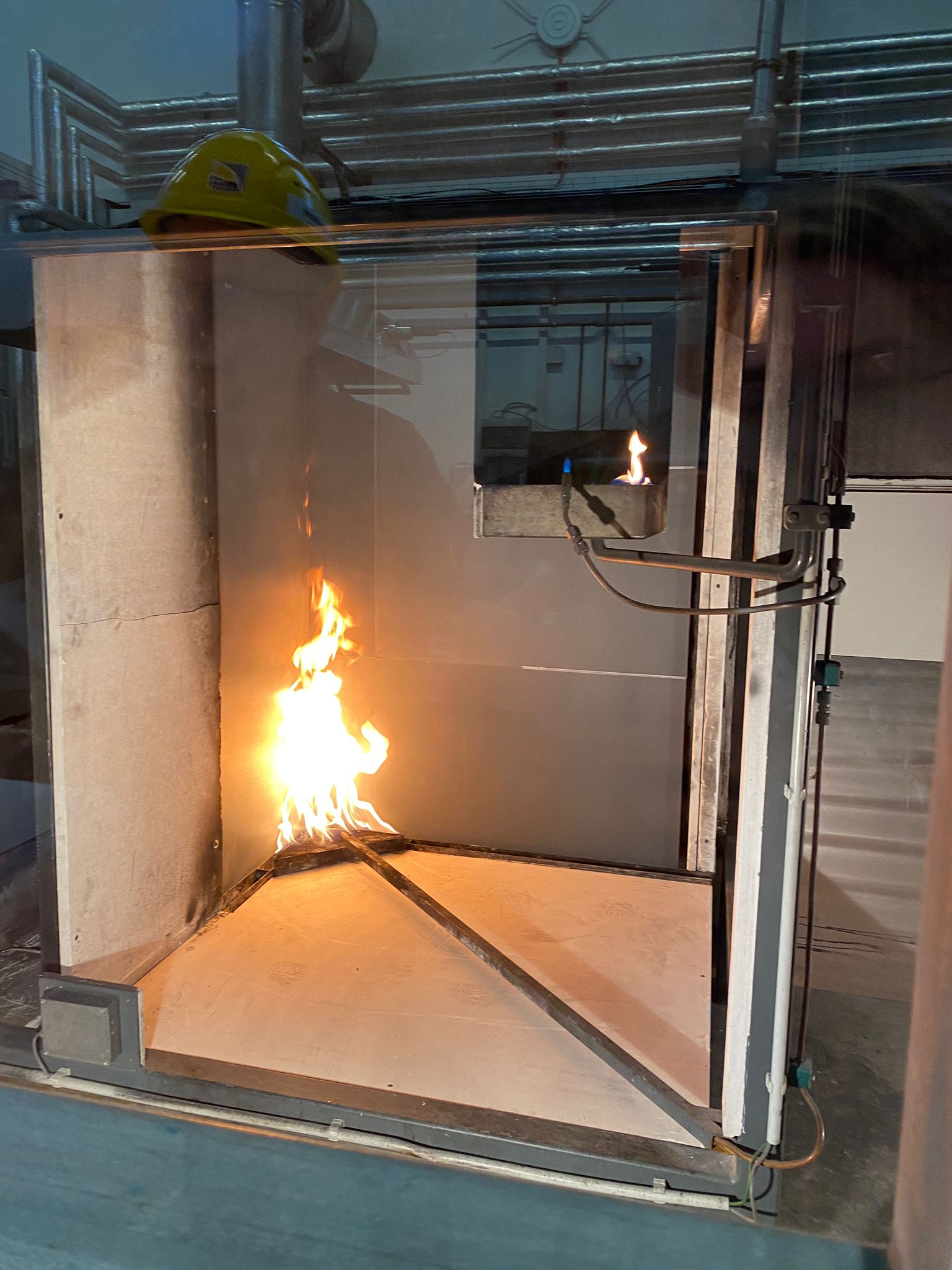

The reactions and results of carbon-rich plastics with flame source and environmental oxygen are discussed separately, considering plastic types and their sectoral uses. Combustion processes, intrinsic non-flammability, late ignition, oxygen index, smoke and smoke density, late ignition, protection methods, FR additives used, smoke inhibitors, formula creation, compound logic, sectoral applications and examples are discussed. The content covers all sectors.

The two basic groups of composites, which are the advanced technological application forms of the polymer sector, namely Thermoset and Thermoplastic material groups, are discussed together. The characteristics of both groups, production methods, matrices used, reinforcement materials and fillers are given, possible production errors are defined and composite joining techniques and their non-destructive detection methods are mentioned. Composite knowledge and technological importance are reinforced by giving examples of applications of composites in different sectors.

In order to recycle plastic products that are wasted or waste as a result of plastic processes or that have completed their economic life due to their use, both physical and chemical recycling methods are evaluated, and the processes that these identification and separation methods should be applied and followed are given with examples from different material groups, with an approach that prioritizes environmental awareness and country economy.

The effects of material flow properties, machine and pre-preparation times on process efficiency in different extrusion applications (pipe, profile, hose, sheet, film, cable, fiber) are discussed and process errors that occur depending on these variables are discussed and their elimination methods are given.

It includes support and guidance in determining new investment areas, sectoral feasibility studies, equipment selection and guidance, infrastructure studies and business organization, laboratory establishment, masterbatch facility establishment, compound facility establishment and commissioning, plastic recycling and applications, foam and extrusion line establishment, dosing and auxiliary equipment selection, personnel training. Our company offers its services to our entrepreneurs who are considering investing in the plastics sector, starting from the training phase, in the entire process of determining the right market, selecting the right machines according to the need and developing the right products, with a full partnership logic.

Filled products (mineral powders, glass fiber, glass beads), fire retardancy (FR), impact additive products, mechanical property development, paint problems, development of products in accordance with sectoral standards and all kinds of formula creation, quality and efficiency are our works presented in the field. Although the topics seem to concern mostly masterbach and compound companies at first, such developments to be made in order to increase added value in all other sectors, especially in businesses that manufacture from powder, are inevitable.

No represented companies found.

- RÜSTEM POLAT

TR

TR