| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

SAREM MAKİNA SAN. VE TİC. LTD. ŞTİ.

34522, Akçaburgaz Mah. 3108 Sok. No: 12 / / İSTANBUL / TÜRKİYE

|

Contact Info: +90 530 407 9520

|

Hall: 7

Stand: 707B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Sarem Machinery is one of the largest manufacturers of plastic pipe extrusion lines based in Istanbul, Turkiye. Our R&D, project preparation, processing, assembly lines, and testing departments operate within our factory, which spans 7,000m² of enclosed space in Istanbul. We produce machinery for PP, PE, PVC, PPR-C, corrugated, drip irrigation, PEX-A, and multilayer pipes, as well as injection molds for fittings. With the advantages of our mechanical engineering background, Sarem Makine has reached the quality and efficiency levels of major European companies. We offer machines with the same quality and speed, but with lower energy consumption. Our team members continuously enhance their expertise by prioritizing innovative technologies. Over the years of machinery production in our factory, we have installed more than 300 pipe extrusion lines in 40 countries.

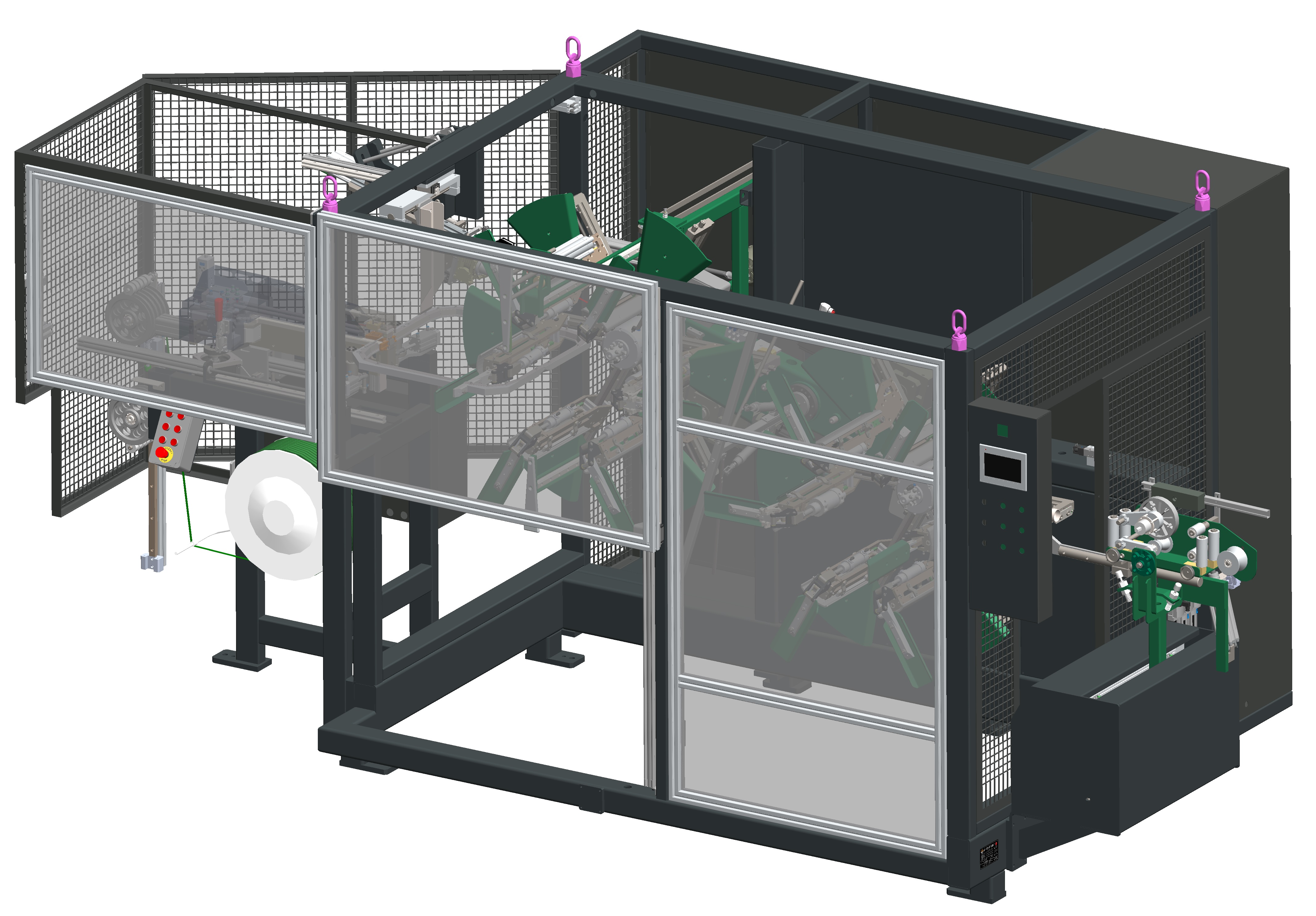

Sarem Machinery manufactures a variety of fully automatic coilers. We design and produce a wide range of fully automatic coilers for different pipe production lines and can offer customized coilers according to customers demands. The automatic coilers can automatically coil, strap, film, and eject coiled pipe. We can provide special coiling and packing solutions to our customers based on their pipe lines, such as PE, PERT, PEX, irrigation and more. In our fully automatic coilers, we utilize servo motors, drives, and PLC s from well-known brands like Omron and Beckhoff.

Sarem Makina manufactures one of the fastest PP and PVC automatic belling machines in the world. We offer different machines according to customers production capacity. These machines can bell PP and PVC pipes suitable for indoor and outdoor sewerage and pressure pipes between 32mm and 250mm. BECKHOFF touch screen and PC are used to operate the machine. Thanks to the special internal heating system using infrared heater lamps, the electricity consumption of the machine is minimized. In addition, infrared heater lamps provide homogeneous heat in the pipe. In belling machines, hydraulic systems are used to make the belling process faster and more reliable, and pneumatic systems are used in the moving parts.

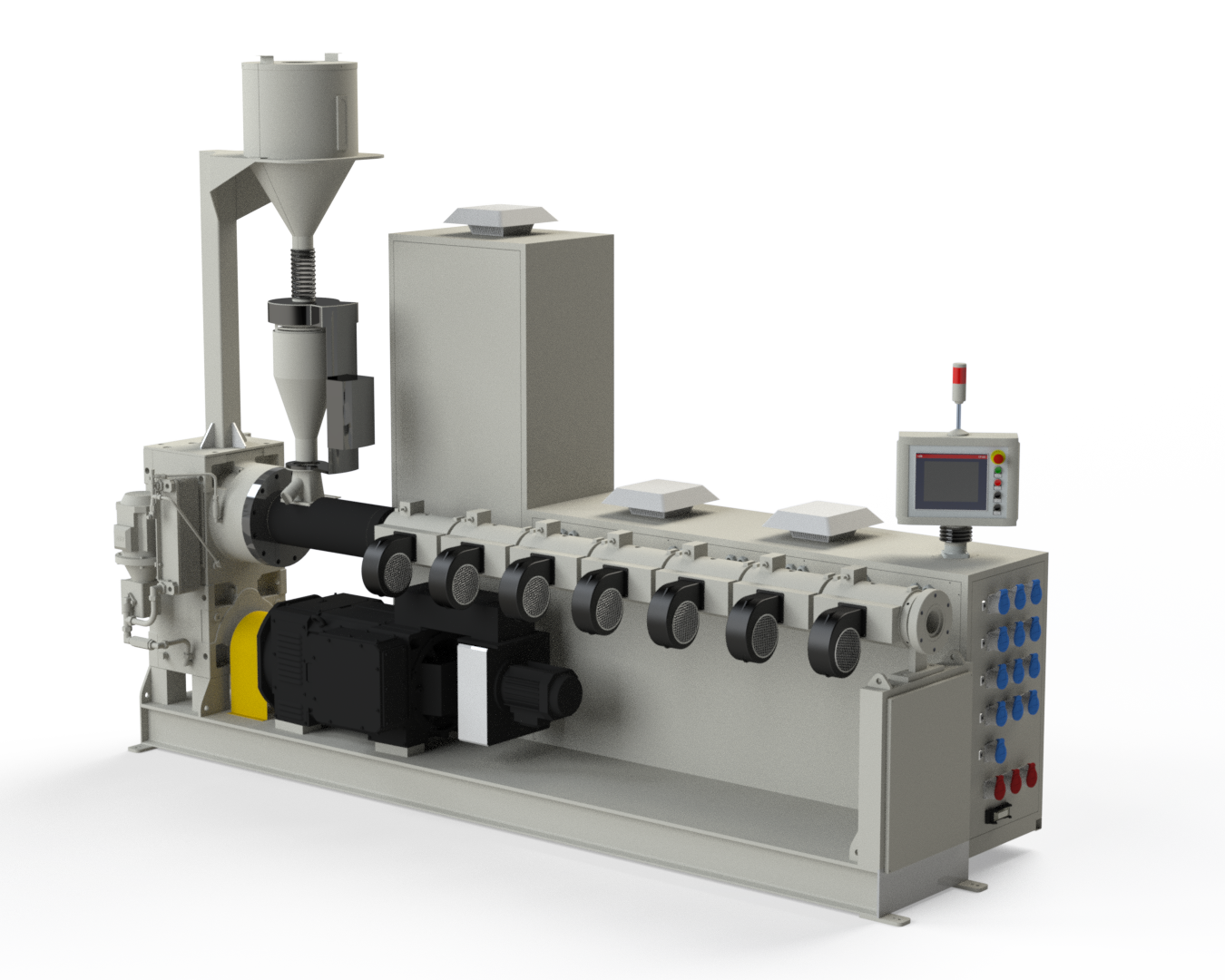

A plastic extruder is a machine that melts plastic raw materials by heating and then shapes them into a continuous flow with a specific shape or form using a screw system. Extruders can have various configurations, such as twin-screw, single-screw, co-rotating, counter-rotating, intermeshing, and non-intermeshing types. Sarem Makina develops solutions based on the demands and needs of its customers.

The cutter is used to cut products emerging from the extrusion process into specific lengths. By cutting the products to the desired sizes, the cutter ensures that the final products are standard-compliant and suitable for further processing. This enhances the efficiency of the production process and prepares the products for end-use.

In extrusion lines, the vacuum tank ensures proper cooling and shaping of the products. By applying vacuum to the material during extrusion, the vacuum tank removes surface air bubbles and defects. This process ensures uniform cooling and maintains the correct diameter of the products, resulting in high quality and consistency.

The manually operated winder, controlled by the operator, facilitates the neat winding of pipes, making them easier to transport and store. We offer dual and single-type manual winders for polyethylene, PEX, PERT, and multilayer pipe extrusion lines. In our manual winders, pipe speed synchronization is automatically adjusted using torque control.

No represented companies found.

The company has no registered brand information.

TR

TR